Currently Funded Project

Motivation

Silicate ceramics are used in many different ways. Areas of application include wall and floor tiles, bricks and roof tiles, stoneware pipes, sanitary products and tableware as well as high-voltage insulators. In total, more than 160,000 people work in the silicate ceramics industry in Europe. They achieve an annual turnover of around 20 billion euros.

The production of silicate ceramics is an energy-intensive industry due to the thermal processes involved. The firing process has so far been carried out almost exclusively with fossil fuels.

Objectives

TOM_dry: ThermoOptical measuring system for in-situ investigation of the drying behavior of samples under defined conditions of temperature, humidity and air flow

In line with the objectives of the 7th Energy Research Program, the project aims to achieve significant energy savings in the production of silicate ceramics. Drying plays a particularly important role.

- Development of a methodology to significantly improve energy efficiency in the manufacture of silicate ceramic products

- Demonstration of the methodology using the example of roof tiles, which have a high overall energy saving potential due to the large quantities produced

- Reduction of the energy requirement by 20%

- Ensuring the transferability of the methodology and savings to other silicate ceramics and ceramic products

- Evaluation of alternative energy sources

Approach

Sensor module for industrial drying furnaces: The module was developed in the EnerTherm project and its functionality is to be further developed as part of the SuSiDry project

- Systematic consideration of the production chain including the raw materials and the application behavior of the finished products in terms of the ICME

- Development of innovative measurement and simulation methods for the drying processes

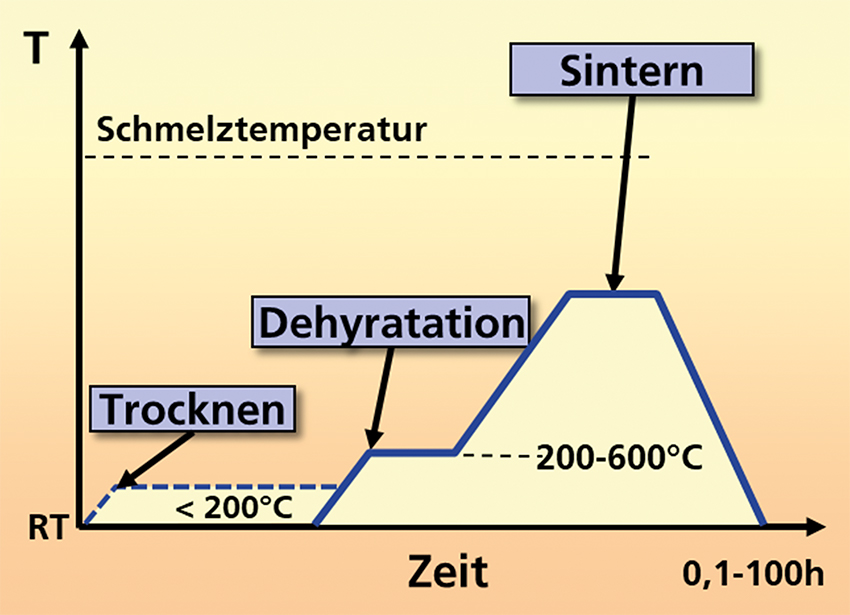

- Energetic optimization of the overall process with the models for dehydration / debinding and sintering established at the HTL

Projektdaten

| Project Duration | 1.4.2023 - 31.3.2026 |

| Sponsor |

Federal Ministry for Economic Affairs and Climate Action (BMWK) |

| Funding Amount HTL | 276,000 Euro |

| Project Partners | Fraunhofer Center HTL, Lingl Anlagenbau GmbH i. Ins., Stephan Schmidt KG, Wienerberger GmbH |

| Project Coordination | Fraunhofer Center HTL |

| Project Management at the HTL | Dr. Holger Friedrich |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth