Completed funded project

About 7 % of primary energy in Germany is consumed for industrial heating processes with process temperatures above 1000°C. These high temperatures are mainly required for the production and refinement of inorganic materials and for energy generation. The energy costs of heat treatment contribute significantly to the manufacturing costs of metals and ceramics, at around 5-20%. The energy efficiency is so far below the theoretically achievable value. Material efficiency is equally important. This can be increased by reducing reject rates during heat treatment.

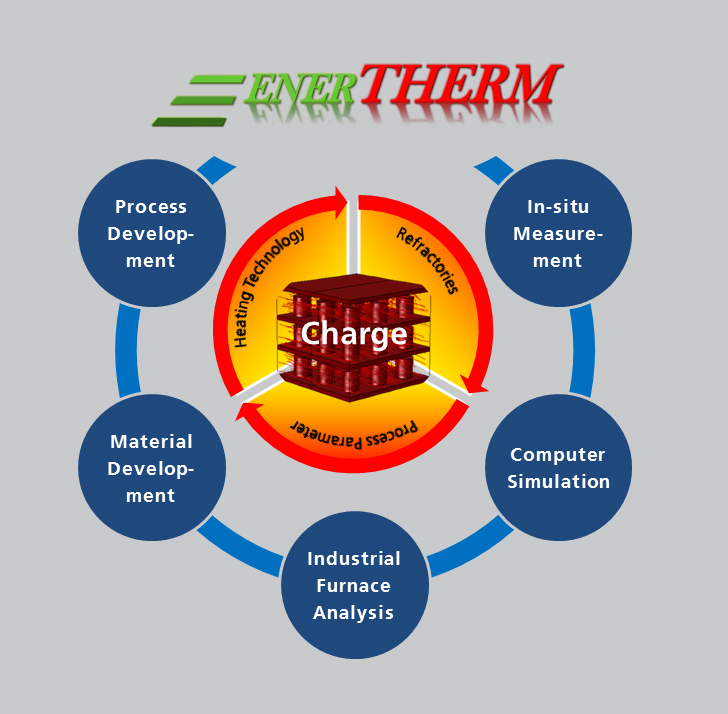

The EnerTHERM project aims at significantly improving industrial heat treatment processes in terms of:

• Energy efficiency

• Material efficiency

• Product quality

The focus lies on high temperature processes with temperatures above 1000°C. The project should make an important contribution to reducing CO2 emissions from energy-intensive manufacturing processes.

The EnerTHERM project includes the following focus areas:

• High temperature characterisation of materials

> Development ThermoOptical Measuring Devices (TOM)

• Measuring of industrial thermoprocessing plants

> Development of mobile analysis system

• FE-simulation and optimisation of thermal processes

• Development of HT materials

• Development of systems for HT applications

Within the EnerTHERM project there is a close cooperation with the operators and manufacturers of heat treatment plants as well as with the manufacturers of high temperature materials and components.

It is funded by the Bavarian State Ministry of Economics and Media, Energy and Technology.

Funding: 9,5 Mio. Euro

Duration: 09.2012 - 12.2018

Organisation: 8 networked sub-projects

- Characterisation of high temperature materials with regard to application properties and durability

- Characterisation of industrial thermoprocessing plants

- Optimisation of heat treatment processes regarding the CO2 balance

- Improvement of thermoprocessing plants

- Development of lightweight materials for high-temperature applications

- Development of technologies for the cost-efficient production of HT components and systems

- Energy efficiency in continuous heat treatment plants: SiC/SiC components for roller kilns

- Energy efficiency in continuous heat treatment plants: design of roller kilns

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth