The sintering of green bodies is measured in-situ with high reproducibility at Fraunhofer Center HTL and subsequently optimized. The result of sintering is strongly influenced by the furnace atmosphere for many materials. Suitable ThermoOptical Measurement Systems (TOM) are available at the HTL for most technically relevant furnace atmospheres and temperature ranges. In this way, sintering can be carried out in graphite-, molybdenum disilicide-, or tungsten-heated measurement furnaces. Inert gases, oxidizing or reducing gases - including 100% hydrogen - can be used as furnace atmospheres. Some TOM systems can be operated under vacuum or overpressure (up to 30 bar). The furnace atmosphere in gas-heated furnaces can also be accurately reproduced. Matching the furnace atmospheres between the production furnace and the TOM system used is extremely important because only then can the sintering conditions optimized by the TOM system be transferred to the production furnace. In addition, temperature matching of the affected furnaces is usually carried out using specially calibrated temperature measurement rings.

Sintering

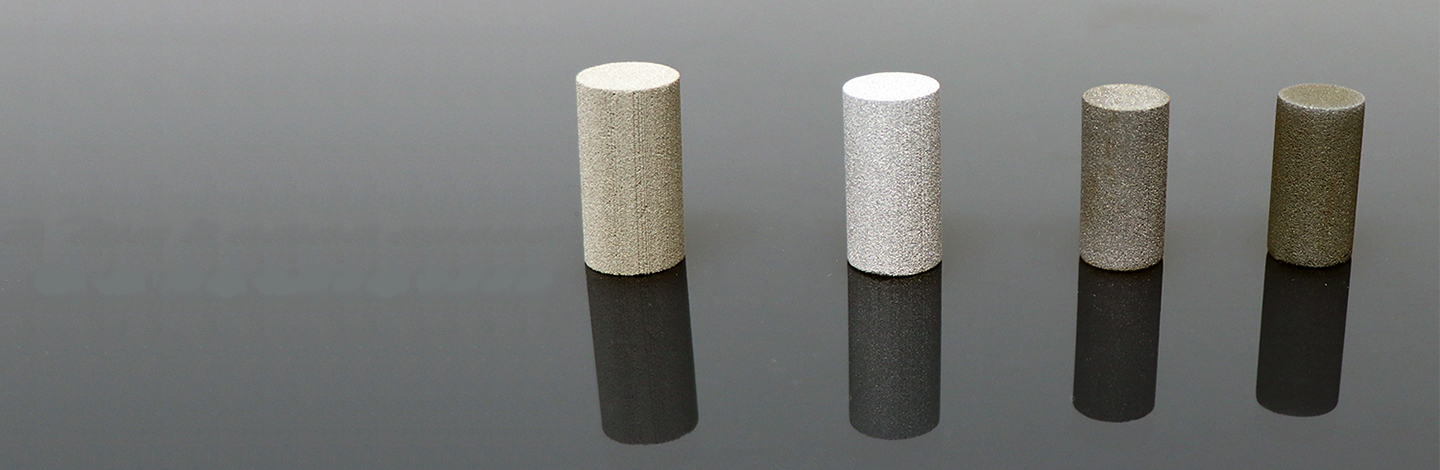

The shrinkage in sintering processes can be measured with very high reproducibility using the optical measurement principle of TOM systems [1]. The measurement resolution of the TOM systems in the latest generation of systems is 0.1 µm. The reproducibility for sintering investigations is 0.02%, which is significantly better than with comparable methods. The high accuracy is also used to measure the distortion of samples during sintering. This allows porosity differences in green bodies to be measured by taking test samples and subsequently sintering them which is more accurate than with conventional measurement methods. However, primarily, the sintering kinetics is determined by carrying out several sintering runs with different temperature-time cycles on the same green samples. A kinetic model is calculated from the measurement data using a robust numerical method, which allows the sintering shrinkage to be predicted for any temperature-time cycle within the measured range [2]. Simple optimization of the sintering cycle is already possible with this kinetics model.

[1] Raether, F.: Current state of in-situ measuring methods for the control of firing processes. J. Am. Ceram. Soc. 92, 2009, pp. 146-152.

[2] Raether, F.: The kinetic field - a versatile tool for prediction and analysis of heating processes, High Temperatures-High Pressures, 42.4, 2013, pp. 303-319. (see abstract)

Further in-situ measurements are necessary for more detailed investigations, such as regarding distortions due to gravity or temperature gradients. The creep behavior of the green samples during sintering is determined by cyclic uniaxial loading tests. The uniaxial viscosity and viscous Poisson ratio are determined as a function of sintering state and temperature from the measurement data. The thermal conductivity can also be measured in situ during sintering using specially developed laser flash methods with the TOM systems available at the HTL [3]. Together with the kinetic model, this data is incorporated into a coupled FE model. The temperature gradients in the component are first calculated for each time step during sintering from the local temperatures. The local sintering shrinkages for the corresponding time step are then determined from the FE simulation of the local temperatures, and stresses and deformations are calculated from external forces such as gravity and friction. The thermal expansion of the material and, if necessary, interactions with the furnace atmosphere are also considered in the FE models. In this way, measurement results from simple small samples are transferred to large and complex components. Sintering conditions can then be optimized through the FE simulations to fulfill geometric requirements for individual components and to avoid the formation of critical stresses during heat treatment.

During densification, thermodynamic driving forces can cause originally homogeneous green bodies to sinter unevenly or for different phases to separate. At the end of densification, there is increased grain growth, which, like the thermodynamic segregation effects, impairs material properties. Inherently homogeneous sintering methods are being developed at the HTL to avoid such adverse mechanisms. The methods aim for homogeneous microstructures and high reliability of the sintered materials.

[3] Baber, J.; Klimera, A.; Raether, F.: In situ measurement of dimensional changes and temperature fields during sintering with a novel thermooptical measuring device, J. Eur. Ceramic Soc., 27, 2007, pp. 701-705. (see abstract)

Grain growth at the end of the sintering process can be investigated using TOM systems. It is exploited that the creep resistance of many powder metallurgy materials depends on the grain size. The cyclic loading tests mentioned in the previous section are used to measure changes in creep resistance due to grain growth during the hold time, so that this can be taken into account when optimizing sintering conditions. TOM methods can minimize deteriorations in microstructure homogeneity during sintering. However, defects already present in the green body cannot be eliminated during thermal treatment. Therefore, it is recommended to check the quality of the green body before optimizing its thermal treatment. Corresponding methods for evaluating the quality of green bodies are available at the HTL.

Density fluctuations resulting from temperature differences in the furnace require specific measures. Temperature differences in the production furnace must first be registered for this purpose. Specifically calibrated temperature measurement rings are available at the HTL for this purpose. Then, temperature-time cycles can be calculated with the kinetic model to minimize density fluctuations. If necessary, the set-up for the charge may also need to be changed to minimize temperature differences. The optimization of the set-up can be supported by FE analyses.

Creep deformation during sintering can also be measured with TOM systems even at very high compressive stresses typically used in special sintering processes such as hot pressing (HP) or hot isostatic pressing (HIP). A kinetic model can also be created for these sintering processes and used for the simulation of HP or HIP sintering.

Service Offering:

- Support in the design of sintering processes (t-T profile, set-up, atmosphere)

- Optimization of sintering processes regarding:

- Avoidance of deformations, density inhomogeneities and microstructure defects

- Improvement of cost-effectiveness

- Reduction of CO2 footprint through increased energy efficiency

- More efficient filling and furnace setups

- Temperature homogeneity and atmosphere

- Provision of sintering apps that allow independent optimization of temperature cycles

- Investigation of specific issues in sintering, such as:

- Co-firing

- Reactions with sintering aids

- Melt phase formation

- Thermodynamic equilibria

- Material redistribution, etc.

- Performing sintering runs and product characterization

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth