Currently Funded Project

Motivation

Ceramic production is extremely important for numerous technical products. However, it is at the beginning of the production chain and is under strong price pressure internationally. It also suffers from a shortage of labor. Automation and digitalization according to Industry 4.0 standards would significantly increase the future viability of the European ceramics industry, but are currently difficult to implement in the small-scale manufacturing processes, so that a significant gap has developed compared to other industries.

Objectives

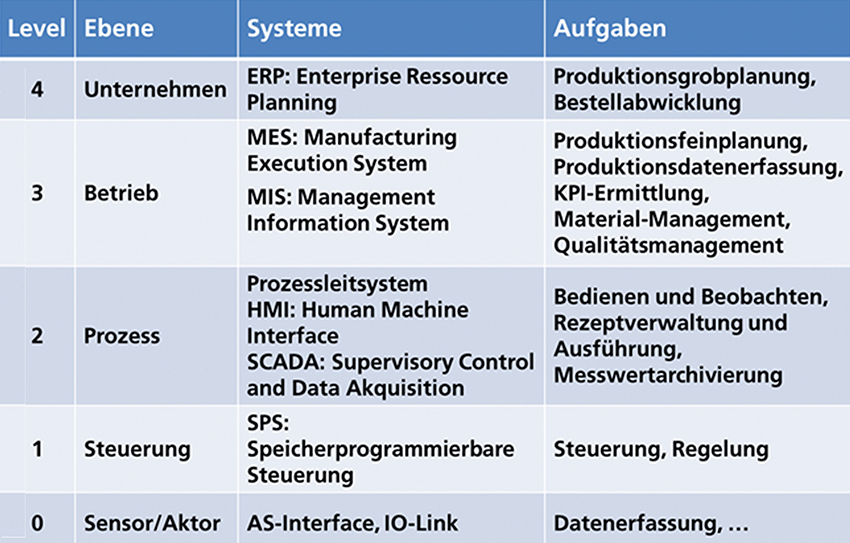

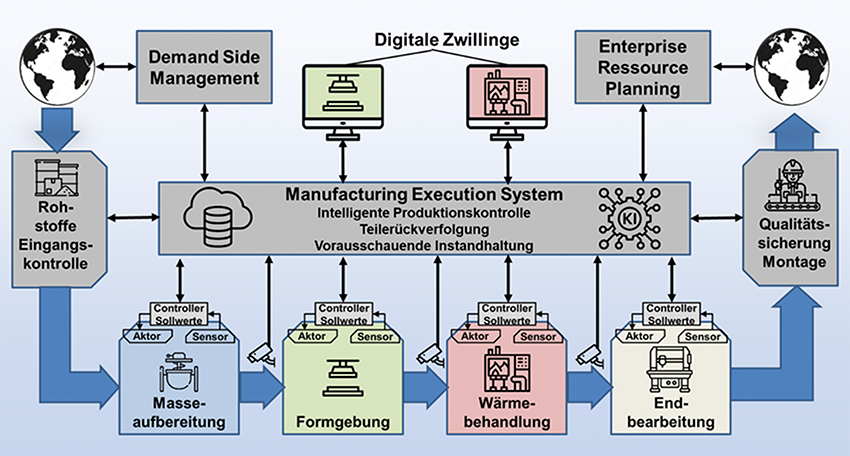

This project therefore aims to develop methods that enable the efficient introduction of Industry 4.0 methods in the ceramics industry. The performance of these methods will be demonstrated up to the level of a process control system (Level 2) on an existing production line for ceramic fibers at the HTL. Industry 4.0 methods for product tracking and predictive maintenance are also to be implemented and tested there. In utilization projects based on Ind4Ker, these methods will then be transferred to other ceramic companies and expanded to include methods at the level of the resource planning system (Level 3).

Approach

Using the example of the non-oxide production line of the HTL fiber pilot plant, methods are to be developed and demonstrated with which the effort required for the introduction of Industry 4.0 in ceramic production can be drastically reduced.

The tasks are divided into four work packages:

- Establishment of holistic data acquisition

- Development of data utilization and consolidation

- Optimization of comprehensive networking and communication

- Development of product tracking and predictive maintenance

Project Data

| Project Duration | 1.11.2023 - 31.10.2025 |

| Sponsoring |

Bavarian Ministry of Economic Affairs, Regional Development and Energy |

| Funding Amount | 600.000 Euro |

| Project Management | PD Dr. Gerhard Seifert / Rainer Richter |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth