Currently funded project

Motivation

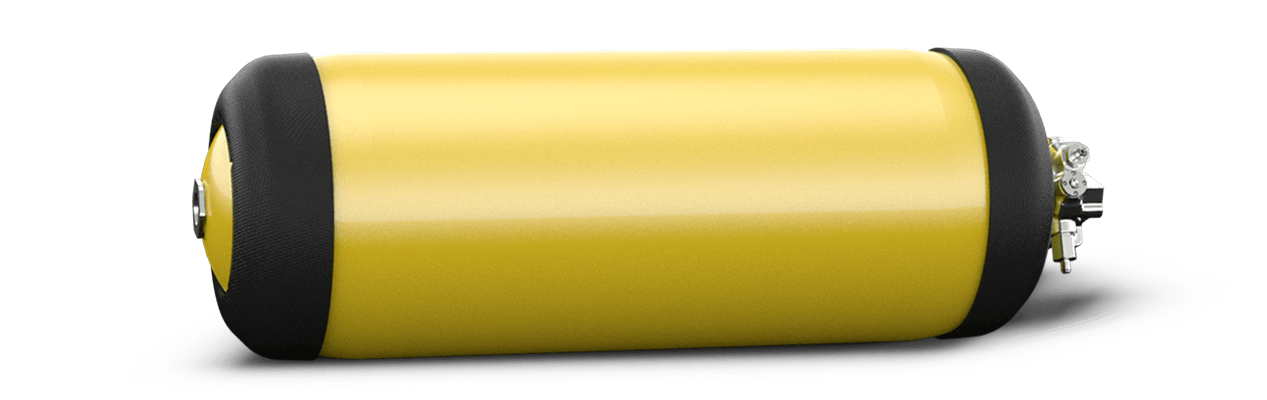

Hydrogen pressure tanks available on the market so far are all cylindrical.

Although this common tank geometry offers good utilisation of the installation space, the potential for weight reduction has been largely exhausted. For physical reasons, the required wall thickness in the cylindrical area of the tanks is twice as high as in the spherical area (=> "tank formula"). Thus the spherical design contains

an enormous potential in terms of material and thus weight and cost savings.

Objective

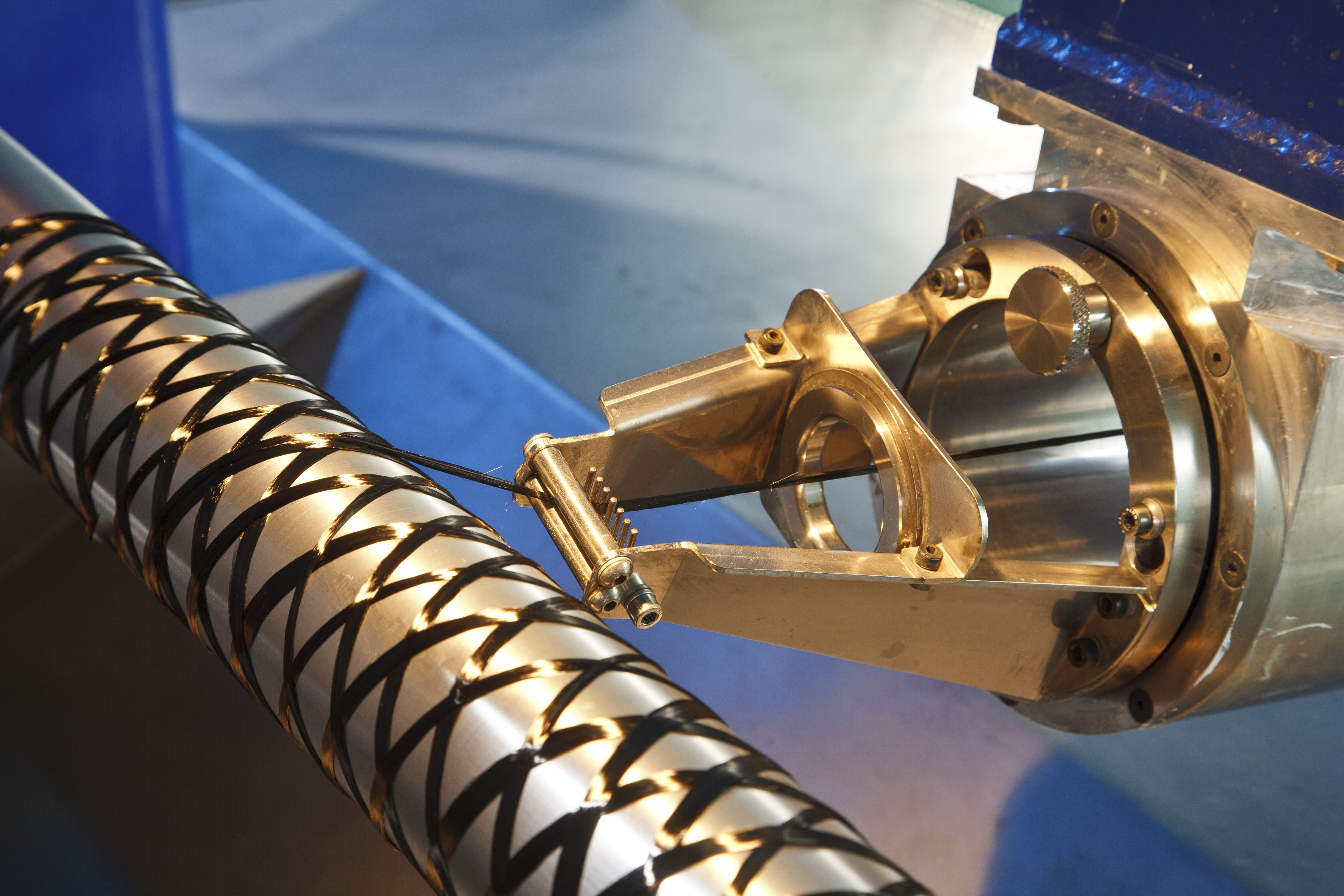

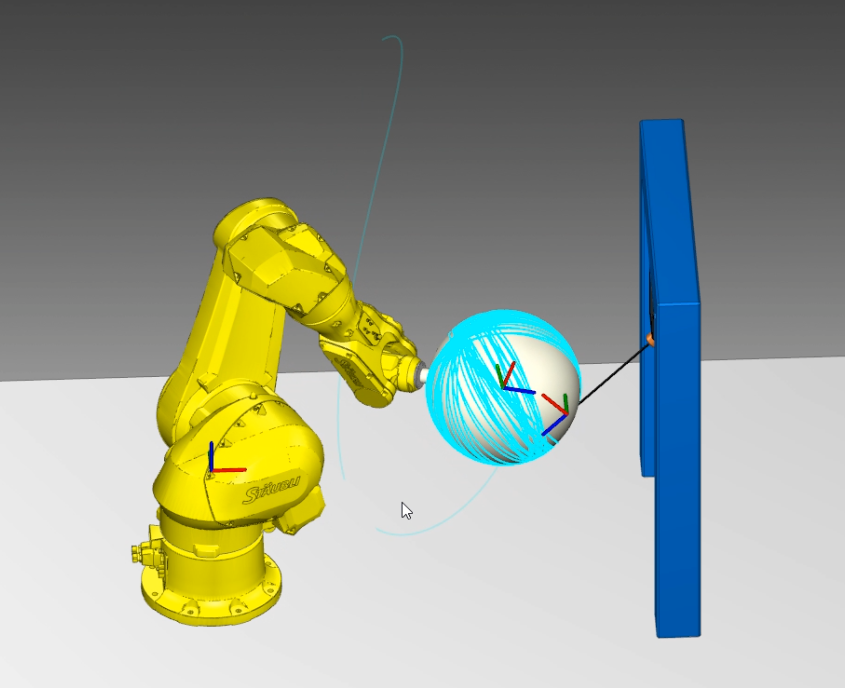

The project will develop a spherical isotensoidal high-pressure tank for storing hydrogen at 350/700 bar. The tank will be made of carbon fibre reinforced plastics (CFRP) and by automated forming processes such as winding or tape deposition. The isotensoid fibre deposition transfers the pressure load to the fibres in such a way that their high strength can be used optimally. Furthermore, a hydrogen diffusion barrier is to be integrated into the CFRP wall of the tank. For this purpose, special diffusion-inhibiting ORMOCERE® (organic-inorganic hybrid polymers) are to be used as matrix material. In addition, further barrier layers can be integrated into the structure. The pressure tanks are to be used as hydrogen storage in stationary and mobile applications. The fibres used are to be recycled at the end of their useful life.

Approach

Project Data

| Project Duration | 01.09.2020 - 31.08.2022 |

| Sponsor | Bavarian Research Alliance (BayVFP) Materials and materials promotion line |

| Funding Amount | 330,000 Euro |

| Project Partners | Fraunhofer-Centre HTL PS-HyTech GmbH robotized rm systems GmbH Kiwa Deutschland GmbH |

| Project Coordination |

PS-HyTech GmbH |

| Project Management at the HTL | Jan-Marcel Hausherr |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth