Currently Funded Projects

Motivation

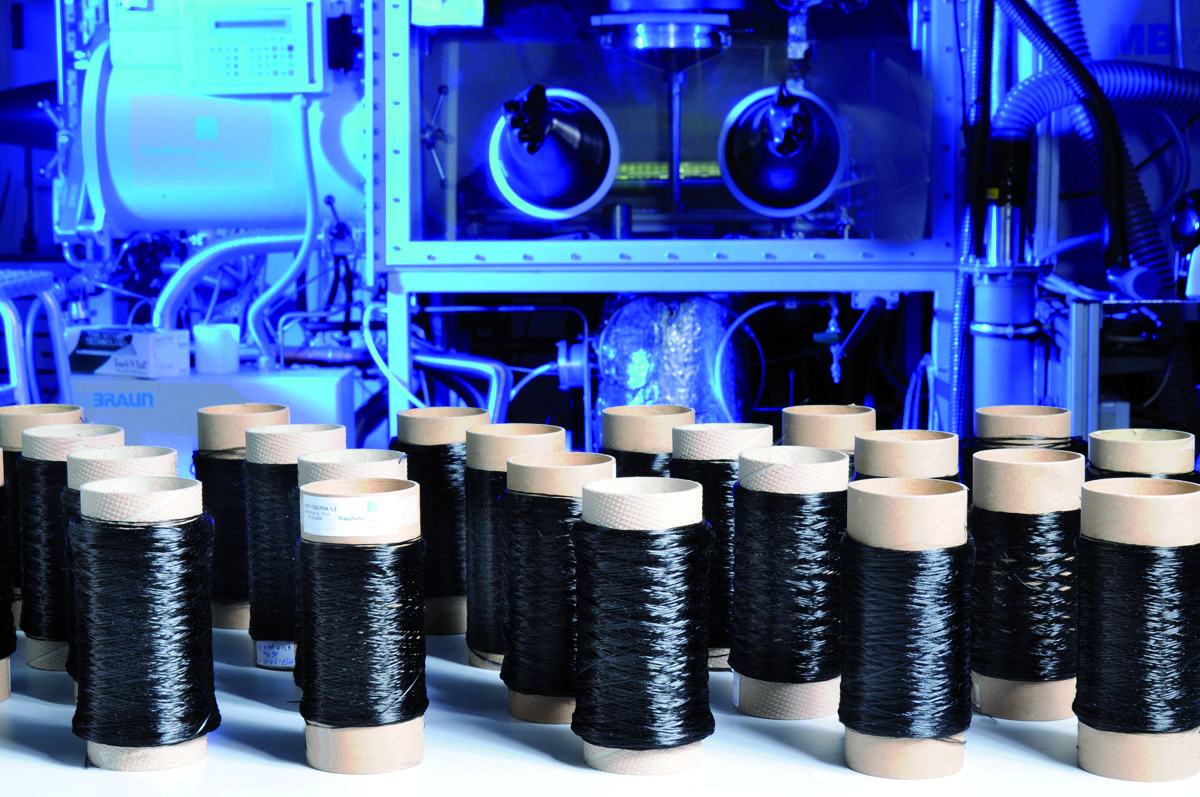

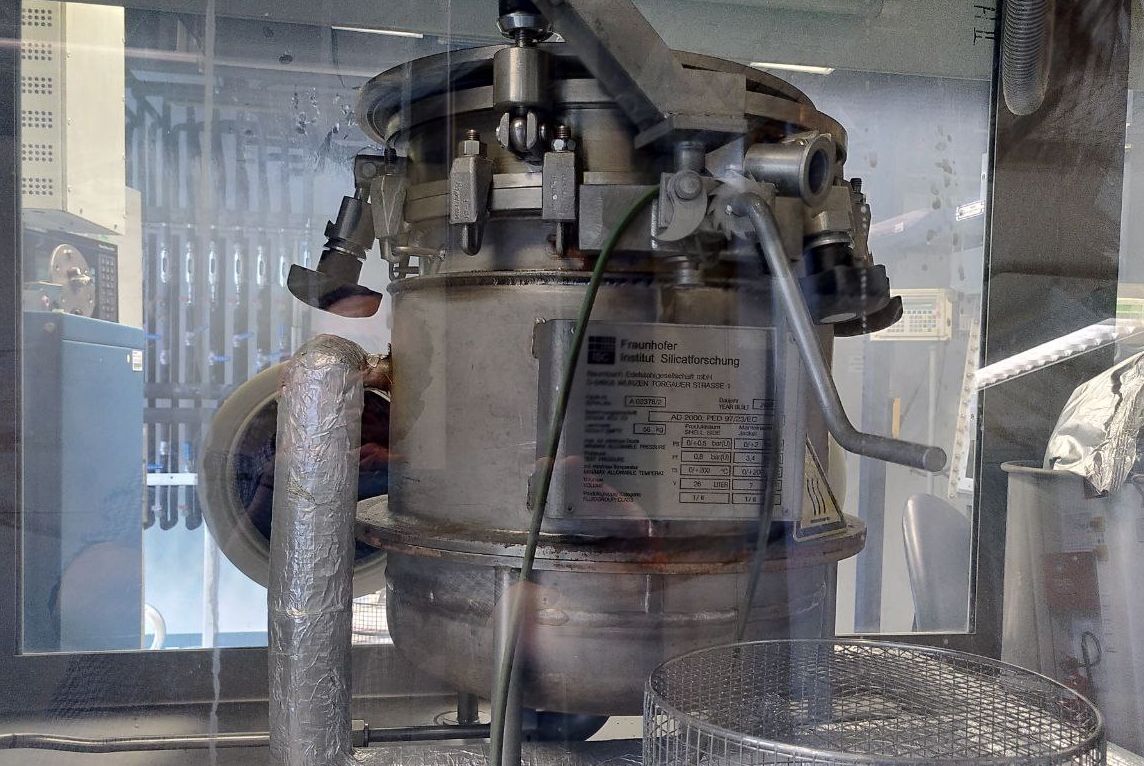

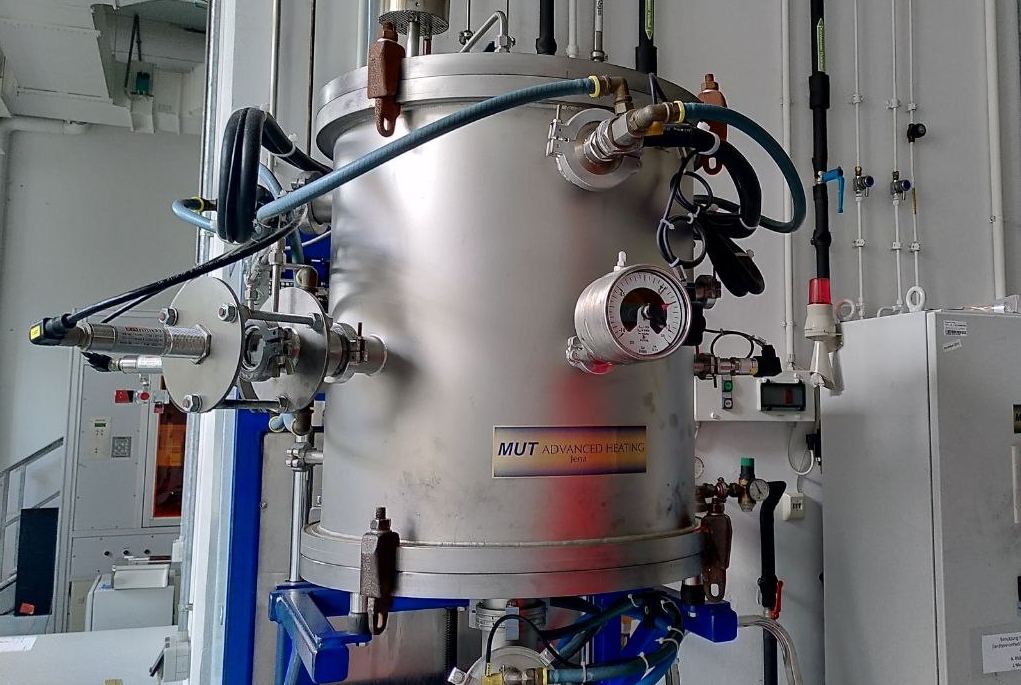

The use of SiC fibers in CMCs for aircraft engines is essential in order to achieve the emission targets set by ACARE. These components are also necessary for stationary gas turbines. European companies are at a disadvantage due to the lack of security of supply of SiC fibers, which are only produced in the USA and Asia. BJS Ceramics GmbH is closing this gap. Over the past 10 years, BJS Ceramics GmbH has developed a new process for the production of SiC fibers that uses polysilanes (PS) instead of polycarbosilanes (PCS). Since 2019, the process has been scaled up on an industrial pilot scale in the fiber pilot plant (FPA) at the Fraunhofer Center HTL in Bayreuth.

Objective

SiC fibers made at the FPA will be used to develop a high-quality material for high-tech applications that is currently lacking in Europe. These fibers are particularly important for use in demanding technological areas such as aerospace and energy generation. By developing and producing these innovative materials, Bavarian companies could take on a pioneering role and gain significant competitive advantages. The industrial implementation of this project will not only create new jobs, but also secure existing ones. SiC fibers are strategically important for the production of future aircraft gas turbines and hydrogen gas turbines, which significantly strengthens the competitiveness and value-added share of Bavarian manufacturers.

Approach

The focus of the optimization work is on curing and pyrolysis for the production of PS-based SiC fibres. These processes are crucial to ensure the desired material properties and the high quality of the fibers. The specific objectives of the project include

- Increasing throughput times while maintaining the highest fiber qualities and industry-standard reject rates

- Optimization of the curing processes

- Increasing efficiency in pyrolysis

- Maintaining the highest fiber qualities

- Increasing the degree of automation

- Introduction of automated monitoring and control systems

Project Data

| Project duration | 01.11.2023 - 31.10.2025 |

| Sponsor | Bavarian Ministry of Economic Affairs, Regional Development and Energy |

| Funding amount HTL | 200,000 Euro |

| Project partner | BJS Ceramics (project coordinator) |

| Project management at HTL | Peter Vierhaus |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth