Currently Funded Project

Motivation

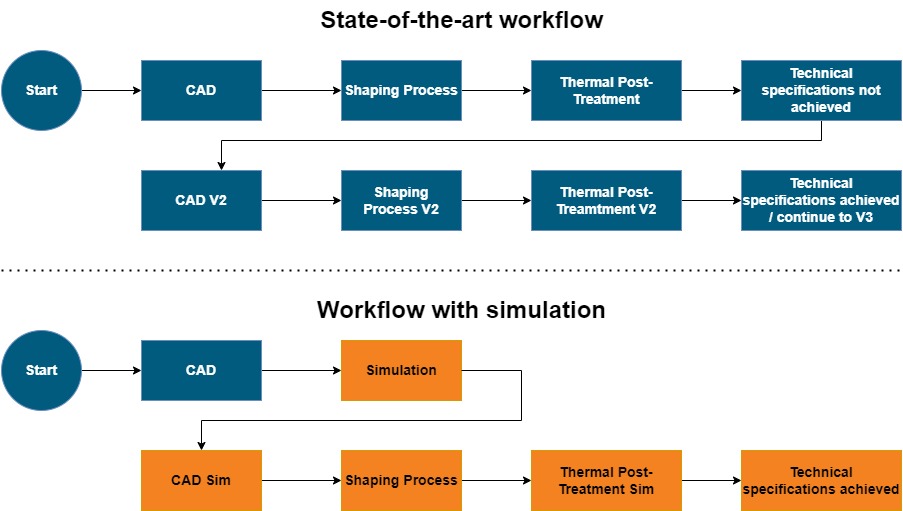

The additive manufacturing of ceramics is not yet as widespread as with metals or polymers. One of the reasons for this is the more complex thermal post-treatment of ceramic components. Currently, the thermal post-treatment of additively manufactured ceramics is optimized by several iteration loops on the complex geometries, which is not very resource and energy efficient. Improving digital design and production processes (especially thermal post-treatment) will make production more sustainable and faster.

Objective

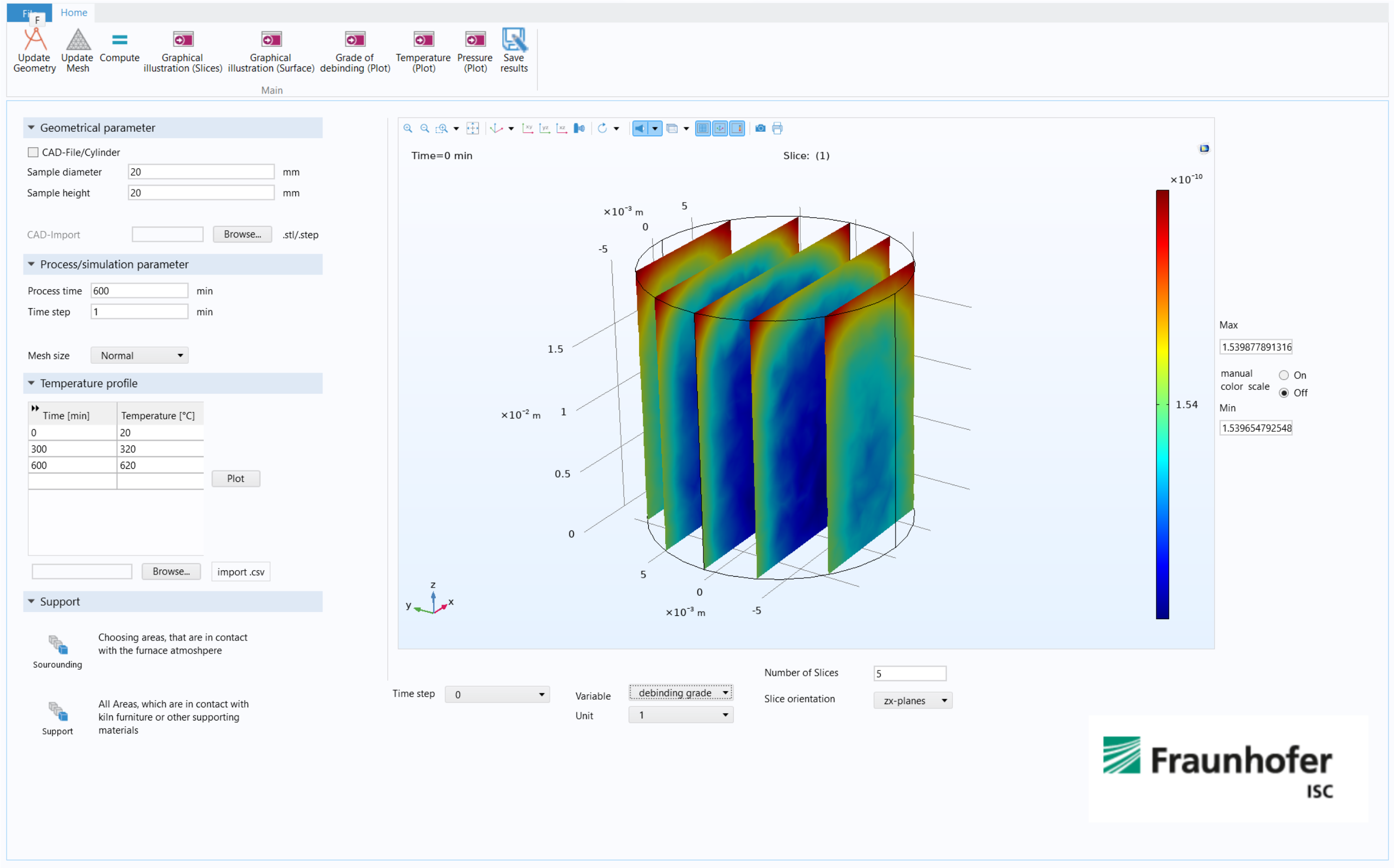

The aim of the SinSim3D project is to research and develop a simulation tool for the automated adaptation of digital data sets. This tool is intended to select optimal material and geometry-specific parameters for the thermal treatment process step of additively manufactured green bodies. The simulation is intended to avoid failures and unnecessary production loops. The simulation results make it possible to significantly accelerate the production process, avoid unnecessary energy and material consumption and enable the use of the material for complex geometries that cannot be produced with the current state of the art.

Approach

- Adaptation and validation of the thermoprocessing models to the ZrO2 material system produced by LCM manufacturing

- Systematic analysis of the thermal processing

- Development of algorithms for automatic optimization of the temperature cycle in conjunction with anticipation of mould distortion

Project Data

| Project Duration | 1.7.2024 - 30.6.2027 |

| Funding by | Bavarian State Ministry of Economic Affairs, Regional Development and Energy |

| Funding Amount HTL | 181,000 Euro |

| Project partner | CADdent GmbH |

| Projekt coordination | CADdent GmbH |

| Projektmanagement at HTL | Heiko Ziebold |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth