Currently Funded Project

Motivation

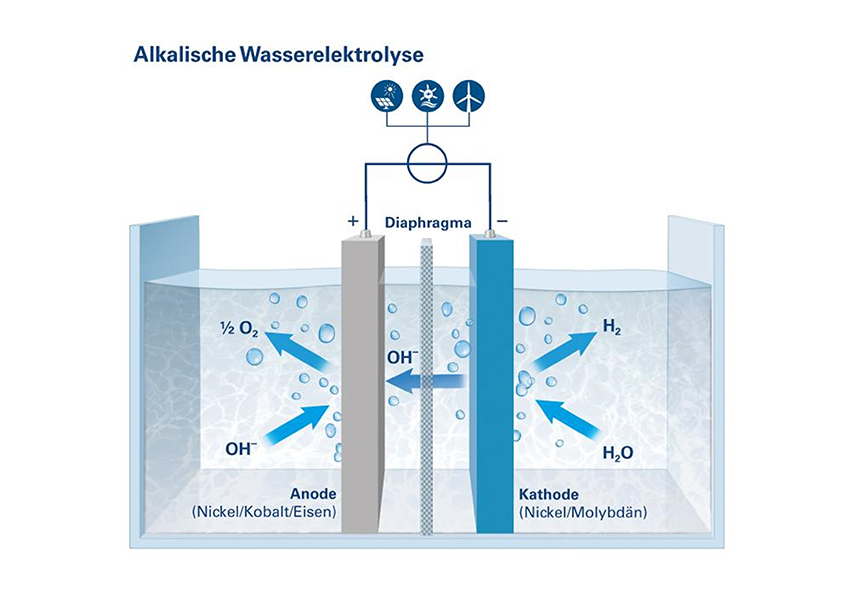

Hydrogen is an important working material for various applications and is becoming increasingly important as an energy storage medium. On the necessary scale, hydrogen is mainly produced by electrolysis. The most advanced electrolysis technologies are polymer electrolyte membrane (PEM) technology and alkaline electrolysis. PEM electrolysis achieves higher power densities but relies on rare noble metals and thus expensive catalyst materials. Alkaline electrolysis is more suitable for application at the scale required in the future, as it makes do with catalyst materials based on nickel.

Objectives

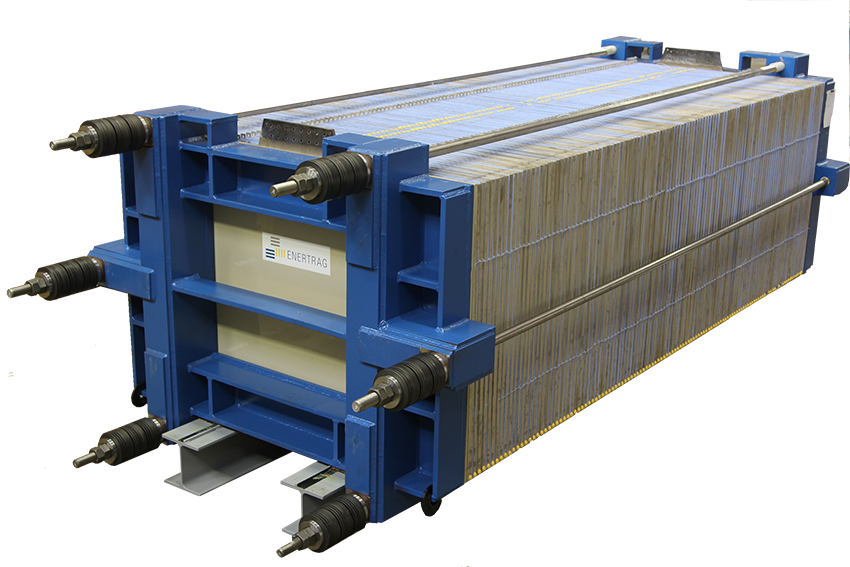

Low-maintenance or maintenance-free electrolysis cells made of ceramic materials are to be produced for alkaline electrolysis with a nominal power of between 2kW and 25kW. The ceramic materials replace the commonly used nickel-steel sheets and are intended to reduce the manufacturing and operating costs with the ceramic-specific advantages. A major advantage is the naturally high chemical resistance of ceramics in alkaline environments. By dispensing with galvanic processes, the environmental compatibility of the manufacturing process is also to be improved.

Approach

- Production of flat, surface-structured plates from sintered Si3N4 or SiC by axial pressing

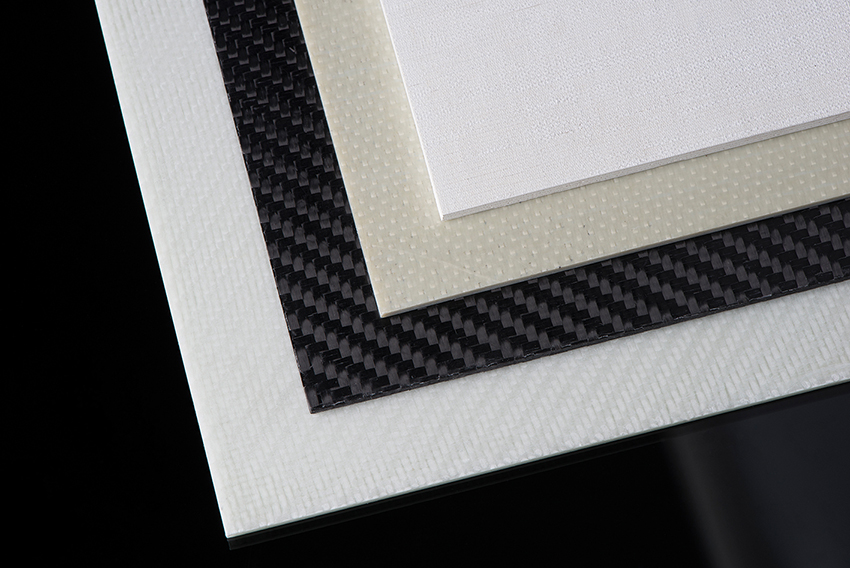

- Precursor infiltration and pyrolysis of SiC/carbon based systems, carbon felts, as well as fabrics of carbon, graphite or SiC continuous fibers

- Production of OH-conducting diaphragms based on CMC materials

Project Data

| Project Duration | 1.1.2023 - 31.12.2025 |

| Sponsor |

Bundesministerium für Wirtschaft und Klimaschutz |

| Funding Amount HTL | 395.000 Euro |

| Project Partners | ostermeier H2ydrogen Solutions GmbH PS-HyTech GmbH Paul Rauschert GmbH & Co. KG Forschungszentrum Jülich |

| Project Coordination | PS-HyTech GmbH |

| Project Management at the HTL | Wolfgang Bernstein |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth