The characterization of ceramic and metallic materials at high temperatures is one of the research focuses at Fraunhofer Center HTL. Commercially available equipment for thermal characterization and analysis, as well as specially developed measuring furnaces for determining specific properties, are available. Commercial thermal analysis equipment is used to measure weight loss, heat capacity, heat of reaction, or gas emission in a controlled atmosphere (TG-DSC-MS), among others.

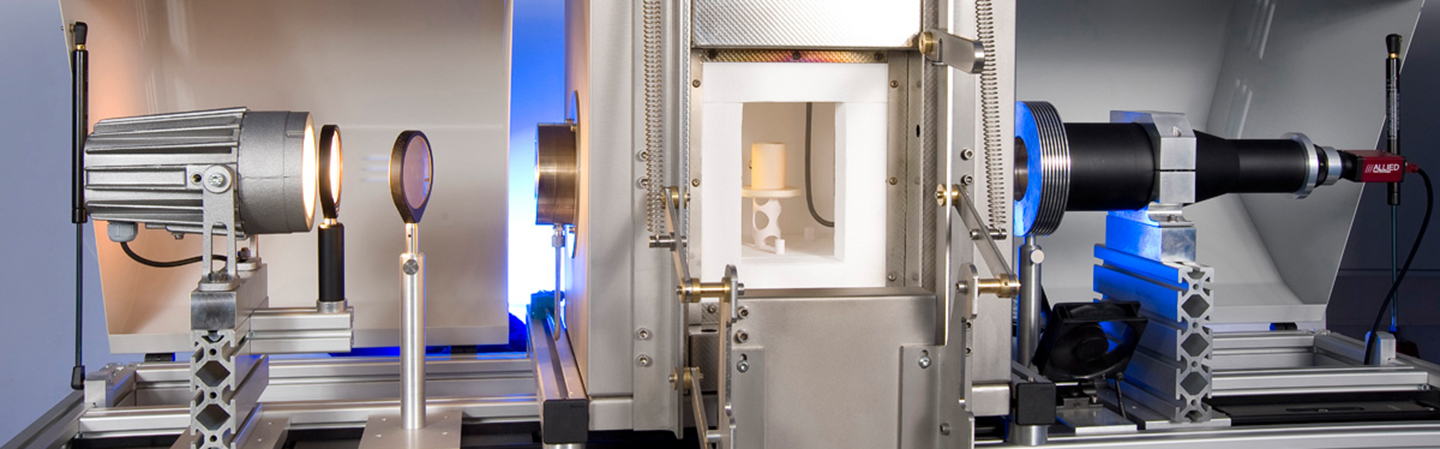

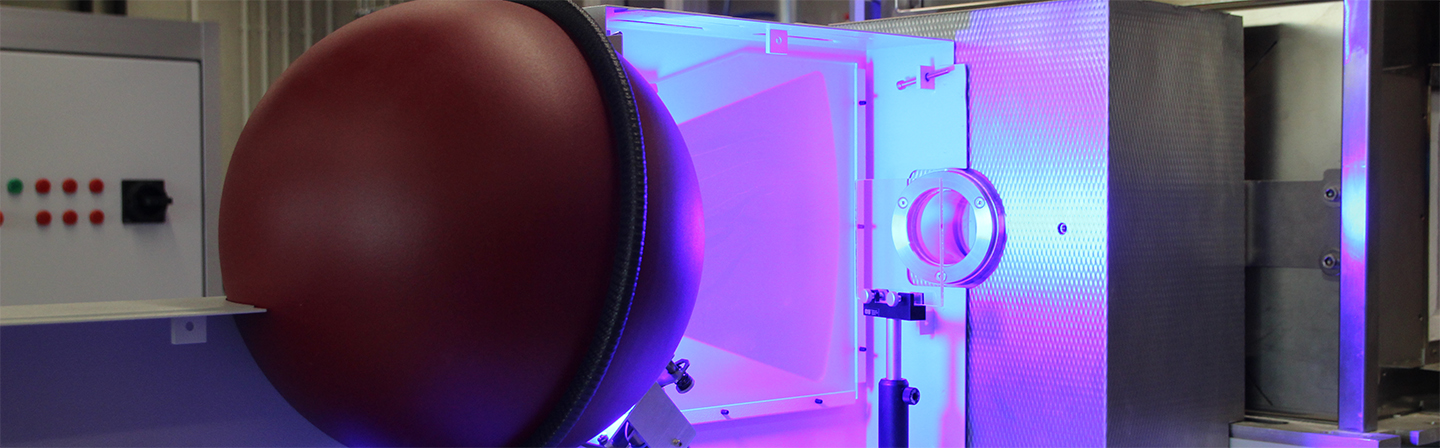

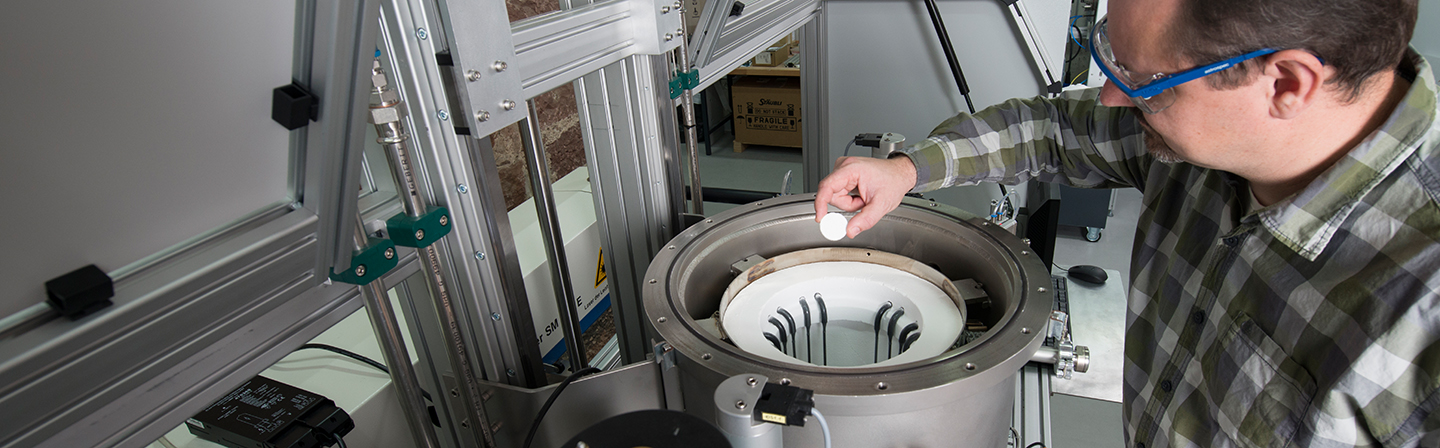

With specially developed ThermoOptical Measuring devices (TOM), industrial heat treatment processes can be replicated in the laboratory. The TOM systems can simulate all furnace atmospheres relevant in industrial furnaces: gas burner furnace atmosphere, air, inert gases, forming gas, hydrogen, vacuum, overpressure, etc. They are equipped with detectors that can accurately monitor material changes during heat treatment in situ. The dimensional changes during, for example, sintering, are measured with extremely high reproducibility or the acoustic emission signals during debinding are recorded with sensitive microphones. The characterization and analysis of high-temperature properties of materials can also be performed using the TOM systems.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth