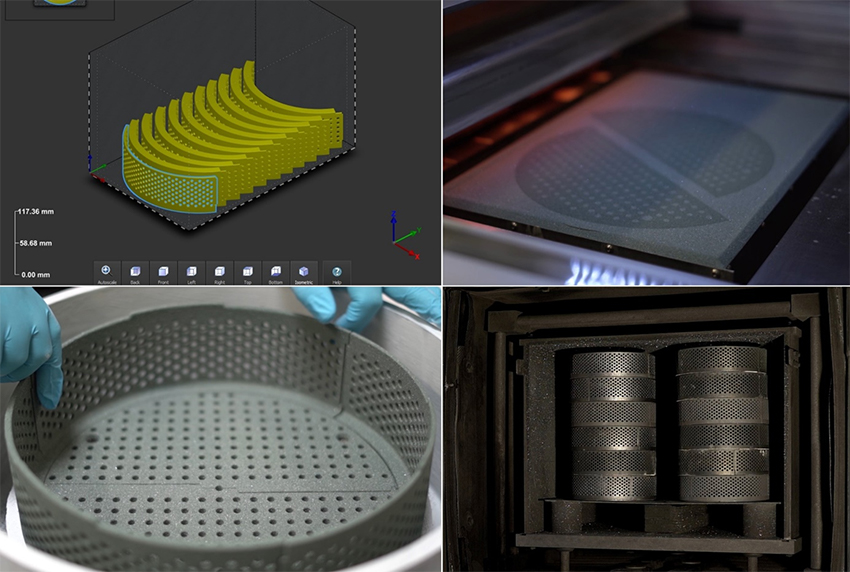

At Fraunhofer-Center HTL, components made of metal, ceramic, and metal-ceramic composites are additively manufactured using Binder Jetting with an M-Flex (ExOne) printer (see Prototyping). The parts are generated layer by layer by selectively printing a liquid binder material onto a powder bed. The components are then cured in an oven and freed from any non-printed powder, which can be cleaned and reused. The printed parts are porous after curing. In a final heat treatment step, the components are debindered and sintered. The densification can also be achieved through a melt infiltration process, which enables new material combinations.

Binder Jetting Process

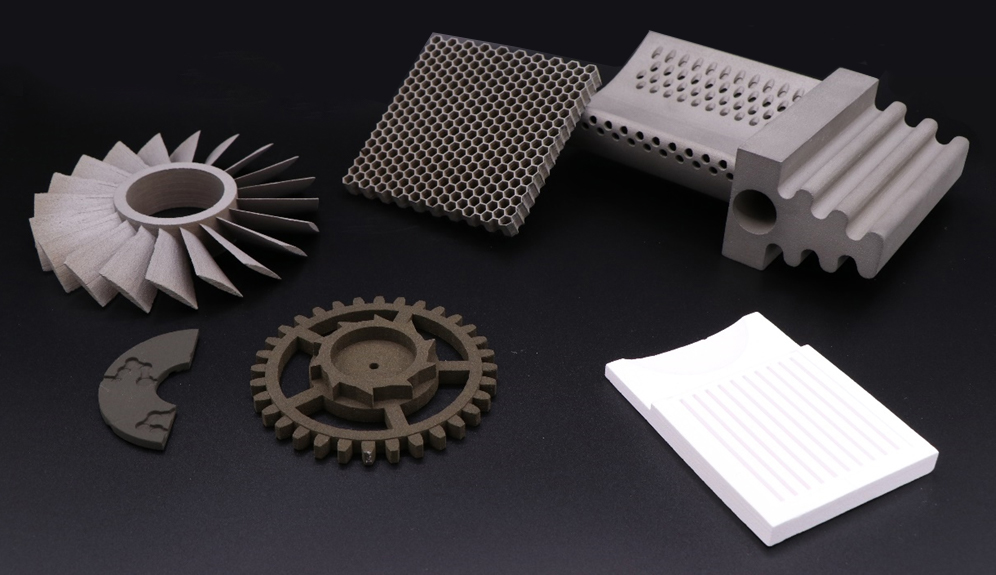

By combining the powder bed process with inkjet printing of different binder fluids and the use of various infiltration materials, it is possible to additively manufacture complex prototypes and small series in a huge range of materials, from metals to ceramics, glass, and metal-ceramic composites. The advantage of Binder Jetting lies particularly in its high productivity and cost-effectiveness, making it an attractive and more economical alternative to other methods like selective laser melting.

At the HTL, the range of services for powder bed-printed parts extends from FE-supported component design and construction to additive manufacturing of initial plastic prototypes, feasibility studies for 3D printing of individual materials, and additive manufacturing of parts made of metal, ceramic, or metal-ceramic composites. The range of services is completed by the possibility of component-specific in-situ analysis and optimization of sintering and infiltration processes using ThermoOptical Measurement methods (TOM).

- Martensitic stainless steel 420 (optionally infiltrated with bronze)

- Austenitic stainless steel 316 (optionally infiltrated with bronze)

- Nickel-based superalloys Inconel 625 and 718

- Tungsten carbide (optionally infiltrated with cobalt or nickel)

- Silicon carbide (optionally infiltrated with silicon)

- Other metallic (tungsten, titanium, aluminum, etc.) and ceramic (aluminum oxide, titanium carbide, etc.) materials on request

- Lateral resolution: 64 μm

- Layer thickness: 100 μm (equivalent to vertical resolution)

- Build volume (X, Y, Z): 400 x 250 x 250 mm

- Build speed: 3 to 12 mm corresponding to 300 to 1200 ccm per hour

Service Offering:

- Consultation for material selection as well as for ceramic- and process-oriented component design

- Design and construction of components supported by FE methods including topology optimization

- Feasibility studies

- Contract manufacturing of prototypes and small series

- Development of customer-specific starting materials for binder jetting

- Implementation and optimization of heat processes

- Sintering and/or melt infiltration of customer parts printed by Binder Jetting

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth