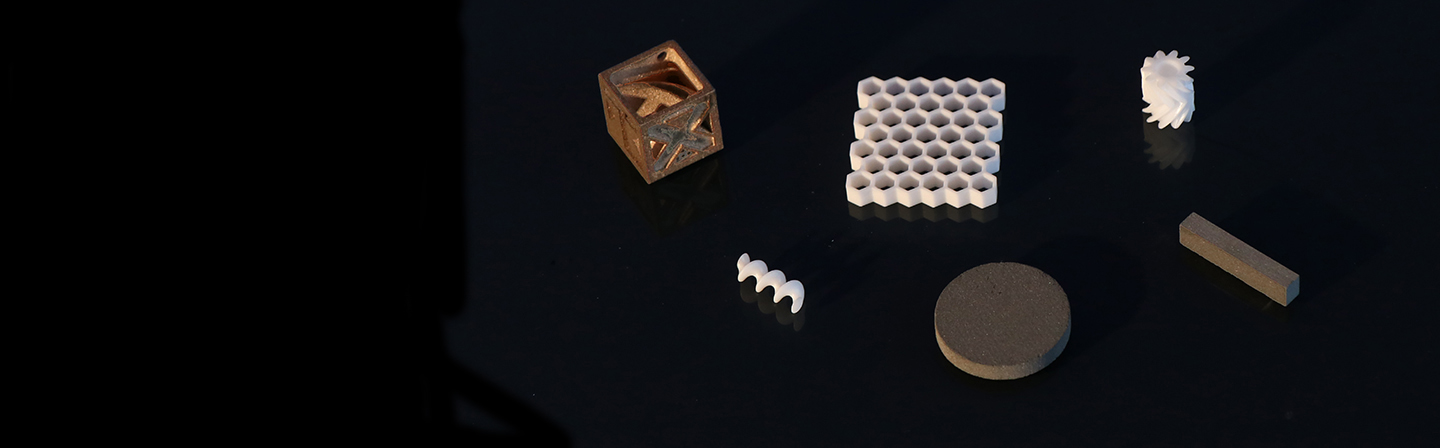

Fraunhofer Center HTL develops and produces components made of ceramics, metals, and metal-ceramic composites through 3D printing processes. Standard materials include aluminum oxide, zirconium oxide, silicon carbide, and steel. The technology field of additive manufacturing encompasses the development of new material systems, manufacturing processes and equipment, the production of prototypes and small series, as well as the quality management of additively manufactured components.

The development of new material systems involves the formulation and synthesis of feedstocks for 3D printing. The goal is to adjust the processing properties of the feedstocks for the specific 3D printing process so that high-quality components can be produced while also achieving the desired material properties requested by the customer. Examples include adjusting the flowability of powder blends or adapting the processing properties of slurries for additive manufacturing.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth