Motivation

To improve the energy efficiency of heating processes, the optimisation or new development of high-temperature resistant materials offers various promising possibilities. For example, the heat capacity of ceramic carrier materials can be directly influenced by introducing pores. Thinner or more robust components can also be created by using ceramic fibres.

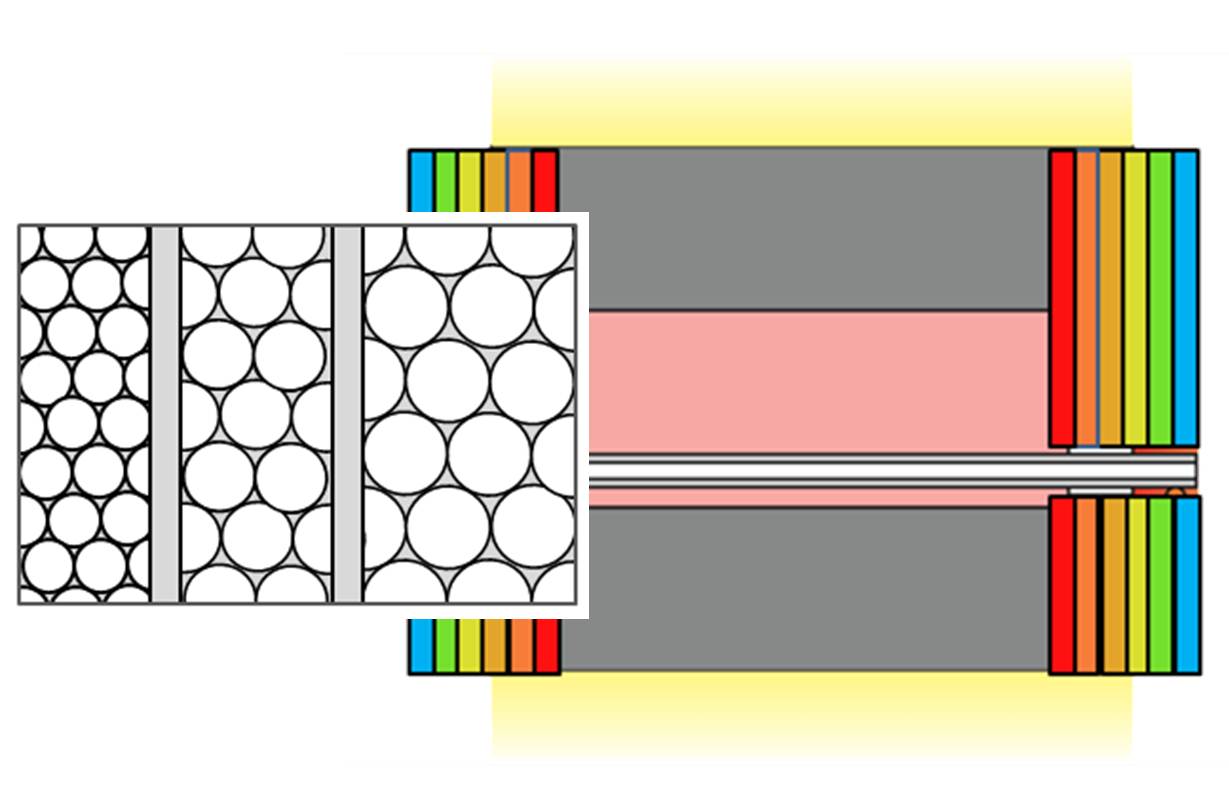

In the field of insulation applications, porous insulation materials specially adapted to the temperature profile of the respective furnace are of particular interest. These could efficiently absorb thermal radiation in a wide radiation spectrum using a multi-layer structure or a graded porous structure.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth