Completed funded project

Motivation

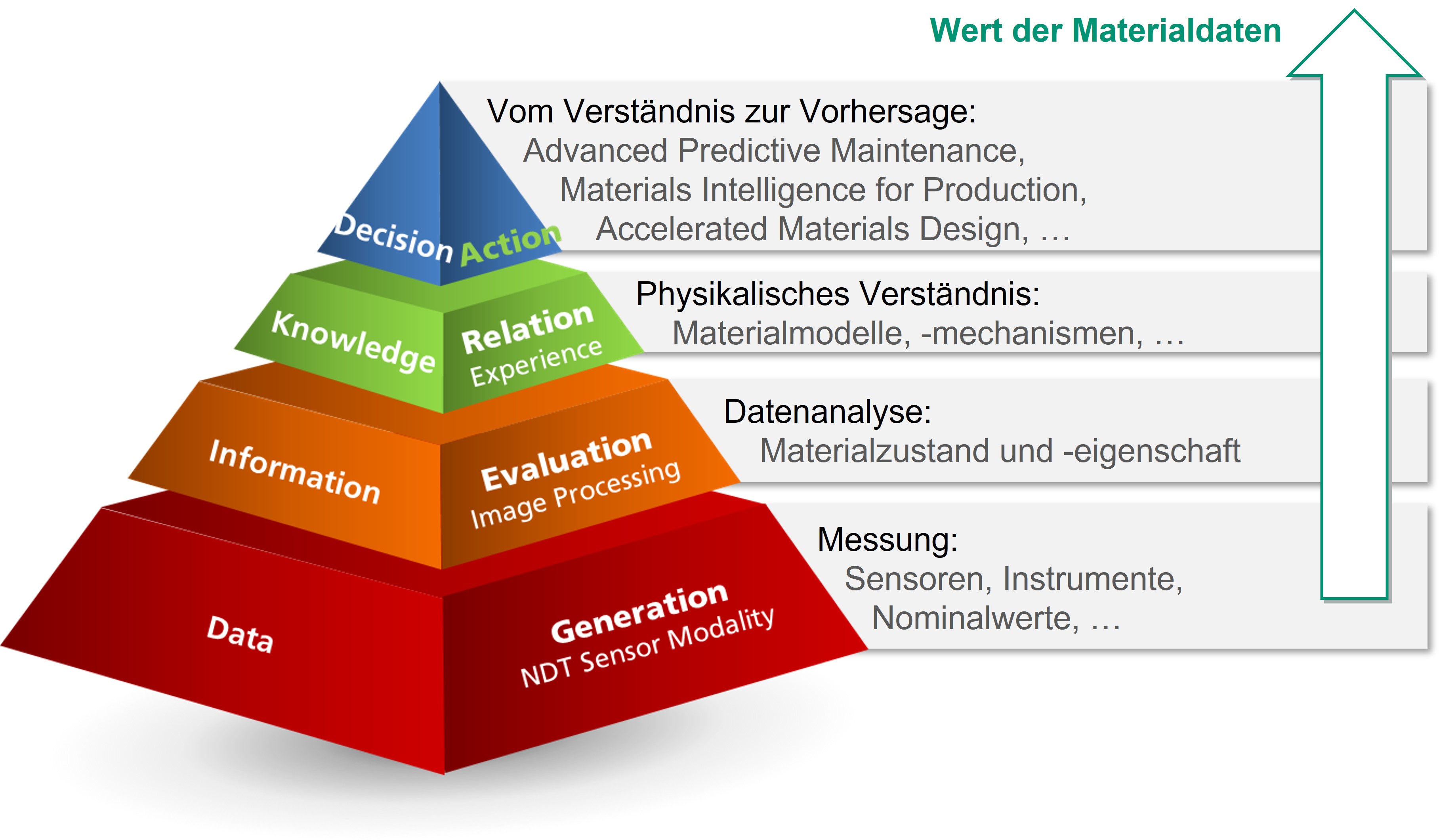

The Fraunhofer-Gesellschaft is working in cooperation with all other relevant research institutions in Germany to develop standards for the digital storage and provision of material data. This is based on the technologies already used in the Fraunhofer Materials Data Space (MDS) and the Material Digital (PMD) platform funded by the German government, in particular data storage in knowledge graphs based on material ontologies. With this concept, the measurement data can be linked with in-depth analyses and modeling through to predictions of material behaviour and used in conjunction for product and material development. The aim is to enable industry to improve the reliability, safety and functionality of its products and to adapt more quickly to market changes.

Objective

As part of the DMD4Future project, 13 Fraunhofer Institutes worked together to initially establish a uniform level of knowledge regarding the storage and processing of digital material data at all materials science-oriented institutes. In focus area 1, in which the Fraunhofer Center HTL was involved, the specific aim was to record the manufacturing chain of a cast aluminum component together with various analyses and simulations completely digitally and to store them semantically linked, as well as to develop digital tools to display the measurement and simulation data generated at different institutes in a spatially and temporally correlated manner and to be able to analyze them together.

Results

The following work was successfully carried out using the example of an aluminum casting component:

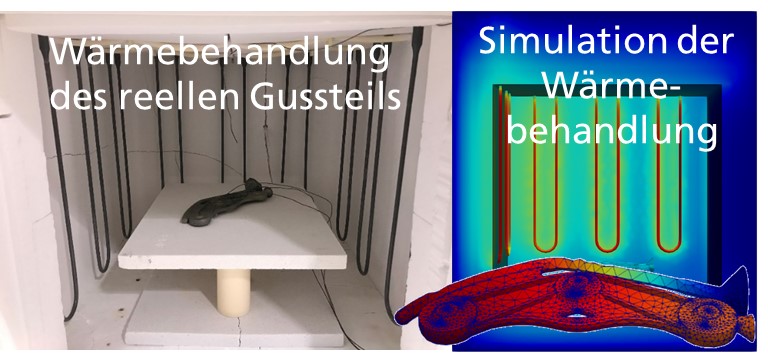

- Creation of graph databases for heat treatment (experiment and simulation) on the basis of a coordinated ontology

- Carrying out the heat treatment on real components and forwarding the components for further analysis (fatigue behavior)

- Simulation of the heat treatment in the batch furnace and provision of the simulation data for use in the graph database

- Preparation of the data for a joint 3D representation of the data generated across institutes

Projekt data

| Project Duration | 01.08.2020 - 31.12.2020 |

| Funding amount HTL | 85,000 Euro |

| Project partners | Fraunhofer EMI, IBP, ICT, IFAM, IIS, IKTS, IMWS, ISC, IWKS, IWM, IZFP und LBF |

| Project management at HTL | PD Dr. Gerhard Seifert |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth