Fraunhofer Center HTL develops customer-specific devices or device components for component production and measurement. Together with the customer, a task clarification is carried out, in which the requirements and framework conditions are precisely defined. The result of the task clarification is a specification sheet, which contains all relevant data/characteristics of the system to be developed. From this, the HTL creates a concept for the specific device. Already existing commercially available device or device components are used as effectively as possible. The concept is coordinated with the customer.

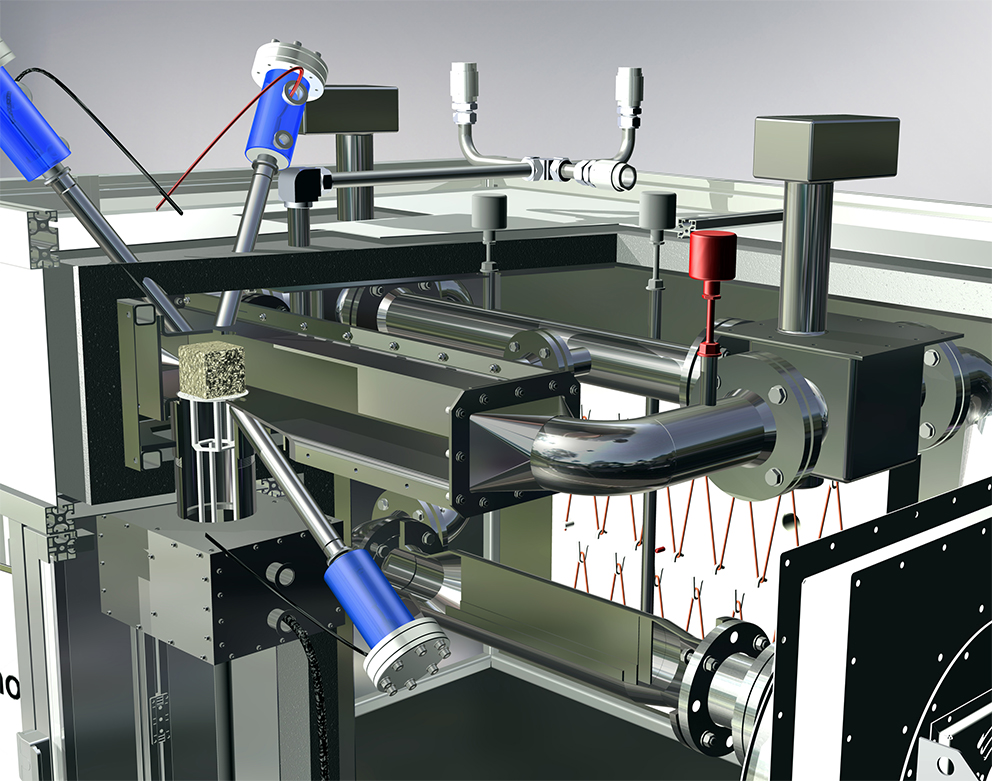

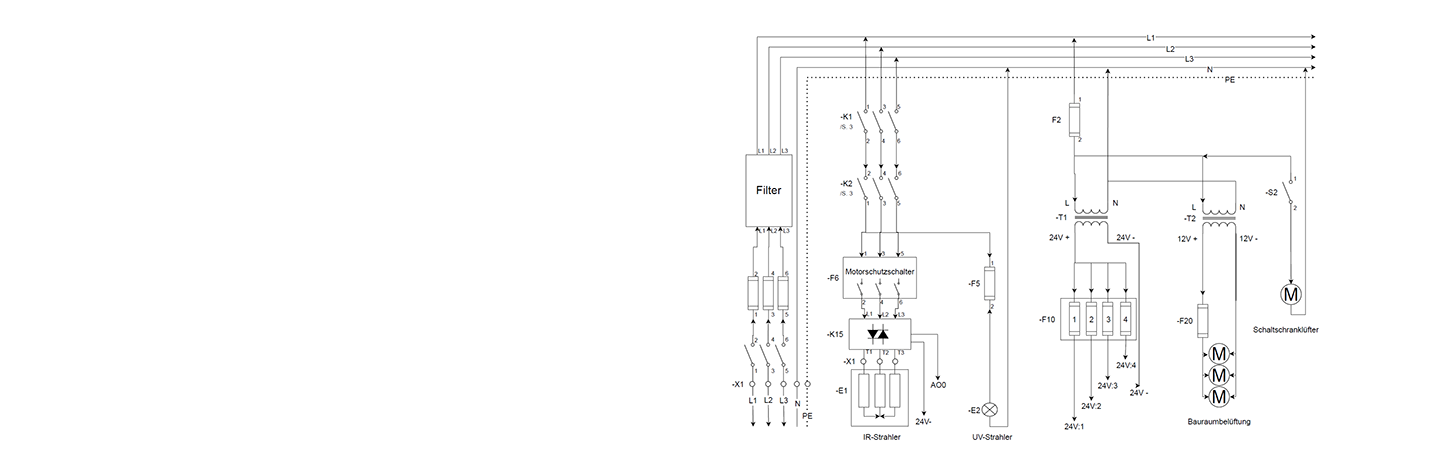

Subsequently, the thermal, mechanical, and electrical design of the machine components is carried out. The necessary CAD plans and the specifications for the device software are created. If necessary, FE simulations are carried out to verify the design and identify critical elements. In addition, a hazard analysis is performed. The construction of the device is carried out with commercially available standard components as well as custom-made parts produced in the machining center, 3D printers or workshops at the HTL. The competencies at the Center of Device Development (CeDeD) of Fraunhofer ISC are also used for device engineering. If necessary, an EU declaration of conformity and CE labelling are carried out. After internal acceptance, the device is handed over to the customer.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth