Currently funded project

Motivation

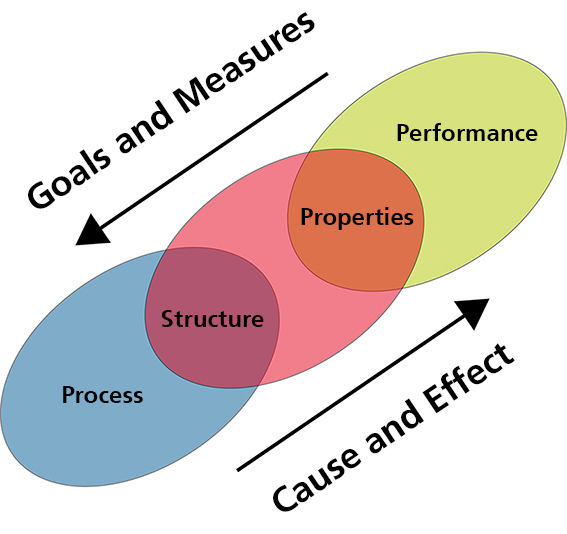

Alumina toughened Zirconia (ATZ) or Zirconia Toughened Alumina (ZTA) so-called ATZ or ZTA ceramics have the best mechanical properties within the oxide ceramics and are therefore used for numerous structural components. Their material properties (elect. and therm. properties, stiffness, fracture toughness, internal stresses) are adjusted by the mixing ratio of Al2O3 and ZrO2, the grain sizes of the two components, and the type and quantity of doping elements used to phase-stabilise the ZrO2.

In the case of ATZ/ZTA ceramics, in addition to the composition, the processing, starting with the raw material preparation, shaping, debinding and sintering up to the final machining, has a decisive influence on the material properties, especially on strength and reliability. Microstructural defects must be carefully minimised.

Objectives

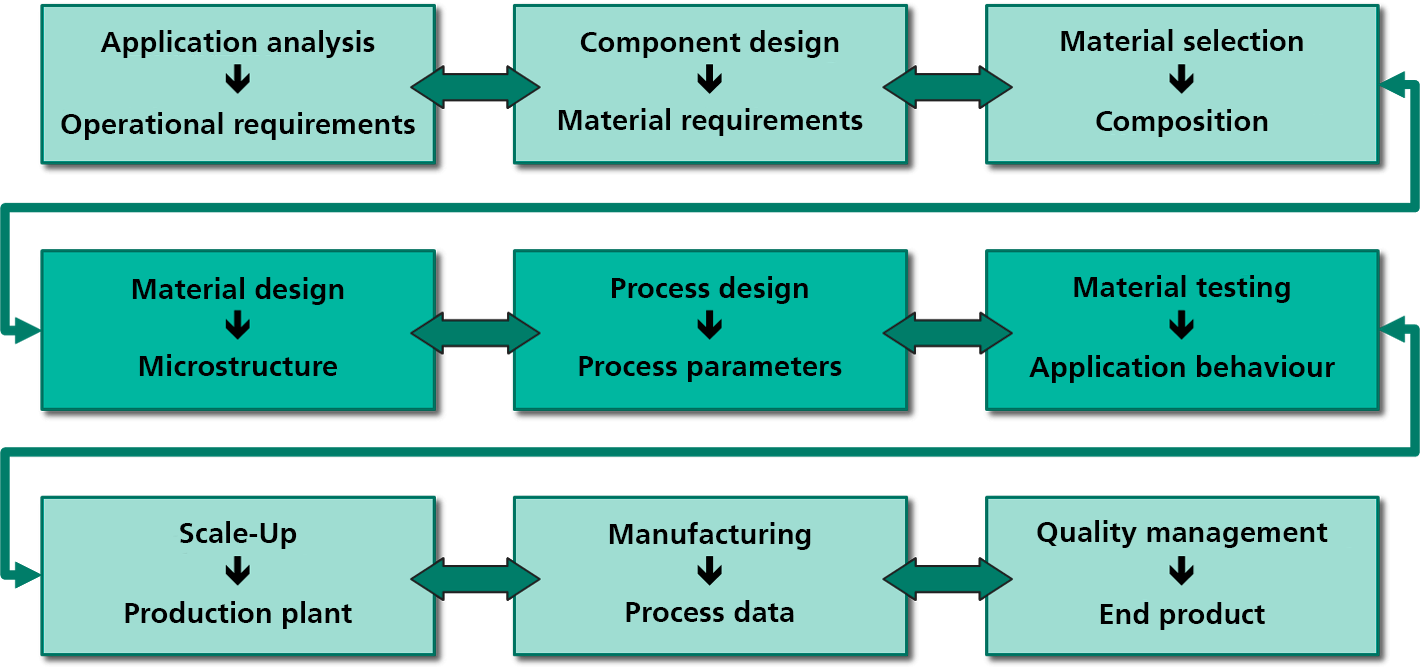

- Introduction of the ICME methodology in the development of tech. Ceramics

- Development of application-adapted AZT/ZTA ceramics

- Reduction of development times and costs along the value chain

- Improved sustainability: life cycle, material, energy consumption & rejects

- Enhanced digital competence of SMEs

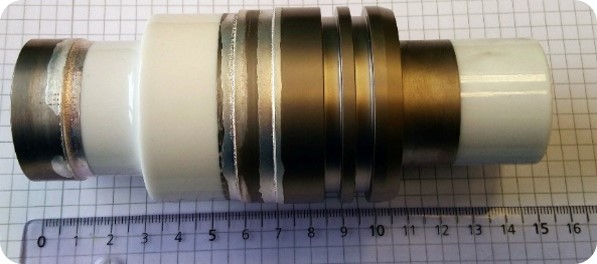

- SME-specific demonstrators

- Apps for facilitated customisation of property profiles:

Composition and thermal processes - SME internal feedstock production for more flexible property windows

Approach

- Development of ICME methods for AZT/ZTA ceramics:

Simulations and user apps for targeted material and process design and demonstrator design - Material and process development:

Raw material research, sample preparation and testing, in-situ ZrO2 doping; spec. process development: shaping & therm. processes - Characterisation of raw materials, intermediate and final products:

Density, strength, warpage, microstructure, phase analysis, fracture toughness

Project Data

| Project Duration |

01.03.2021 - 29.02.2024 |

| Sponsor |

KMU-Innovativ: Nachhaltiger Umgang mit Rohstoffen |

| Project Coordination | BCE Special Ceramics GmbH |

| Project Management at the HTL |

Marina Stepanyan |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth