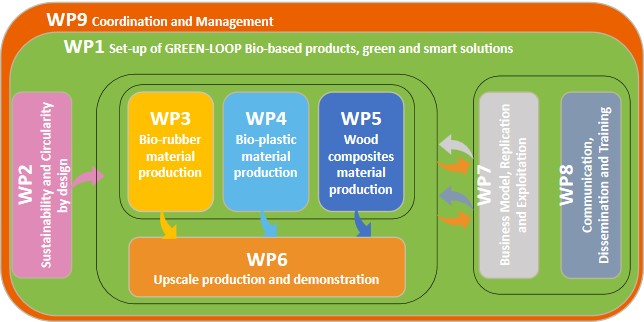

Currently Funded Project

Motivation

Global consumption of biomass, fossil fuels, metals and minerals is set to double over the next 40 years. At the same time, the annual quantity of waste will increase by 70 % by 2050. This creates the need to develop high-quality products and services that are sustainable and produced using renewable materials. Climate neutrality is to be achieved through a circular economy. Newly developed technologies should help to boost the efficiency of processes and conserve energy during production.

Objectives

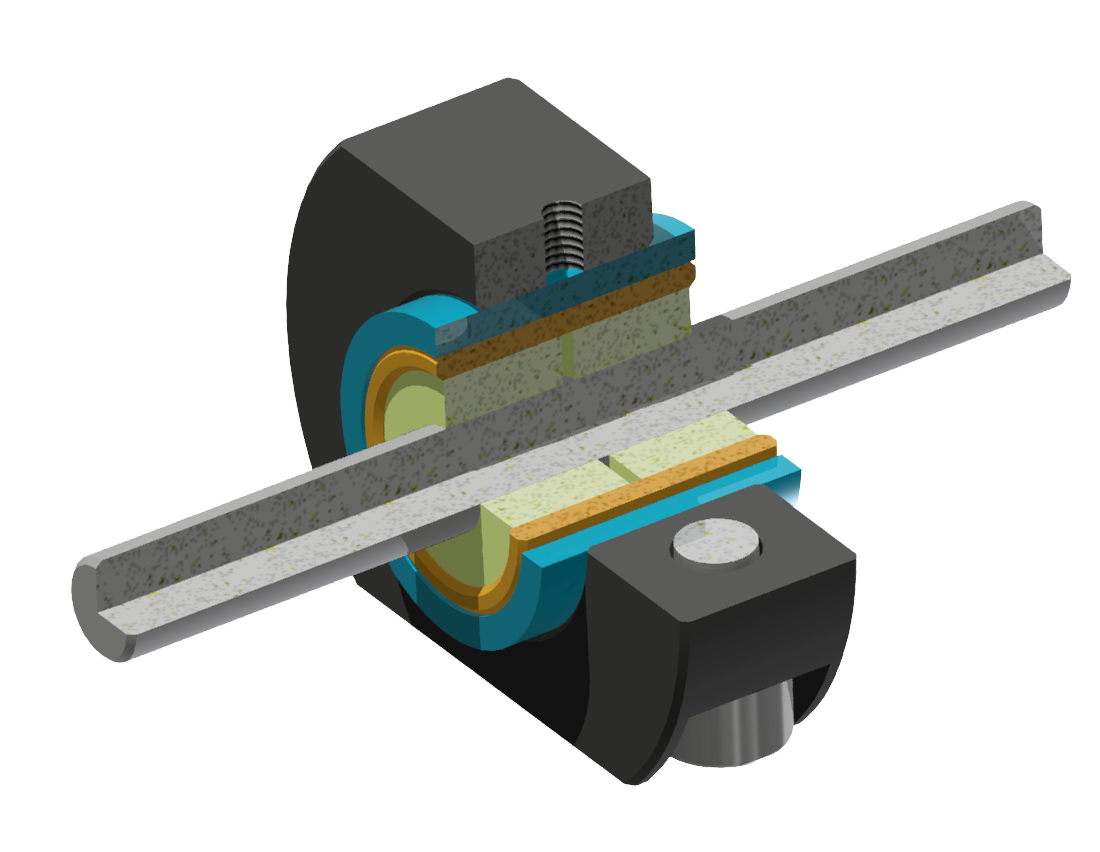

The primary objective is the production of sustainable bio-based composites in closed and cost-efficient process cycles, substituting conventional materials. Only natural raw materials will be used for the development. The manufactured products will be recyclable. At the HTL, a so-called Wood Composite (WC) material for sliding bearings is to be developed, which is sufficiently pressure-resistant and has a coefficient of friction < 0.3 and a wear coefficient of approx. 10-4 mm³/(Nm).

Approach

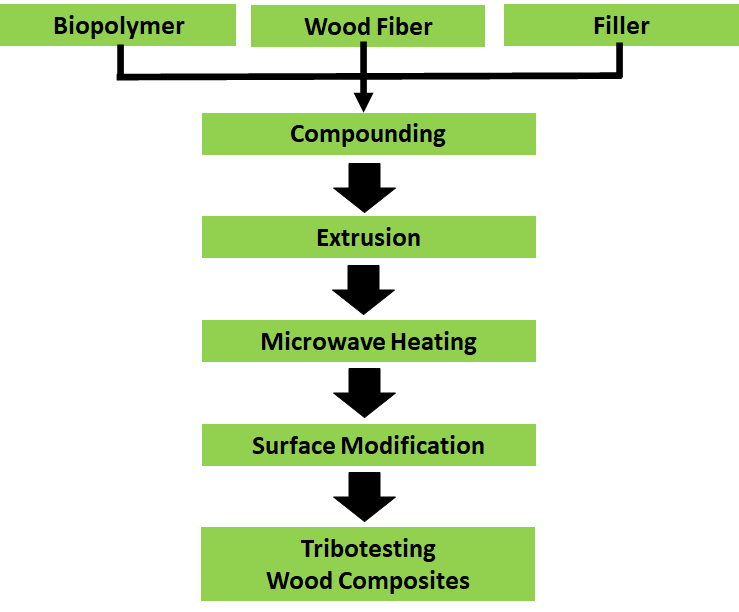

At the HTL, experimental samples and prototype components for tribological testing at Fraunhofer IWM and LABRENTA will be manufactured by the extrusion of compounds.

- Selection and examination of biopolymers, wood fibers and tribologically effective additives

- Development and commissioning of an extruder with innovative microwave curing and sensor technology for process monitoring

- Processing of newly developed compounds to WC by extrusion and process optimization

- Optimization of properties for sliding bearing applications by variation of additives

- Examination of the recyclability of the developed WCs

Project Data

| Project Duration | 1.9.2022 - 31.8.2025 |

| Sponsoring |

HORIZON-CL4-2021-TWIN-TRANSITION-01-05 |

| Funding Amount HTL | 300.000 Euro |

| Project Partners | IDENER Research & Development, National Composite Centre, National Institute of Chemistry, University of Bristol, Slovenian National Building and Civil E.I., Fraunhofer Gesellschaft zur Förderung der Angewandten Forschung, LABRENTA SRL, Mixcycling SRL, NERO SU BIANCO, Gerace Maria Cristina - Terre di Zoè, IRIS Technology Solutions - Sociedad Limitada, Główny Instytut Górnictwa, Aachen University: Process Control Engineering, Aachen University: Institute of Sociology, Austrian Standards International, Instituto de Soldadura e Qualidade, AXIA Innoverion UG, Asociación de Investigación Metalúrgica del Noroeste |

| Project Coordination | IDENER Research & Development |

| Project Management at the HTL | Dr. Jens Schmidt |

Click here for the project website GREEN-LOOP.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth