As a clean energy carrier, hydrogen will replace fossil fuels in many heating processes. There is still a high R&D demand for the efficient production, storage and use of hydrogen. Fraunhofer Center HTL is working on all three topics, with a focus on investigating heat processes with hydrogen.

Hydrogen

One way to produce hydrogen is by high-temperature electrolysis. For this purpose, solid oxide fuel cells (SOFC) are developed, whose electrolyzer mostly consists of a ceramic oxygen ion conductor (ZrO2) and electrode layers that are sintered simultaneously. The HTL has many years of experience in this co-firing. The existing ThermoOptical Measurement (TOM) equipment and sintering models are perfectly suited for in-situ measurement and optimization of co-firing processes. In addition, special crystallizing glass solders with adapted expansion coefficients have been developed to seal the SOFC. Currently, the use of ceramic materials as electrodes in alkaline electrolysis processes is also being investigated.

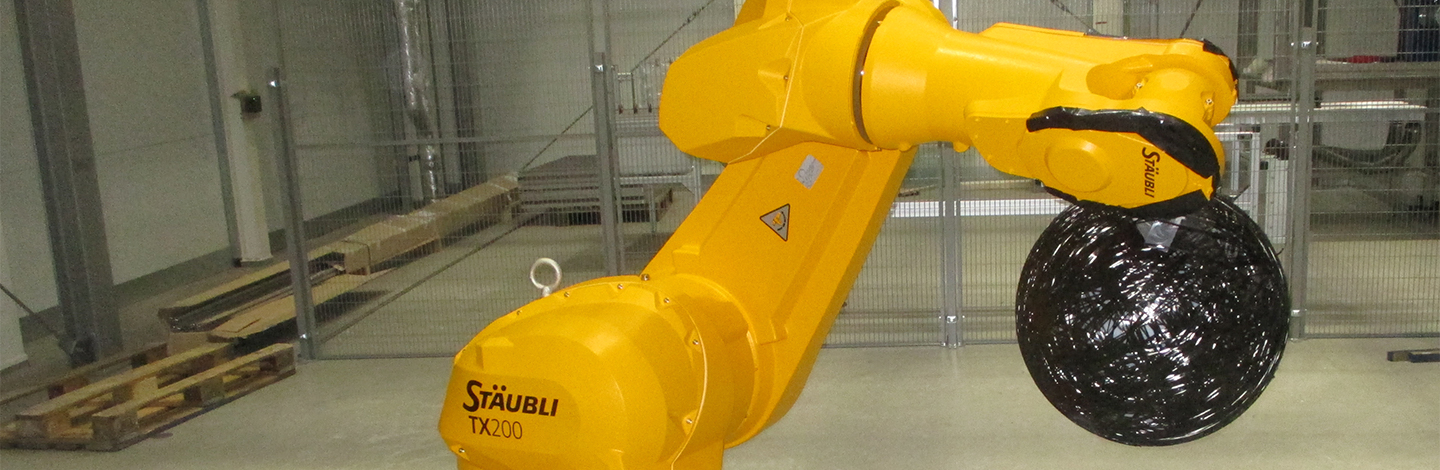

When hydrogen is used as an energy carrier in the transportation sector, the volume and weight of the tanks must be carefully minimized. The HTL is involved in the development of particularly lightweight hydrogen tanks. The principle is based on the use of spherical inliners made of hydrogen-tight polymers, which are wrapped with carbon fiber bundles to withstand the pressure on the inliner. The spherical shape allows the stresses to be distributed evenly (isotensoidally) and significantly reduces the wall thicknesses and thus the weight of the tanks. The robotic winding technology was developed at the HTL. The HTL also has non-destructive methods for product inspection of hydrogen tanks. These are based on a computed tomography system that can be used to examine components up to 700 mm in diameter.

The HTL has a measuring furnace (TOM_metal) which can be used to carry out heat processes in hydrogen atmospheres up to temperatures of 1800°C. Dimensional changes can be measured in situ. The furnace is used, for example, to optimize powder metallurgical sintering processes. Aging experiments or reduction processes in hydrogen-containing atmospheres can also be carried out in TOM_metal.

In addition, another measuring furnace (TOM II) has been developed at the HTL to flexibly simulate the atmospheres generated during the combustion of hydrogen or hydrogen/natural gas mixtures. In TOM II, reducing, inert or oxidizing atmospheres can be used. Weight and dimensional changes are measured during heat treatment. TOM II is used for in-situ measurement of sintering processes in hydrogen-fired furnaces and for investigations of the corrosion behavior of high-temperature materials under hydrogen exposure. After exposure, corrosion phenomena can be investigated by microstructural analyses and thermodynamic calculations. The optimization of sintering processes under hydrogen or steam atmospheres is carried out with the established sintering models of the HTL. With the help of digital furnace twins, the HTL can design industrial heating processes using hydrogen as an energy source.

Silicon-free, high-temperature resistant EBC (Enviromental Barrier Coatings), as required for hydrogen combustion applications are also being developed at the HTL.

Service Offering:

- Experiments with in-situ measurement under defined hydrogen-containing atmosphere

- Corrosion investigations after high-temperature operation in hydrogen-containing atmospheres

- Optimization of sintering processes in hydrogen containing atmospheres

- Design of heat processes with hydrogen combustion

- Non-destructive testing of hydrogen tanks

- Development of co-firing processes for SOFC

- Development of glass solders for SOFC

- Development of hydrogen resistant coatings

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth