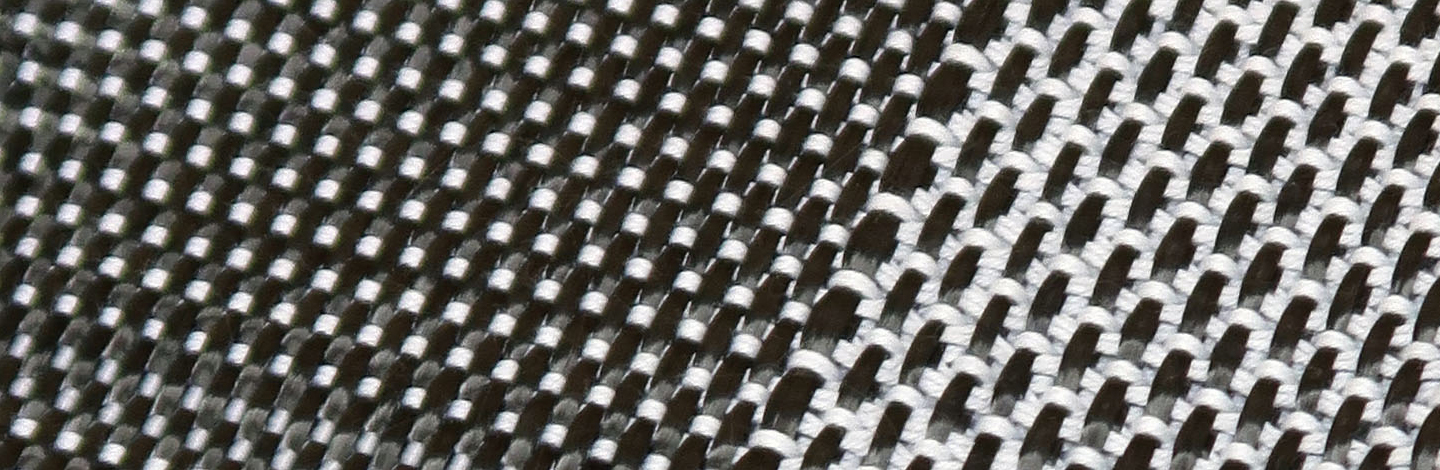

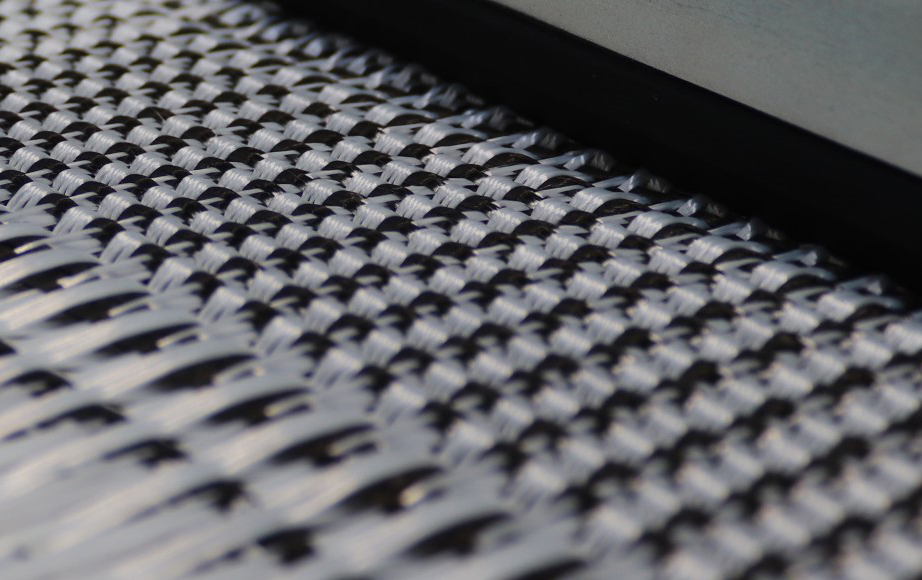

At Fraunhofer Center HTL, samples of ceramic materials, ceramic fibers, textile semi-finished products, prepregs, and fiber-reinforced composites can be produced under both laboratory- and near-series production conditions. The HTL has suitable facilities available for this purpose, which allow reproducible and cost-effective production. In addition to additive processes in ceramic manufacturing, continuous and robot-assisted processes are used for fiber composites.

Sampling

As part of material development, the basic production parameters are developed and documented. The HTL initially advises on the selection of a suitable material for the planned application. If a material with suitable product properties is already available, the production of samples can be started directly. If the required materials or properties are not yet available, the HTL advises on the necessary development steps to improve the properties. This optimization can also be done with the support of simulation tools.

For sample production, the geometry, surface finish, and permissible tolerances are required from the customer. Complex structures can be generated through joining processes or finishing. The processing of samples and components to the exact final dimension can be done through finishing on a 5-axis machining center.

If the material properties are sufficient from the customer's point of view for the application, upscaling of the specified process can be carried out while adhering to the predefined process parameters. This ensures high reproducibility, which can be demonstrated with the help of small series. The reproducibility of properties can be demonstrated with norm-based testing procedures that have already been established at the HTL.

In the case of planned series deployment, the HTL enables technology transfer to industry with the developed know-how.

At the HTL, various non-destructive testing facilities are available for quality assurance of materials and components. The testing procedures for sample testing are coordinated with the customer. They aim at detecting possible material defects or geometric deviations that could affect product performance. The critical errors are documented in an error catalog. Based on this, release criteria can be established. The investigations also serve to optimize individual manufacturing steps before scaling up the entire process.

Service Offering:

- Consultation for initial selection of material samples made of ceramics, textile semi-finished products, prepregs and fiber-reinforced composites

- Application-specific material optimization using simulation tools

- Optimization of manufacturing processes to increase quality

- Establishment of procedures for sample testing

- Establishment of release criteria for products and processes

- Conducting standardized testing of samples

- Consultation on the selection and determination of equipment and procedures

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth