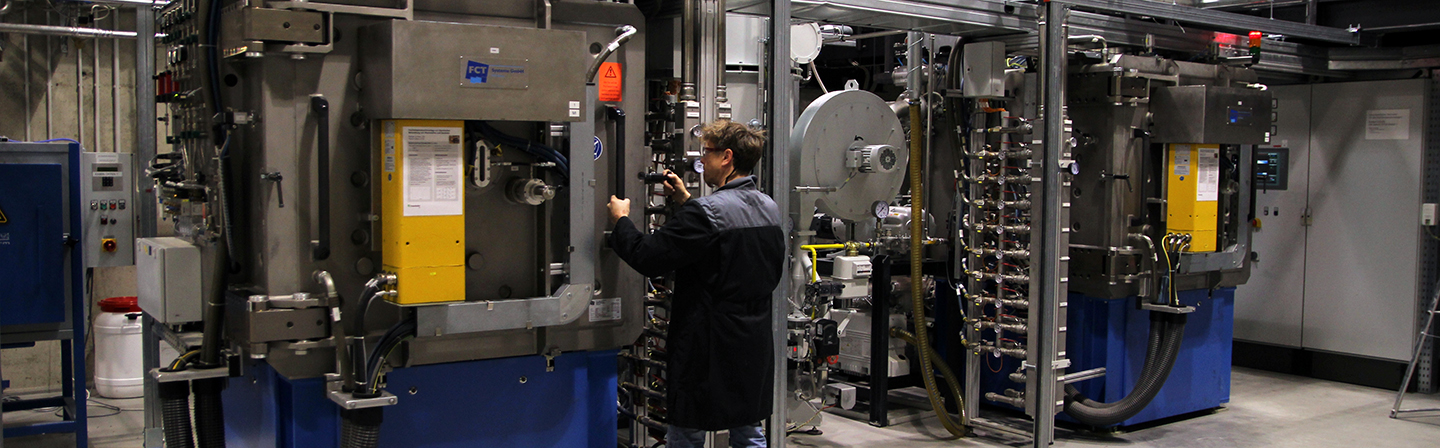

At Fraunhofer Center HTL, numerous furnaces are available for the thermal treatment of oxide and non-oxide ceramics and metals. The following processes can be carried out in different atmospheres and optimized in close collaboration with the customer: debinding, pyrolysis, graphitization, melt infiltration (especially with silicon), and sintering. Various systems are connected to thermal afterburning, so that processes that generate large amounts of condensate can also be carried out. In addition to test firings, all samples and components can be subjected to quality control before and after firing through mechanical and non-destructive material testing, density measurements, etc., in order to document any material changes or damage to the components.

Contract Firing Processes

Service Offering:

- Execution of test and contract firings according to customer specifications in defined atmospheres such as vacuum, normal or overpressure, inert gas or hydrogen up to a maximum of 2400 °C or in gas burner atmosphere or air up to a maximum of 1800°C.

- Furnace usage volume up to 385 liters, suitable for the production of large individual components or small series

- Maximum component size up to 800x800x600 mm³ can be processed

- Optimization of thermal treatment processes such as debinding, sintering, graphitization, and melt infiltration

- Process control and process safety through PLC control, optical monitoring, and measurement of the composition of furnace atmosphere

- Process documentation and final inspection of components according to customer requirements

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth