Fraunhofer Center HTL has methods for developing ceramics and powder metallurgical materials throughout the entire production chain. From the formulation preparation and shaping processes to the heat treatment and final processing, oxide ceramics, non-oxide ceramics, silicate ceramics, powder metals, and fine-grain graphite can be produced. Special metal-ceramic composites and hard metals are also developed at the HTL.

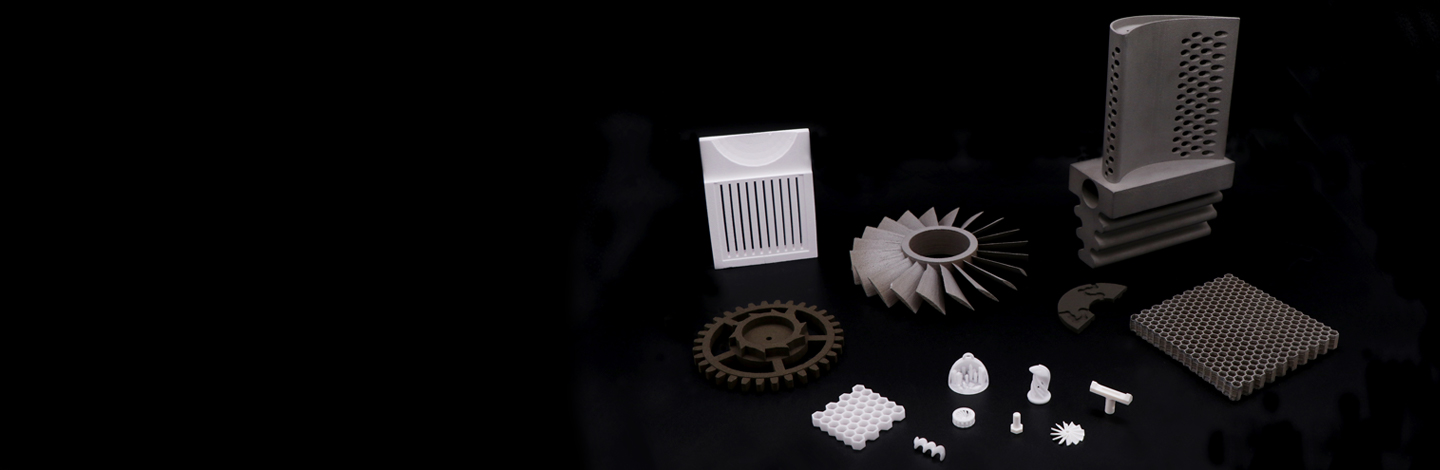

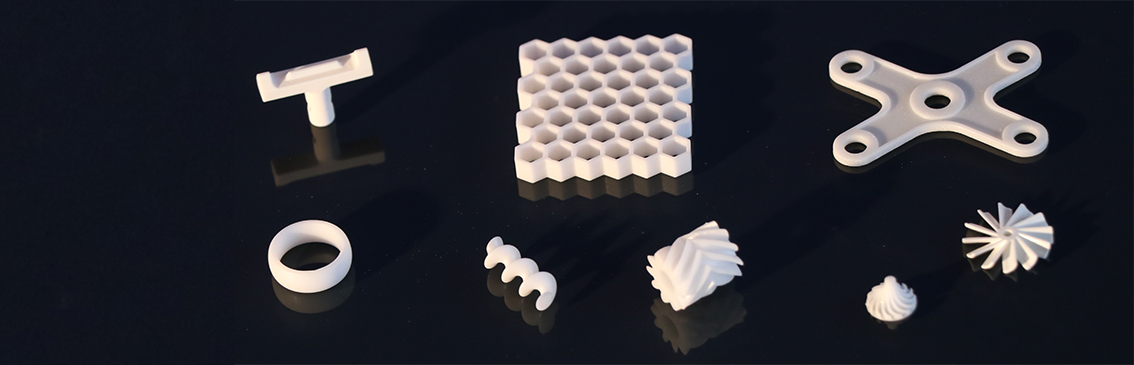

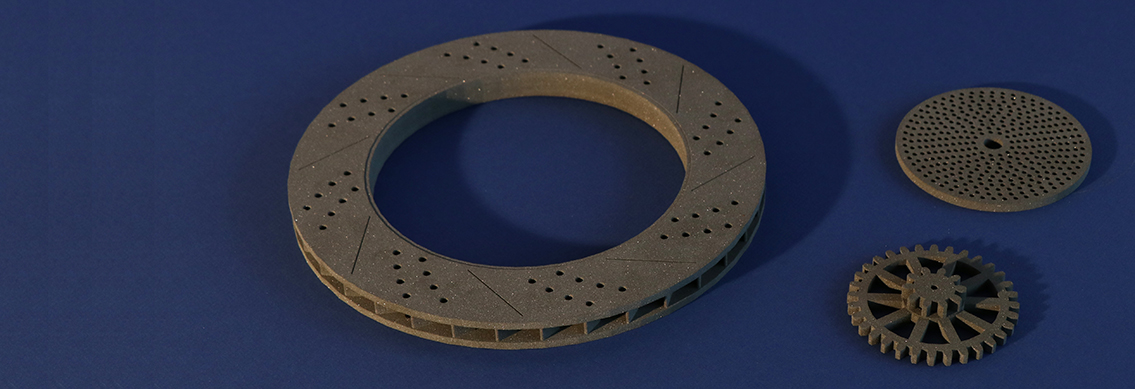

A particular feature of the HTL is 3D printing using quality-assured methods. Additive manufacturing can be done using both slurry-based and powder-based processes, enabling the production of components with complex geometries.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth