Motivation

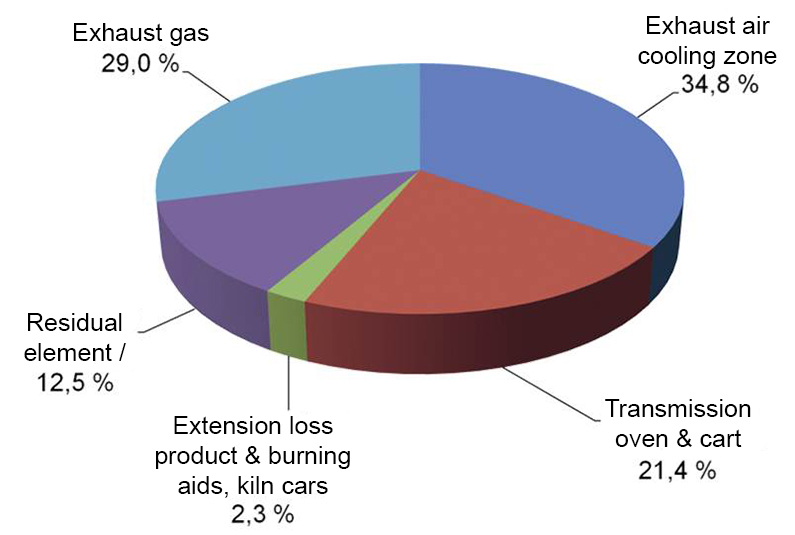

In industrial thermoprocessing plants, energy losses are caused by thermal insulation, by exhaust gases or cooling air, by heat radiation losses as well as by the residual heat of the material to be heated and the auxiliary materials. The energy efficiency deteriorates during operation due to ageing of components, e.g. the furnace insulation. Countermeasures can be taken if the energy balance is measured regularly. This is very costly.

For the user many industrial furnaces are a black box on the inside.

The temperature distribution as well as the composition and flow velocity of the furnace atmosphere can only be determined insufficiently. However, these parameters have a great impact on the product quality after heat treatment.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth