Currently Funded Project

Motivation

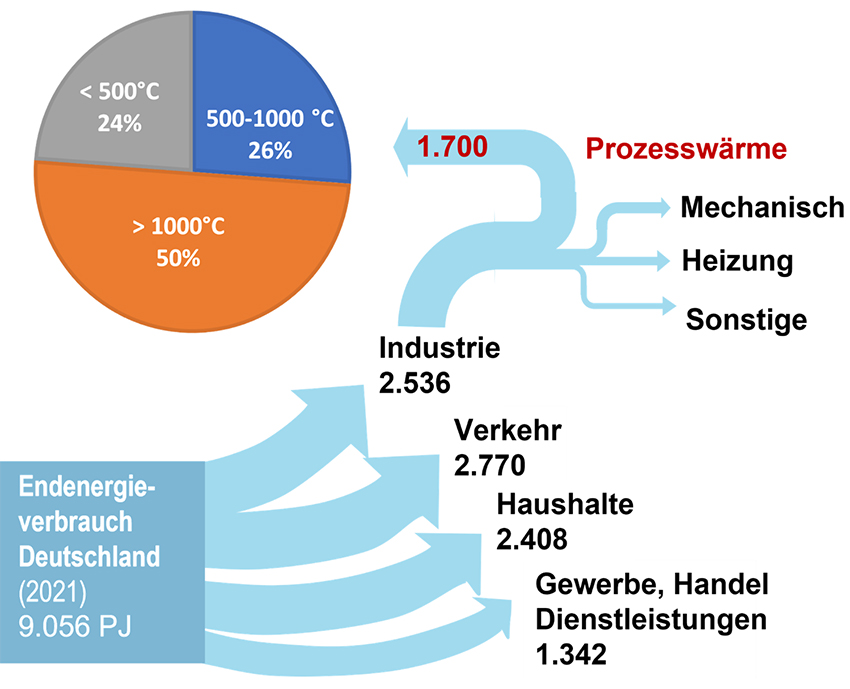

- Heat treatment processes that take place at temperatures > 1,000°C are responsible for almost half of the energy consumption in the manufacturing sector.

- The energy efficiency of thermal processes is largely determined by the refractory materials used. A rough guide is 20% of the total energy.

- Refractory materials are used as kiln insulation and thus determine the heat losses to the environment. They also serve as kiln furniture (BHM) when positioning the material to be heated in the kiln. Refractory materials are under extreme price pressure.

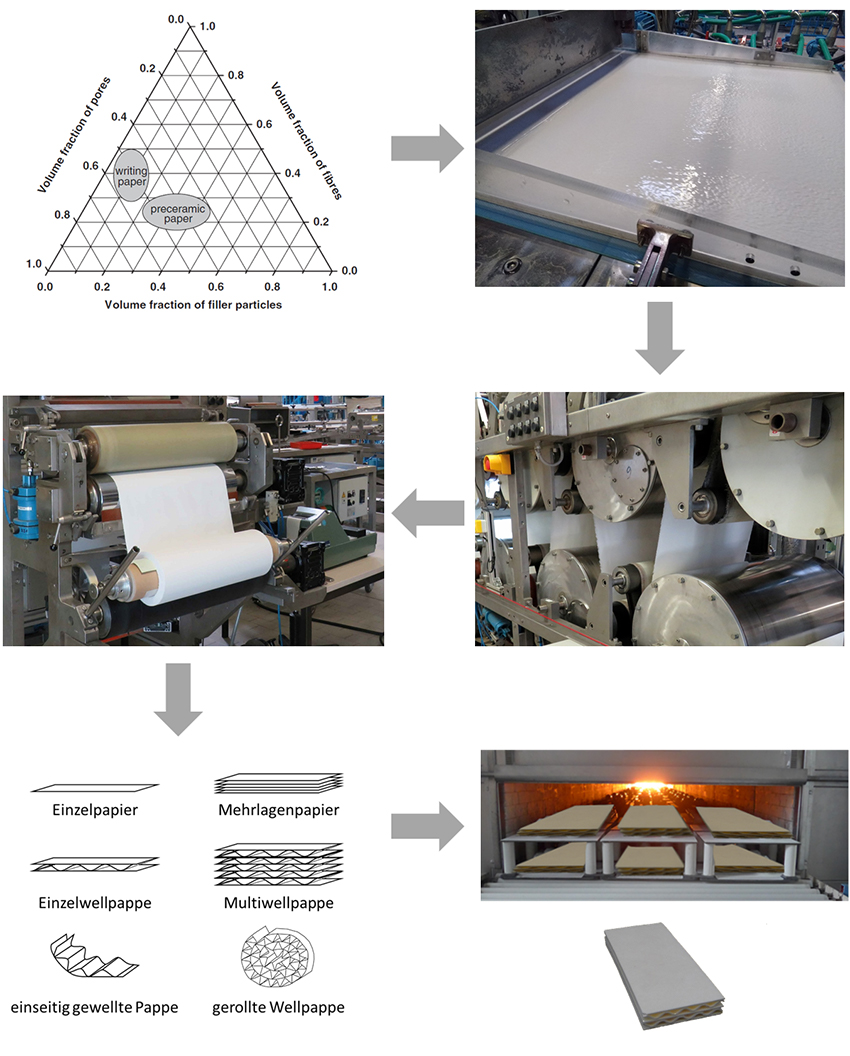

- Lightweight, topology-optimized ceramics with defined microstructures would enable enormous energy savings.

- Paper technology manufacturing processes combined with corrugated board production methods enable significant cost reductions due to the higher throughput.

- Despite successful feasibility studies, industrial implementation of paper-ceramic furnace components has not yet been achieved.

Objectives

- Development of paper-ceramic radiation shields to reduce wall losses in oxide kilns.

- Development of paper-ceramic sheet support structures as kiln furniture (BHM).

- Reduction of BHM weight by 60% while maintaining strength, creep resistance and thermocycling properties.

- Annual fuel savings in Germany of 50% (approx. 3 PJ resp.) <-> Reduction of greenhouse gas emissions of 165 kt CO2eq.

- Fabrication of one demonstrator each for radiant screens and kiln furniture (BHM).

- Test the demonstrators in industrial use and record the energy savings.

- Preparation of the industrial feasibility and determination of the adaptation needs of the plants for paper and corrugated board production.

- Testing of the manufacturing processes up to pilot scale.

Approach

- Determination of suitable raw materials and particle size distributions using computer-aided processes and databases

- Development and use of efficient low-e-coatings

- Design of microstructure and support structure geometry for ceramics produced using paper technology by means of microstructure simulation and topology optimization

- Optimization of efficient thermal processes (debinding and sintering) and their transfer to industrial furnaces

| Project Duration | 1.2.2023 - 31.1.2026 |

| Sponsoring | Bundesministerium für Bildung und Forschung |

| Funding Amount HTL | 540.000 Euro |

| Project Partners | Paul Rauschert GmbH & Co. KG OecoPac Grunert Verpackungen GmbH Voith GmbH & Co. KGaA BHS Corrugated Maschinen- und Anlagenbau GmbH Friedrich-Alexander-Universität (FAU), Institut für Werkstoffwissenschaften WW3 Papiertechnische Stiftung (PTS) |

| Project Coordination | Fraunhofer Center for High Temperature Materials and Design HTL |

| Project Management at the HTL | Dr. Holger Friedrich |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth