In order to achieve the desired product quality during thermal treatment, the green bodies must already possess suitable properties. In general, it is necessary for the green parts to be as homogeneous as possible on the micro, meso, and macro scales. The reasons for this are as follows:

- Microscale: The individual particles must be arranged as uniformly as possible. Otherwise, there is a risk of preferential sintering of neighboring particles and premature grain growth.

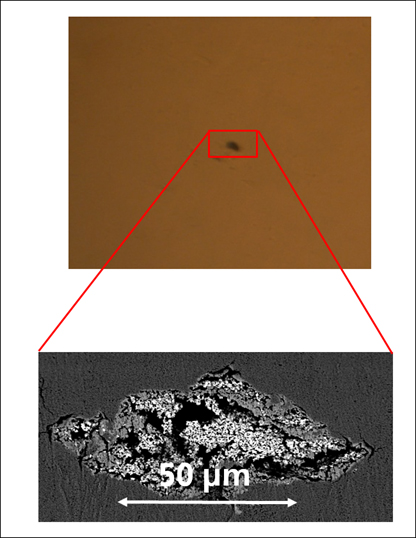

- Mesoscale: In sintered parts of this size, structural defects such as inclusions, large pores, or cracks are often present, which control the fracture behavior. Even a few structural defects per cubic centimeter lead to a deterioration in strength and reliability.

- Macroscale: The density must be as constant as possible throughout the component, otherwise there will be uneven shrinkage and distortion during sintering. Distortion is associated with a loss of quality or an increased need for post-processing.

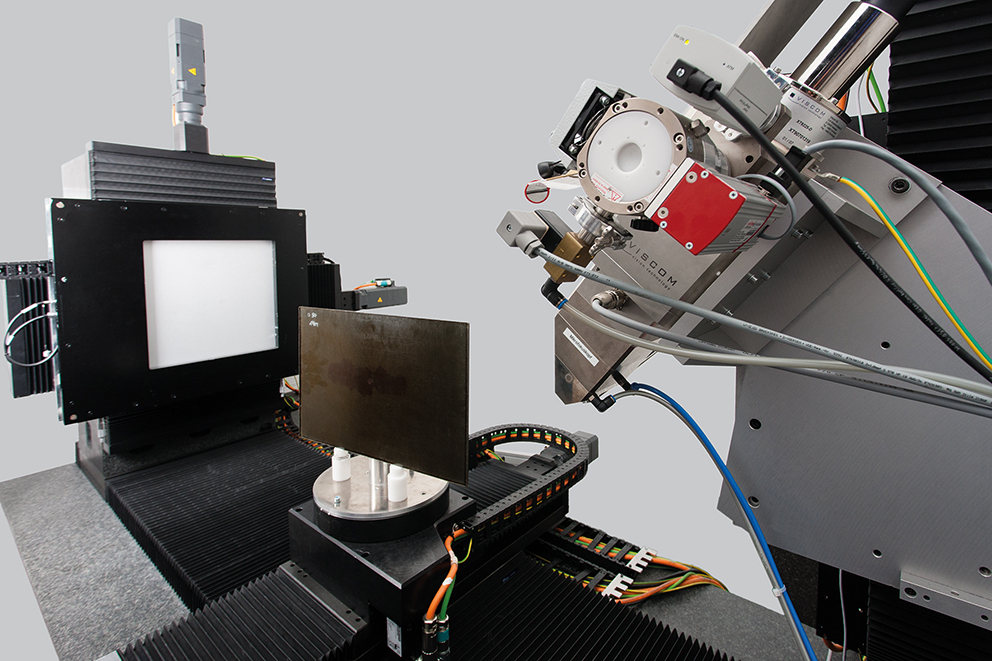

A careful assessment of the green body quality significantly reduces the complexity in the development of powder metallurgical manufacturing processes. Optimization steps in the areas of raw material selection, mass preparation, and shaping can then be largely separated from the optimization of thermal treatment and final processing.

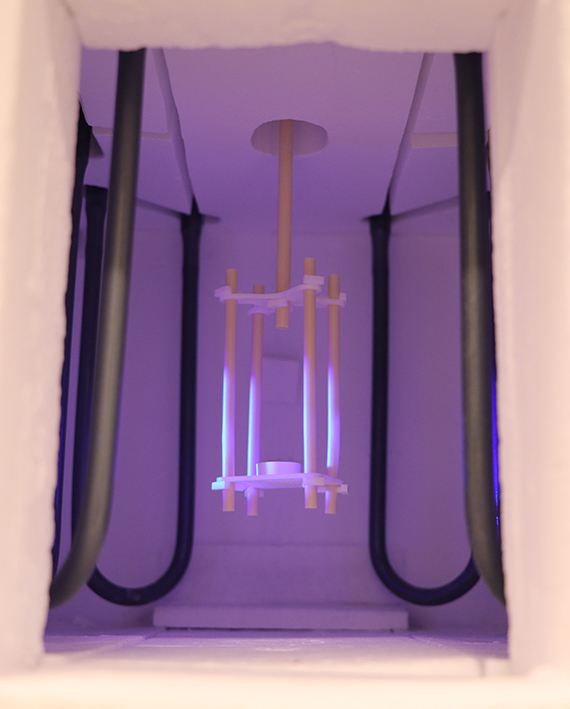

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth