Fraunhofer Center HTL advises customers on the selection of the optimal materials for a planned product or manufacturing process. In addition to the composition, the material structure is also taken into account. The material requirements are derived from computational deployment analyses on the planned component if they are not already known. Process requirements and cost aspects are also considered in material selection. Depending on the needs, studies, simulations, or model experiments are conducted.

Material Selection

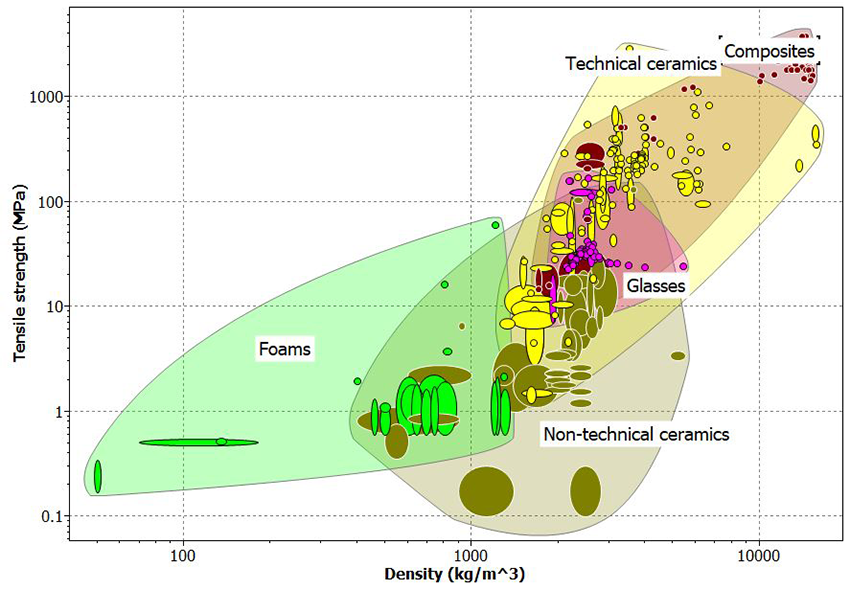

For complex requirements, material indices (see Raether, F.: Ceramics Facing Competition with other Materials, Ceramic Applications, 4/2016) are used to make an optimal material selection from the available materials. Their material properties are taken from special databases. If material data - particularly at high operating temperatures - are not available in sufficient quality, they can be measured at the HTL.

The stability of the selected materials in use or during manufacturing can be investigated using thermodynamic methods. The HTL has powerful databases (FACTSAGE) and many years of expertise for this purpose. Special AI algorithms are developed to supplement missing data. In addition, model experiments can also be carried out for this purpose.

The potential of multiphase ceramics can be significantly expanded through a microstructure design. The HTL has validated methods for predicting the material properties of ceramics - even with a complicated microstructure. It develops so-called top-down procedures with which the optimal composition and preferred structure of the ceramic can be derived from the required material properties. If required, user apps can be developed with which ceramic manufacturers can perform this top-down design for a specific system themselves. Corresponding ceramics can also be produced at the HTL upon customer request (see Ceramics/CMCs).

Service Offering:

- Advice to customers on the targeted selection of materials

- Conducting database and literature research

- Material selection using material indices

- Measurement of material properties

- Analysis of thermodynamic stability

- Conducting model experiments

- Material design of ceramic materials

- Development of user apps for the design of multiphase ceramics

Further Publication:

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth