Motivation

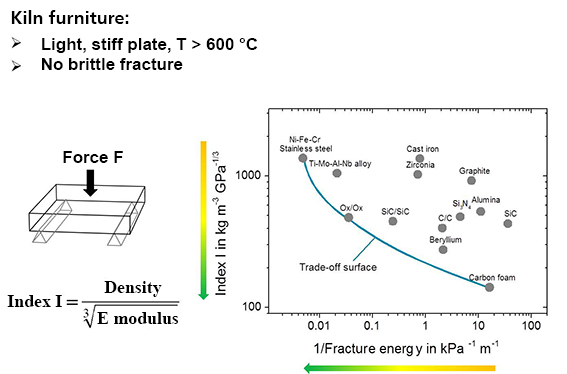

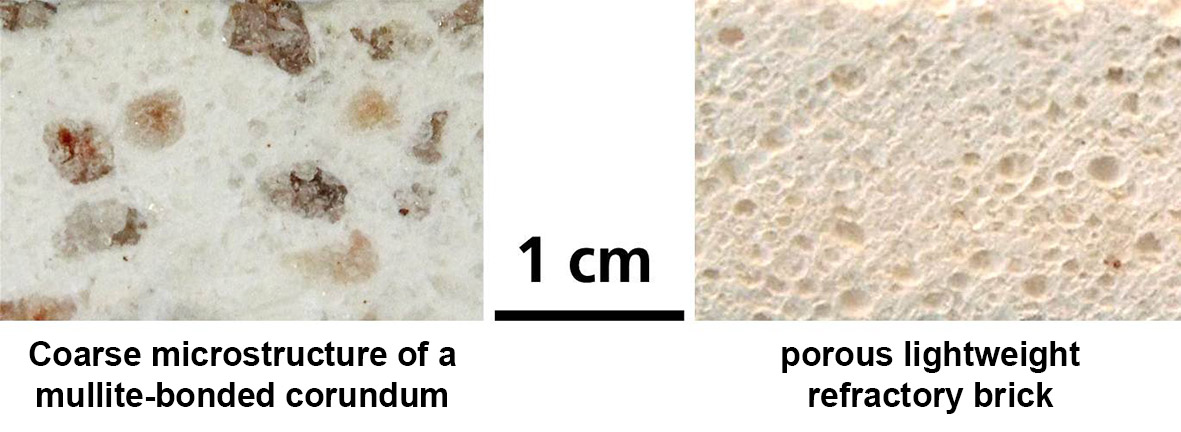

A large number of different high-temperature materials is used in furnace construction, such as refractory linings, high-temperature steel alloys, heating elements or kiln furniture.

The exact knowledge of their high-temperature properties is a prerequisite for making an optimal material choice. For example, these properties are used in the calculation of material indices, which enable materials to be evaluated with regard to specific requirements.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth