Currently Funded Projects

Motivation

The European goal of decarbonizing its industrial sites requires feasible solutions that can be implemented in the relatively short term and scaled up to a large scale. One such solution is to replace natural gas with hydrogen as an energy source and thus reduce greenhouse gas emissions from hard-to-decarbonize industries (HTAI).

As part of the EU project H2AL, the possibilities of replacing natural gas with hydrogen (H2), reducing CO2 emissions and advancing the global fight against climate change are to be developed using the example of aluminum recycling. The development of innovative solutions will pave the way for a cleaner, greener future.

Objective

The overall aim of the H2AL project is to retrofit a range of technologies (e.g. burners, refractory material, sensors) in existing furnaces of 2A plants in such a way that foundries can be operated with up to 100% H2 for the aluminum ingot and internal scrap recycling process. The aim is to investigate the extent to which the refractory material currently used in natural gas combustion must continue to be used or be adapted accordingly in order to take account of the changed conditions in hydrogen combustion, such as increased water vapor and a higher flame speed.

Approach

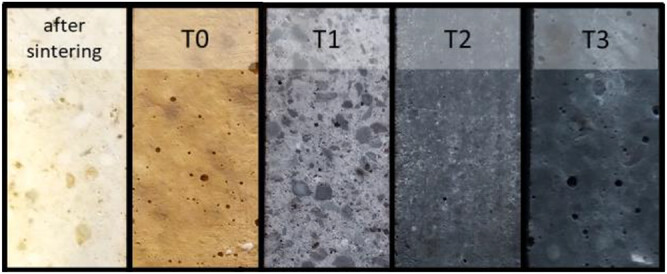

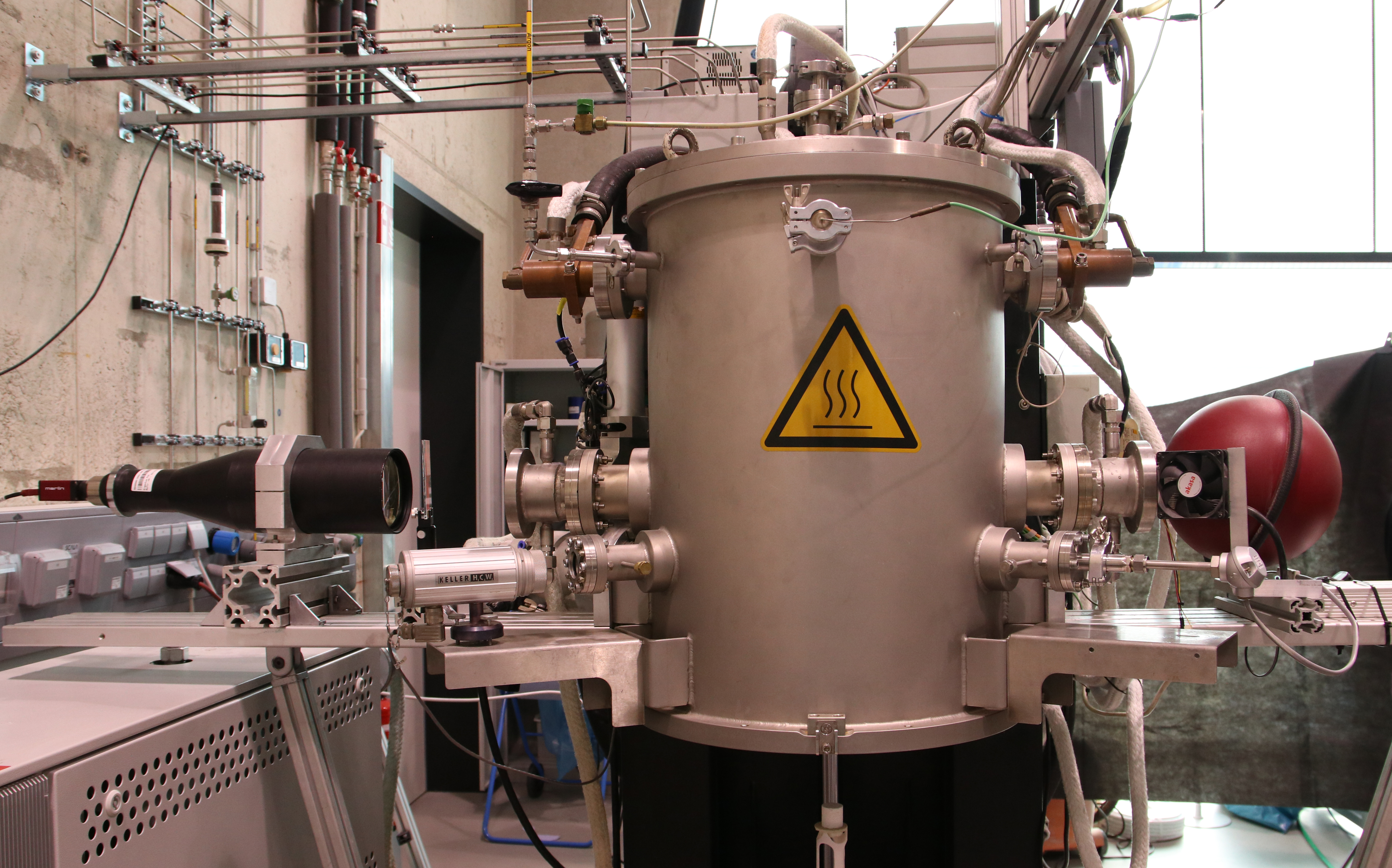

In a first step, currently used refractory materials are tested and characterized and examined for their corrosion stability against an artificial hydrogen combustion atmosphere. In addition, other state-of-the-art refractory materials with potentially better corrosion resistance will be selected based on a literature review and tested in parallel. Corrosion tests will be performed with Thermo-Optical Meters (TOM). A focus is placed on the influence of water vapor and hydrogen. In addition to material characteristics, the refractory materials are examined using SEM, CT and XRD. This will be the basis for the definition of potential new material compositions with improved performance in terms of corrosion resistance, durability and lifetime under H2 combustion conditions.

Project Data

| Project Duration | 1.1.2024 - 31.12.2027 |

| Sponsor | European Union (grant nr. 101137610) |

| Funding Amount HTL | 817,000 Euro |

| Organization |

Collaborative project (Horizion JU Innovation Actions) |

| Project Partners | Université Libre de Bruxelles, Fraunhofer-Zentrum HTL, 2A SPA, Nippon Gases Industrial SRL, Fundacion Tecnalia Research & Innovation, GHI Hornos Insustriales, Gas-Wärme-Institut Essen e.V., Bluenergy Revolution SCRL, EKW GmbH, European Aluminium |

| Project Coordination | Université Libre de Bruxelles |

| Project Management at the HTL | Dr. Alexander Konschak |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth