Many high-temperature materials are continuously exposed to strong corrosive and erosive stresses during operation. In addition to aggressive melts and slags, the predominant gas atmosphere, vapours or particles in the gas stream can lead to massive material damage.

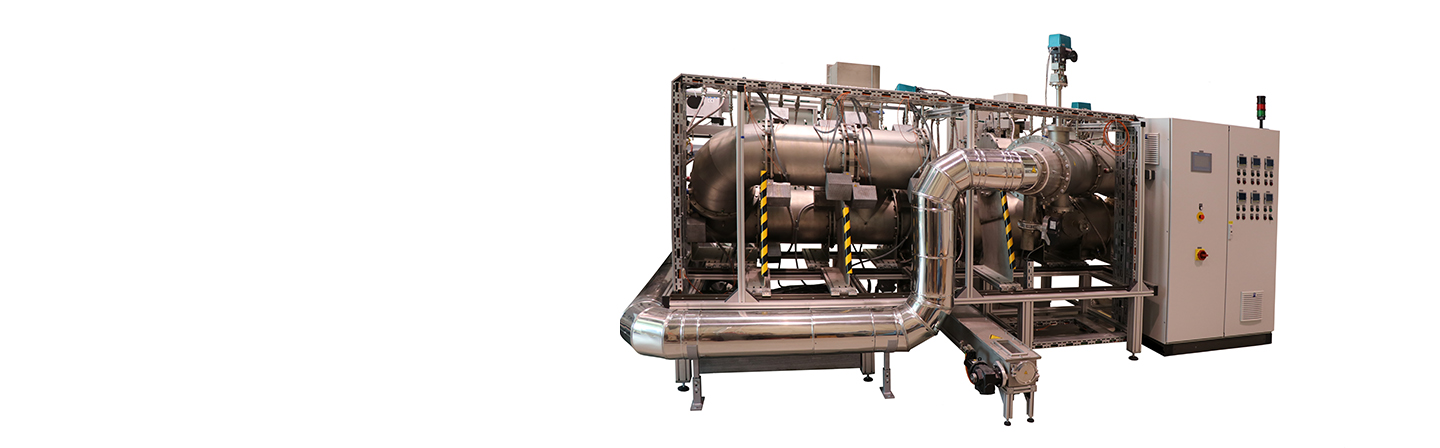

With the specially developed furnace TOM_chem, which is currently being put into operation at the Fraunhofer-Center HTL, the corrosion resistance of materials can be tested in a variable, controlled gas atmospheres at temperatures up to 1500 °C. Unique here is the possibility of injecting special dust-particles and vapours into the gas stream. This allows the study of corrosion problems under application-oriented conditions. During the exposure, weight changes of the sample material and gas composition can be monitored.

The combination of in-situ data with subsequent material studies and thermodynamic calculations enables the identification of mechanisms in the material and possible counteractive measures. The corrosion behaviour of novel materials can be tested and evaluated under application-oriented conditions with TOM_chem before using them in real high-temperature processes.

The gas atmospheres that are used in the furnace system range from exhaust gases of conventional industrial burners, reducing atmospheres to inert or special blended gases, depending on the application.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth