TOM_dry is used for the analysis and optimization of drying processes. Drying is ecessary after wet forming processes before the green bodies can be debonded. It is time-consuming, energy-intensive and costly. The drying behavior of the green bodies is recorded in-situ using a precise underfloor scale and a climate-controlled measuring chamber. The flexible temperature control between room temperature and 130 °C as well as the variably adjustable flow rate of up to 10 m/s (1,440 m³/h) allow the simulation of drying processes close to industrial conditions. The chamber volume is 200 x 200 x 458 mm³, the maximum sample weight is 1 kg.

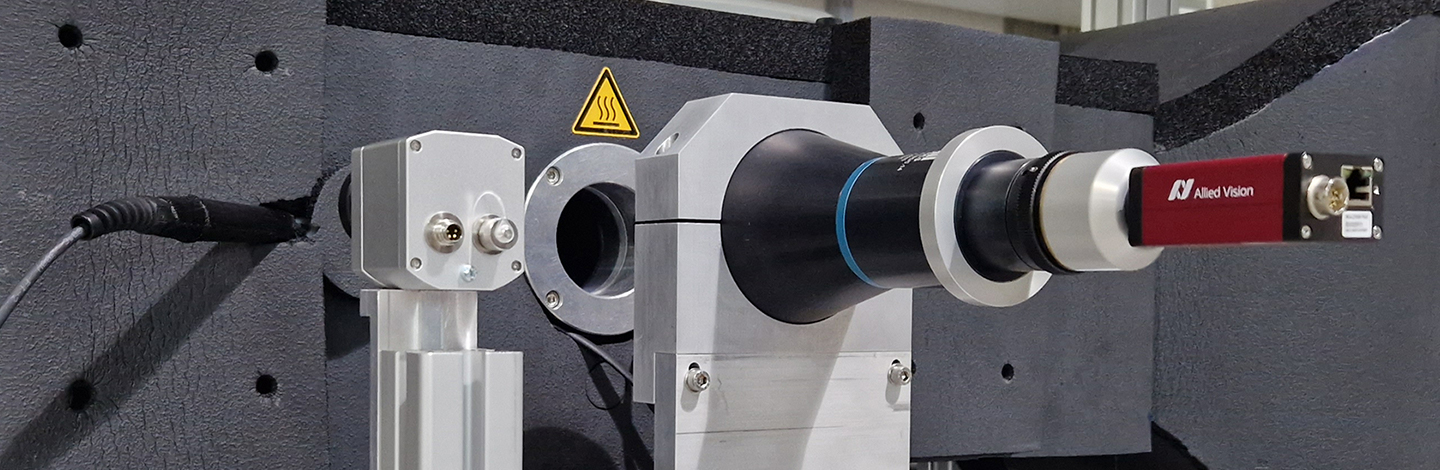

The optical evaluation can be carried out with visible light (shadow casting) or by means of an infrared camera. While the shadow casting is used to measure the dimensional change, the surface temperature can also be determined locally with the IR camera.

Using a special drying scale, component weight, flow velocity, humidity and temperature can also be measured directly in industrial drying units. The weighing range can be varied between 1 kg and 100 kg.

The measured data - together with other material data such as green strength, viscoelastic material moduli and permeability - are used in special FE models for drying in order to optimize the drying conditions.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth