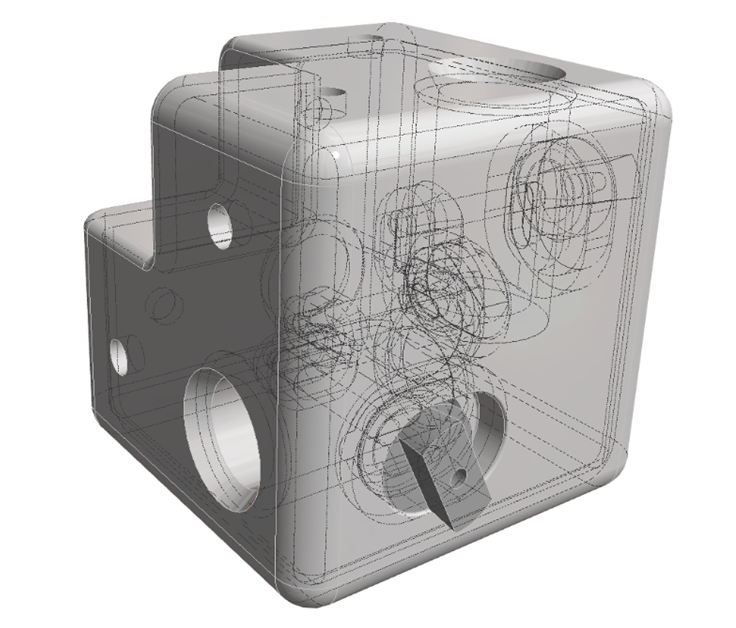

Nowadays, computer-aided material and component development (ICME) also includes material and energy efficiency as a central criterion for the production and use of components. Modern methods of topology optimization make it possible to develop ceramic and metallic components with minimal mass and heat capacity for specific applications. Thanks to advances in forming processes such as additive manufacturing, injection molding, or textile methods, the necessary often complex geometries (e.g. cellular structures) can be industrially manufactured. Fraunhofer Center HTL uses proven procedures for automatic topology optimization such as density-based, level-set, or grid-based algorithms for component design. It is further developing the methodology within current R&D projects regarding efficient thermal processes. The necessary material properties can be measured at the HTL, and prototypes can be produced and tested. Current examples include the development of topology-optimized, lightweight kiln furniture and the design of multi-layer thermal insulation and radiation shields.

Topology Optimization

Thermal processing, particularly sintering, almost always requires high-temperature resistant kiln furniture, on or in which the actual charge is placed in the furnace. Especially in continuous furnaces, the amount of heat required to heat the kiln furniture can make up the majority of energy losses in the process. To tap this significant energy-saving potential, the HTL develops topology-optimized kiln furniture with minimal heat capacity. Basis are mechanical and thermal finite element analyses, which nevertheless meet the requirements for stiffness, creep stability, and thermal shock resistance. The effective and homogeneous heating of the material being heated may also be considered as a criterion in the topology optimization as a secondary condition. Depending on the application, only the support structures may be designed with more filigree designs or all kiln furniture components can be designed as cellular/grid-based structures. They can be realized, for example, through additive manufacturing. An approach for more affordable kiln furniture using paper-based manufacturing processes for ceramic shaping is currently being developed.

The design of multi-layered thermal insulations is a special case of topology optimization. For this purpose, an independent software (user app based on COMSOL) has been developed, which automatically determines the optimal thicknesses of individual layers for minimal heat transfer at manually specified material sequence and total thickness. The heat transfer through radiation in gaps or at radiation shields is also simulated. The temperature dependence of material properties is taken into account in the models, as well as the maximum operating temperatures of the materials. For a more comprehensive redesign of insulation, materials are selected using systematic tools. If necessary, further FE analysis related to the specific application is carried out determining mechanical and thermal stresses in the insulation. The required material data for thermal conductivity and emissivity can be measured at the HTL as a function of temperature. The simulations can be experimentally validated using special furnaces.

Service Offering:

- Delivery of studies for topologically optimized components

- Production of topologically optimized prototypes with 3D printing

- Design and production of topologically optimized textile structures

- Development of energy-efficient kiln furniture

- FE modeling of the performance under thermal and mechanical loads

- Conception of thermal multilayer insulation and radiation shields

- Development of customized software for the design of furnace walls and other thermal insulation

- Measurement of material properties for the design of topologically optimized structures

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth