Fraunhofer Center HTL develops solders and joining processes for high-temperature applications. The joining processes include material-material, shape, and/or force-fitting connections. They can be custom-developed for joining partners made of monolithic ceramics, fiber-reinforced ceramics (CMCs), or metals. The HTL has the entire process chain for manufacturing geometrically complex ceramic components and metal-ceramic material compounds (see Component design).

Joining Technology

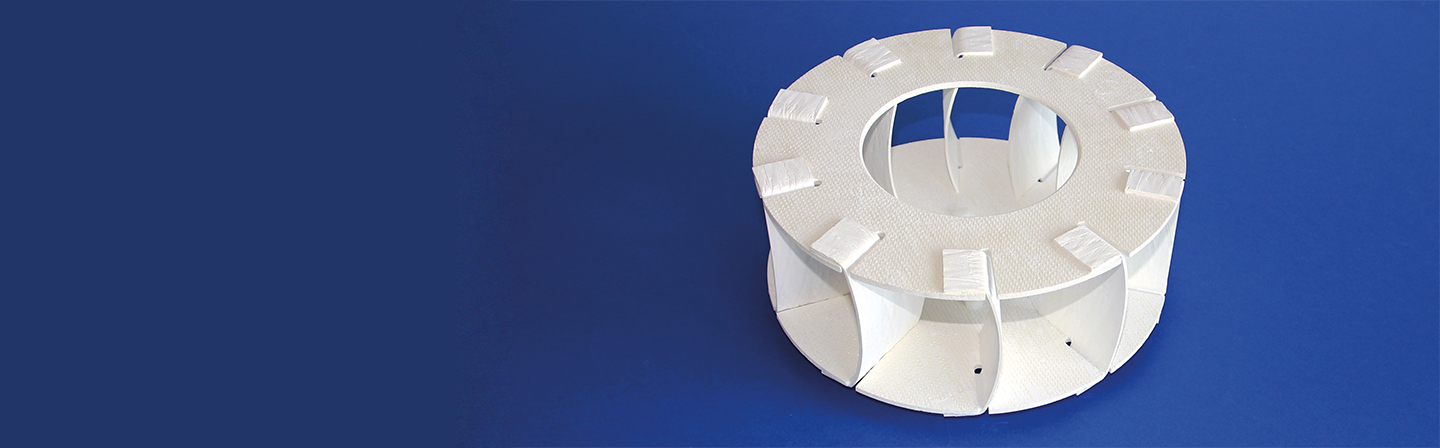

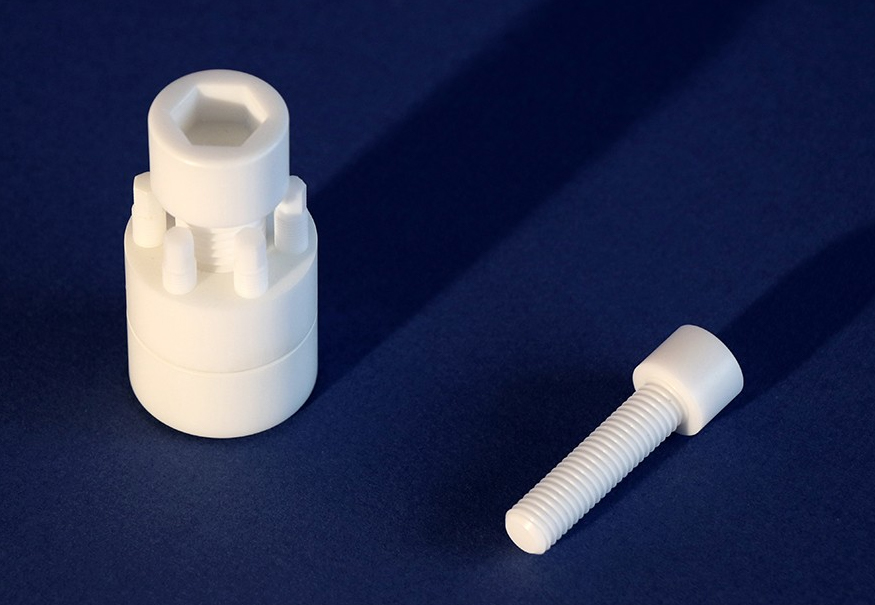

For a successful joint, the design of the components and their connection is essential. This is done at the HTL using finite element methods (FEM). By simulating the operating behavior of the respective components, the loads in the joint area are determined. The geometry of the joint is optimized to minimize mechanical and thermal stresses. The reversible combination of form and force closure is achieved at the HTL, for example, with ceramic screws (Publication: Why not Using Ceramics).

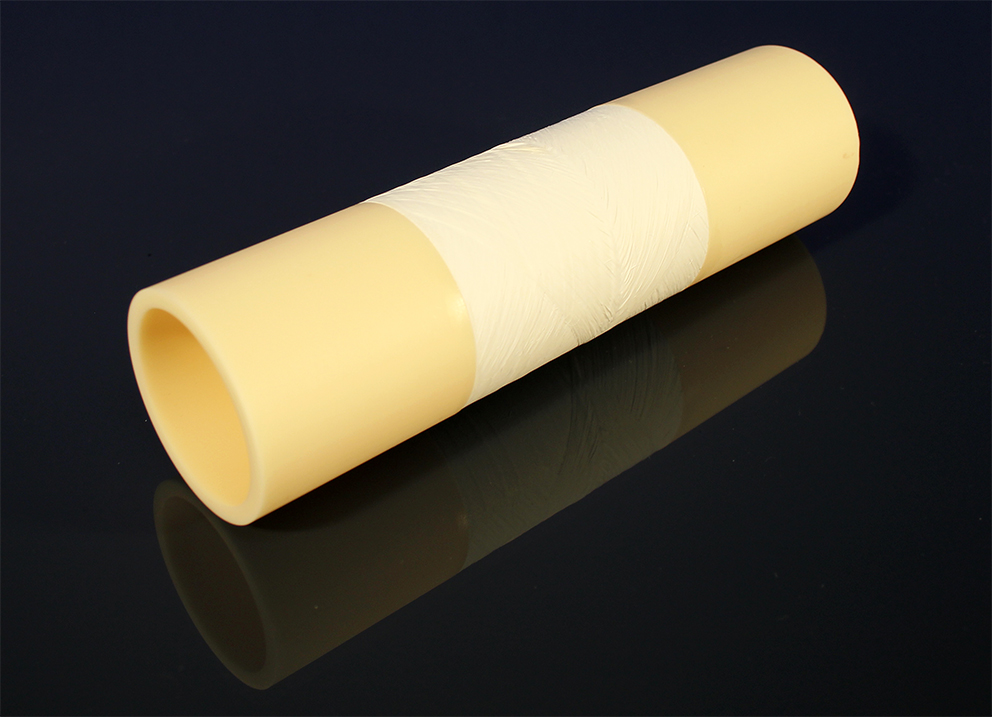

The HTL develops special crystallizing glass solders for the material-material joining process. The starting glasses have good wetting and low viscosity, allowing them to reliably fill the joint gap. For non-oxide ceramics and metals, solder based on silicon or metallic materials is also used. The solder development is supported by the thermo-optical measurement methods (TOM) available at the HTL. Different solders can be used to achieve joints between identical materials or different materials such as ceramic-CMCs, ceramic-metal or CMC-metal composites (Publication: Characterization of Furnace Sintered Mullite and Oxide Ceramic Matrix Composites (O-CMC)).

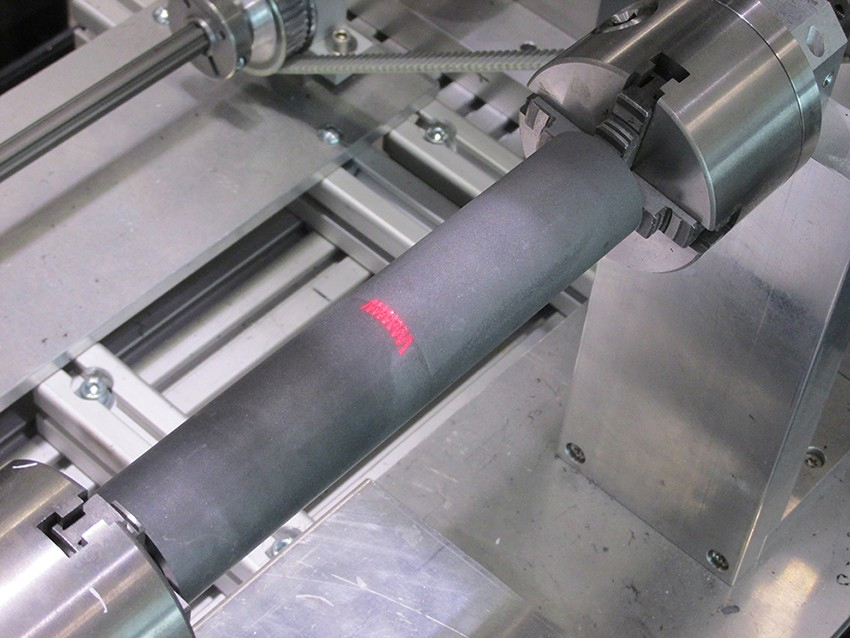

Joining processes of material composites are realized at the HTL using various systems. If low-stress heat treatment or controlled atmosphere is the main concern, conventional joining processes are carried out by furnace heating. For this purpose, the HTL has furnaces with different atmospheres and useful volumes available. The process times range from several hours to a day. Alternatively, joining can also be carried out at the HTL through laser heating at intervals of minutes (Publication: Adhesive Bonding of Ceramics).

The quality of the produced joining connections and material composites is evaluated at the HTL using various testing methods. Standard mechanical testing methods are used to determine shear and bending strengths at room temperature and high temperatures up to 1500°C. Non-destructive testing methods available at the HTL are suitable for evaluating composite components or large-area joints. To determine the tightness of joining connections, gas tightness is tested according to DIN EN 1779 at temperatures up to 1000°C at the HTL.

Service Offering:

- Feasibility studies for joining technologies

- Joining-conforming design through FE simulation

- Development of joining materials

- Construction of joining fixtures

- Development of laser joining processes

- Production of joined samples and prototypes

- Characterization of joining connections

- Gas tightness test up to 1000 °C according to DIN EN 1779

- Non-destructive testing and failure detection at joining locations

- Mechanical testing of joining connections

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth