Completed funded project

Motivation

Thermal treatment is an important link in the value chain of many materials. The interaction between the furnace system and the material to be heated is crucial for thermal process development. By using digital methods (AI methods, digital furnace twin), which are developing rapidly, thermal processes can be predicted and optimized. There are also important developments in sensor technology - both within and outside the DiMaWert project - that can be used for process control. The combination of process simulation and modern sensor technology can significantly shorten process times and drastically reduce energy requirements.

Objective

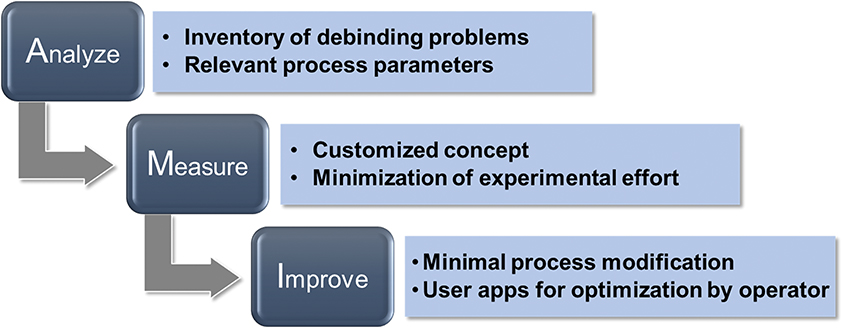

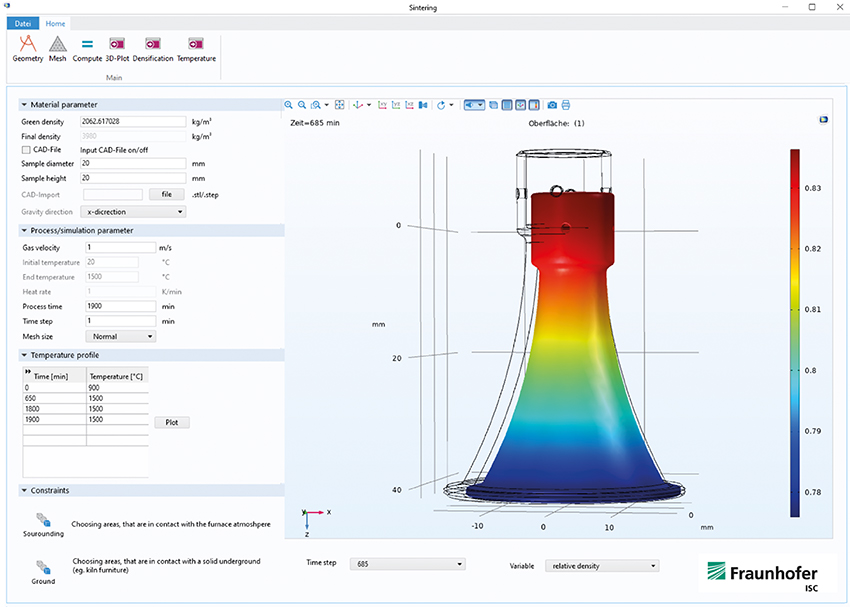

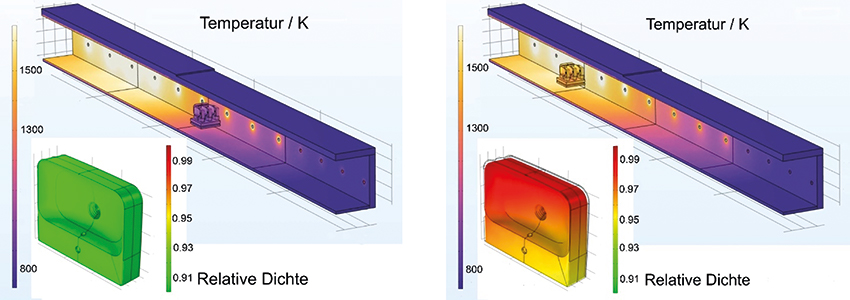

In this sub-project, the simulation models for the development of thermal treatment processes were to be further developed. In particular, the transfer to bulk materials was planned. The existing models for debinding and sintering processes were to be deepened. The material models were to be combined with virtual furnace twins in order to optimize the process parameters. Control concepts were to be developed for the virtual furnaces. In addition, a methodology for the optimization of industrial drying processes was to be developed.

Results

- Development of user apps that enable users to optimize their thermal processes independently

- User apps for debinding, sintering and bulk material processes

- Development of a control system for the digital furnace twin

- Coupling the material models with the digital furnace twin for holistic optimization of thermal processes

- Validation of the simulation methods

- Development of an in-situ measuring system for the investigation of drying processes under the conditions of industrial drying plants

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth