Fraunhofer Center HTL optimizes thermal processes for the production of ceramics and metals with regard to energy and cost efficiency as well as product quality. Relevant processes are drying, debinding, pyrolysis, sintering, melt infiltration and various processes in the field of molten metallurgy. Potential for improvement often exist with regard to temperature-time profiles, furnace atmosphere or arrangement of the charge in the industrial furnace. The optimization goals are high and reproducible product quality with good material, energy and cost efficiency of the processes (see EnerTherm project). Both the furnace perspective and the perspective of the heated material are taken into account simultaneously.

Thermal Processes

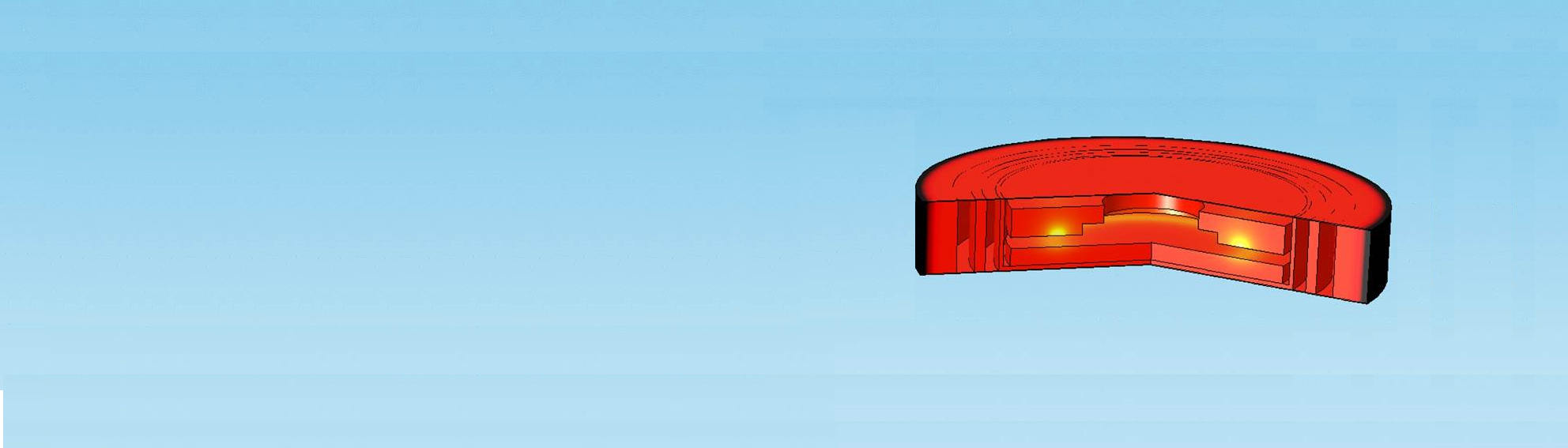

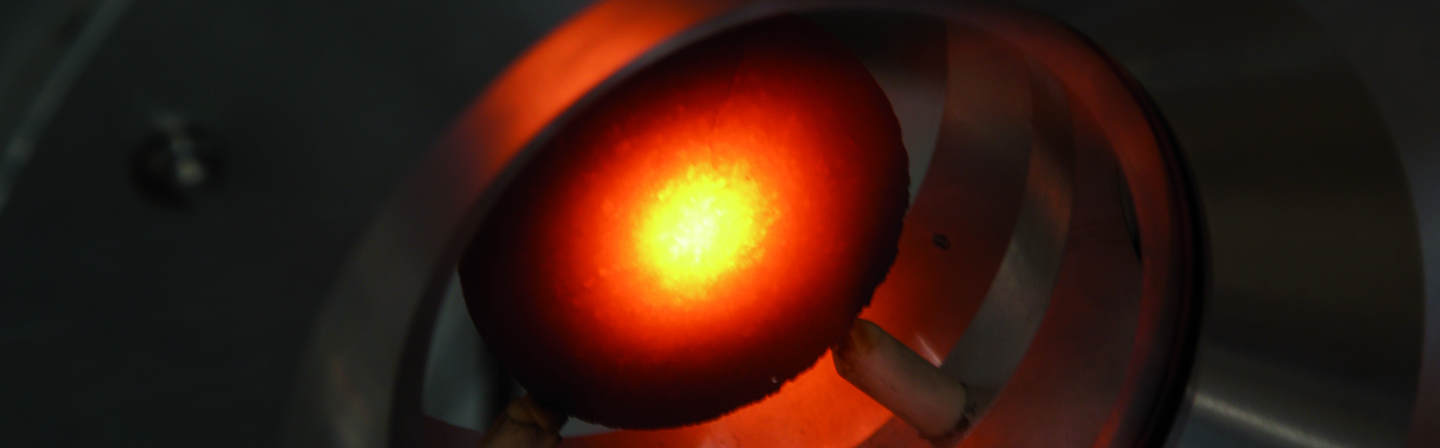

The HTL develops ThermoOptical Measurement Furnaces (TOM) in which the industrial thermal process is simulated in the laboratory. All furnace atmospheres relevant in industrial furnaces can be realized: combustion atmospheres, air, inert gases, forming gas, hydrogen, vacuum, overpressure, etc. The systems are equipped with numerous detectors that can accurately monitor material changes during thermal treatment. In addition, a thermophysical characterization of materials can be carried out. Some TOM systems are specifically designed for relatively lower temperatures to simulate industrial conditions as accurately as possible for debinding/pyrolysis processes (publication: Radical Time Reduction of Debinding Processes) and drying, while high-temperature measurement furnaces are available for sintering (publication: Simulation of Sintering) and melt infiltration (publication: Fundamental Mechanisms With Reactive Infiltration). In-situ measuring parameters include thermal expansion, sintering shrinkage, distortion, thermal conductivity, emissivity, heat capacity, heat of reaction, weight change, gas emission, sound emission, wetting, creep rates, viscosity, and thermal shock resistance. In contrast to conventional thermal analysis methods, TOM systems typically cover a measurement volume of about 10 to 100 cm³. They can also reproducibly measure properties of sm

For targeted process optimization, the measurement data is parameterized. In particular, the kinetics of thermally activated reactions are represented with robust models and then used in FE simulations to optimize the thermal processes on the computer. The FE models also take into account the interaction between the industrial furnace and the charge, so that the laboratory results can subsequently be transferred to the production scale. For production furnaces, the HTL offers methods for investigating temperature distribution, furnace atmosphere, and heat balance (see industrial furnace analysis). These measurement data can also be considered in FE models and used to optimize the thermal process with regard to product quality and energy efficiency.

Service Offering:

- Characterization of the behavior of solids and melts during the heat treatment process

- In-situ investigation of drying, debinding, pyrolysis, sintering, melting, and infiltration processes using TOM systems

- Measurement of dimensional changes: sintering shrinkage, warping, thermal expansion, and melt formation during sintering

- Measurement of gas-phase reactions: weight change, gas emission during drying, debinding, and sintering

- Thermophysical characterization of solids: thermal conductivity, creep resistance, emissivity, high-temperature strength, high-temperature modulus of elasticity, and thermal shock resistance

- Characterization of melts: wetting, viscosity

- Simulation of heat flows and temperature fields to develop energy-efficient temperature cycles with shorter total duration (cold-cold), e.g. during debinding and sintering

- Development of heat treatment processes with lower scrap rates and reduced post-processing efforts

- Customer-specific development of high-temperature measurement methods for all common furnace atmospheres.

Further Publications:

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth