Currently Funded Projects

Motivation

In power modules, ceramic substrates fulfill two main functions: electrical insulation and heat dissipation. Electrical insulation prevents stray currents and ensures the safe operation of high-voltage power electronics, for example in electric cars or wind turbines. At the same time, efficient heat dissipation is crucial to maintaining optimal operating temperatures for power semiconductors and preventing overheating, which could impair performance or damage components. Therefore, selecting the right ceramic material with suitable thermal conductivity and electrical insulation is critical to the reliability and efficiency of power module substrates. With the ongoing development of power electronics, particularly through the integration of wide bandgap semiconductors such as SiC chips, there is a growing demand for more precise and higher-quality ceramic substrates to ensure and optimize reliability and efficiency.

Objective

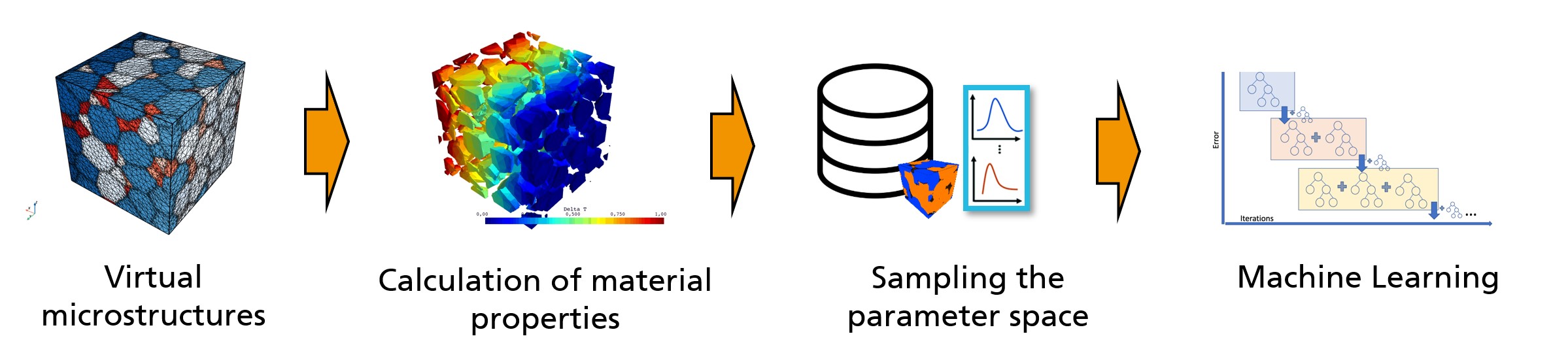

The objective is to meet the changing requirements of the power electronics industry and offer customers technical advantages as well as improved performance and reliability of power modules. Higher efficiency of power modules contributes significantly to the sustainable use of resources. The development of powerful ab initio methods for calculating crystalline phases, the availability of machine learning, and the further development of in-house methods at HTL open up completely new possibilities for digital material and process design, which will be used to achieve these ambitious goals.

Approach

- Adaptation of microstructure-property simulation

- Simulations for defining requirements for secondary phases (sintering additives)

- Screening of sintering additives

- In-situ measurements for analysis of sintering

- Determination of sintering kinetics from the measurements

- Sintering simulations for identification of favorable thermal process parameters

- Material testing

Project Data

| Project duration | 04/2025 - 03/2028 |

| Funding | Bavarian State Ministry of Economic Affairs, Regional Development, and Energy |

| Funding amount HTL | 400,000 Euro |

| Project partner and cooridnation | Rogers Corporation |

| Project management at HTL | PD Dr. Gerhard Seifert |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth