Currently Funded Projects

Motivation

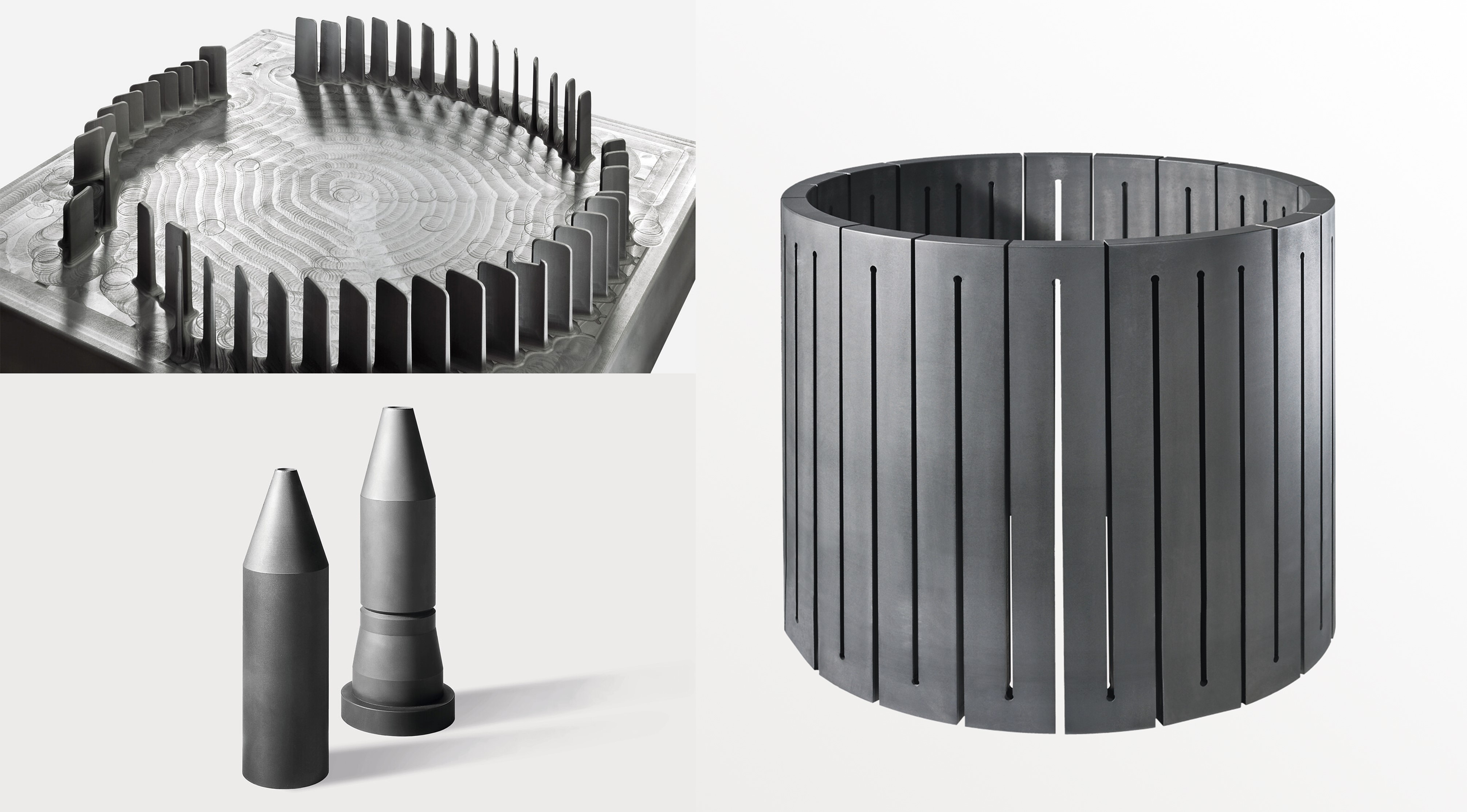

Nowadays, high-quality synthetic graphite is required for a whole range of applications, including semiconductor production (substrates, crucibles), industrial furnace construction (graphite felts and heaters), glass and quartz production (molds, tools, etc.), for electrical abrasives and brushes, electrodes for electric steel production and aluminum electrolysis or in metal casting (molds, crucibles, etc.).glass and quartz production (molds, tools, etc.), for electrical grinding pieces and brushes, electrodes for electric steel production and aluminum electrolysis or in metal casting (molds, crucibles). Graphitization processes require temperatures of up to 3,000 °C and are therefore very energy-intensive. Targeted optimization of energy and material efficiency has so far only been possible to a limited extent because the high temperatures can only be monitored indirectly and therefore imprecisely, and because no measurement methods are yet available for determining the degree of graphitization in situ.

Objectives

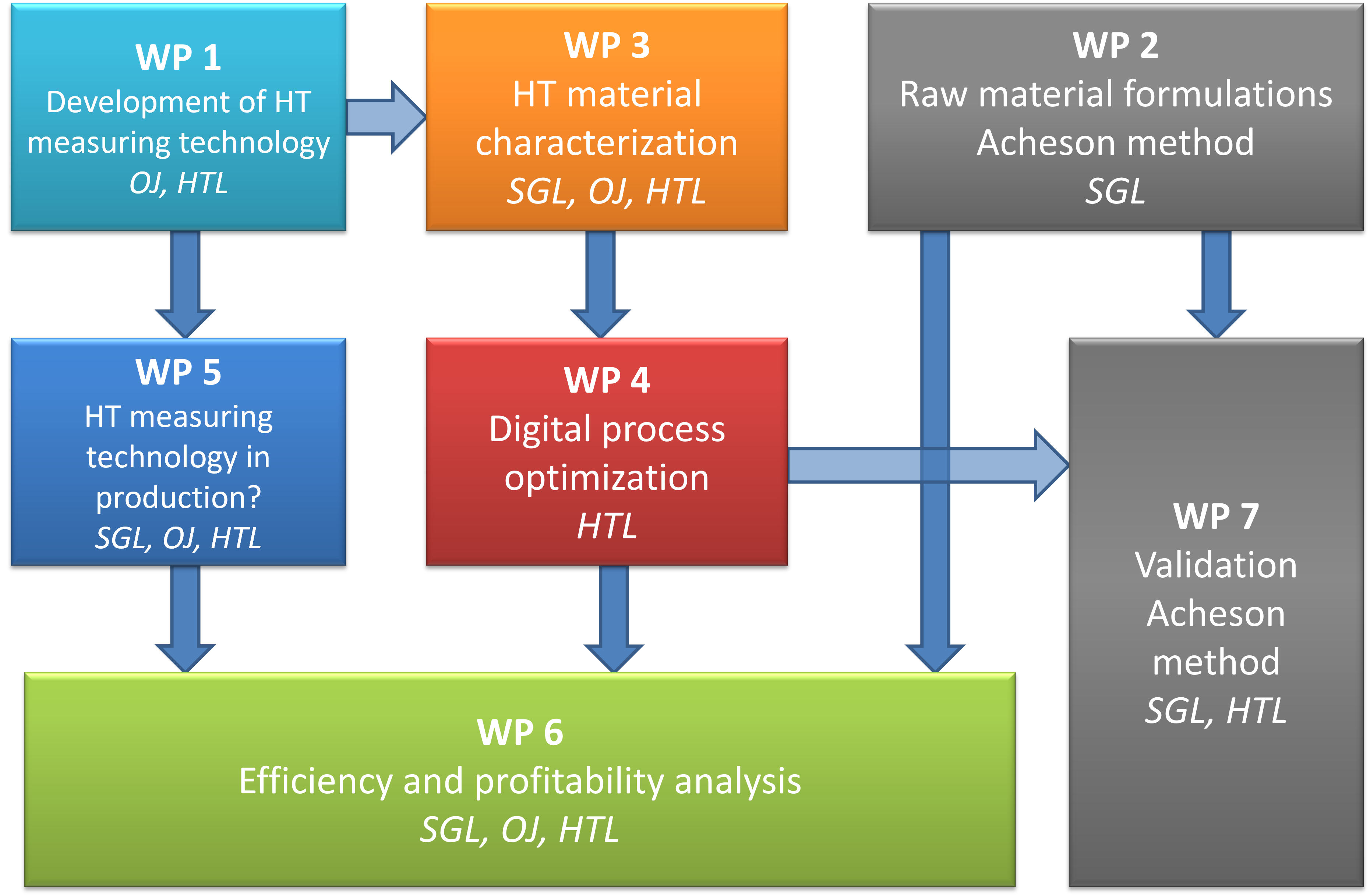

The overall aim of the project is to develop innovative ultra-high temperature measurement methods and use them to optimize two different graphite production processes in terms of energy and material efficiency:

(1) the classic Acheson process,

(2) a continuous process for powder graphitization

At the end of the project, the energy-saving potential in the production of synthetic graphite will be demonstrated in combination with the methods developed.

Approach

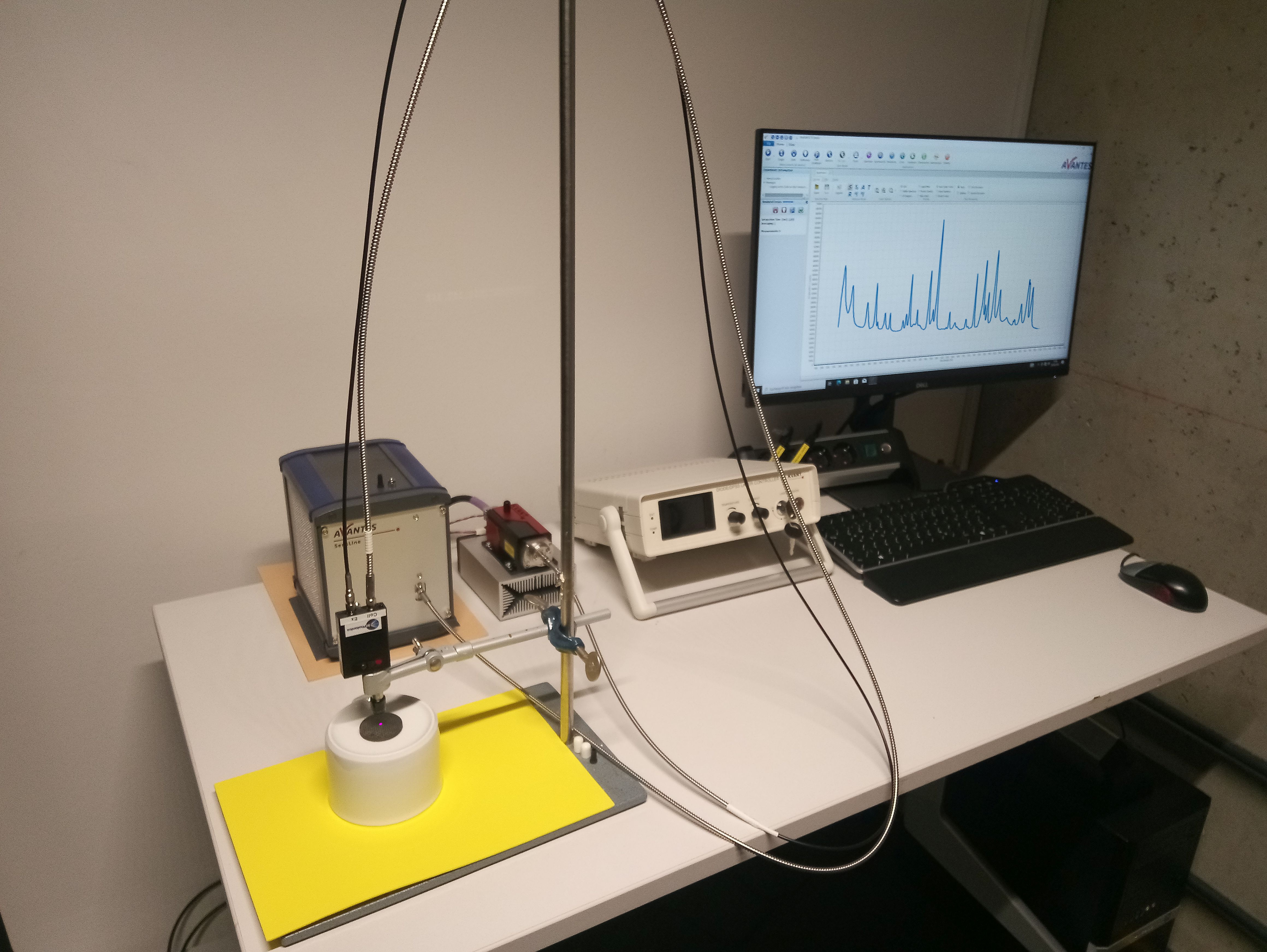

- Development of new high-temperature measurement methods for in-situ characterization of graphite quality during heat treatment

- Development and testing of the methods and algorithms under laboratory conditions

- Construction of an ultra-high temperature laboratory furnace (TOM_UHT)

- Qualification and validation on an industrial scale

- Qualification and improvement of existing measurement methods for process characterization (pyrometry, temperature measuring lances)

- Development of digital process twins for both graphitization routes

- Optimization of process conditions with regard to minimum energy consumption with the help of digital twins

Project Data

| Project Duration | 01.06.2024 - 31.05.2028 |

| Sponsor | Federal Ministry for Economic Affairs and Climate Action (FKZ 03EN2114A) |

| Funding Amount HTL | 460,000 Euro |

| Project partner | SGL Carbon, Onejoon GmbH |

| Project coordination | Fraunhofer Center for High Temperature Materials and Design (PD Dr. Gerhard Seifert) |

| Project management at HTL | Dr. Kirsten Schulze |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth