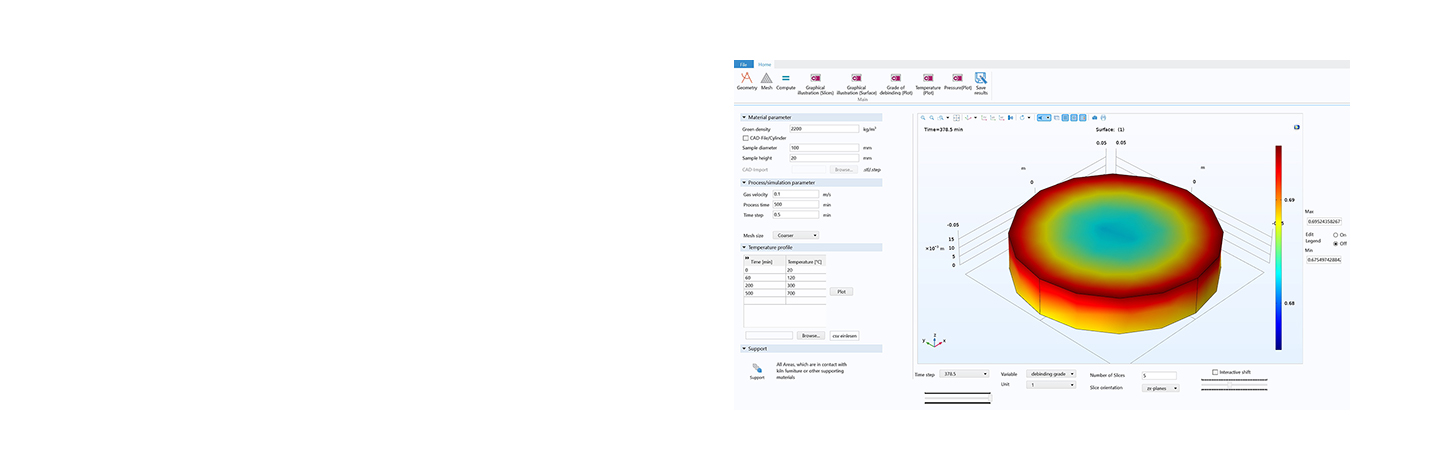

Fraunhofer Center HTL has long-established and continuously developed models for thermoprocesses that can reliably predict the behavior of ceramic and powder metallurgical green parts based on the parameters of the thermal treatment. These models have already been successfully used in many joint projects to optimize industrial processes, especially for thermal debinding and sintering. The methodology has now reached such a high level of maturity that the models can also be provided as user apps tailored to the needs of the customers.

In the area of microstructure development for multiphase ceramics, the HTL has also reached a level that enables the development of independent software tools based on microstructure-property simulations, which allow users to independently perform a top-down design of the ceramic microstructure required for specific application properties.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth