Completed funded project

Motivation

Optical monitoring of the furnace interior during operation provides valuable information about the condition of the insulation without waiting time and the request of cooling the furnace down, as was previously the case. Due to the high temperatures, however, special demands are placed on the image recording systems used. The electronics must be shielded against the high temperatures and at the same time the optical information must be transmitted to the camera. The preconized approach is a temperature-resistant front lens collecting rays while simultaneously acting as a heat transmission barrier.

Objective

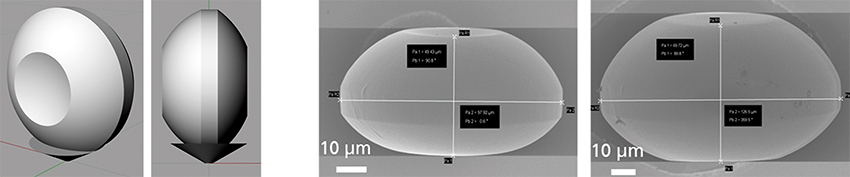

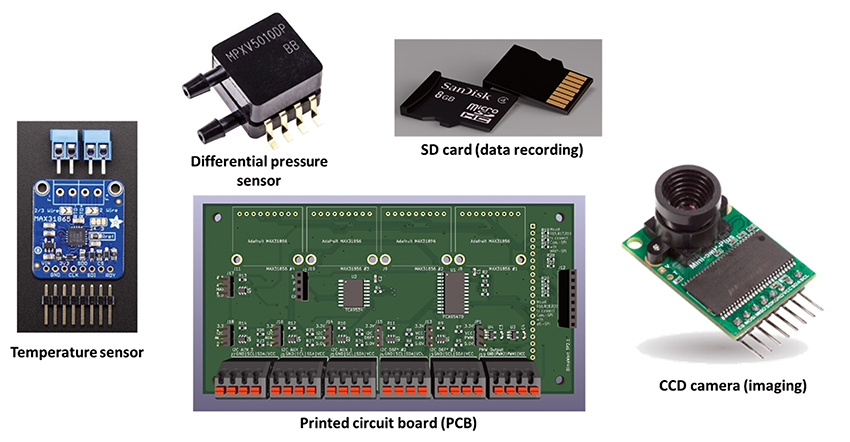

The aim of this sub-project was to develop an autonomous sensor module that works without an external power supply and that detects damage in furnace insulation. For this purpose, a keyhole diagnostic system was to be developed in which the camera and the electronics are protected against the high furnace temperature in a heat protection container. A front optic lens made of a temperature-resistant transparent material had to be designed and produced. The objective is to record optical information from the furnace, with high light intensity, which is also collected from a wide image angle. The information is then transmitted to a camera via a narrow tube. The camera, the power supply and the data memory should be kept at temperatures of approximately 100 °C in a heat protected container. Investigation of whether additive technologies can be used to produce free-form lenses of high optical quality are also on the way.

Results

- Quartz glass proved to be a suitable material for front optics (maximum operating temperature up to 1,100 °C).

- ORMOCER®, which was selectively cured by means of 2-photon polymerization and then pyrolized, proved to be suitable for the additive production of micro-freeform optics.

- Thermal management for the ASM was successfully implemented using a phase change material (see sub-project 7).

- The camera, electronics and batteries, which could be used at 100 °C, were selected, programmed and successfully tested.

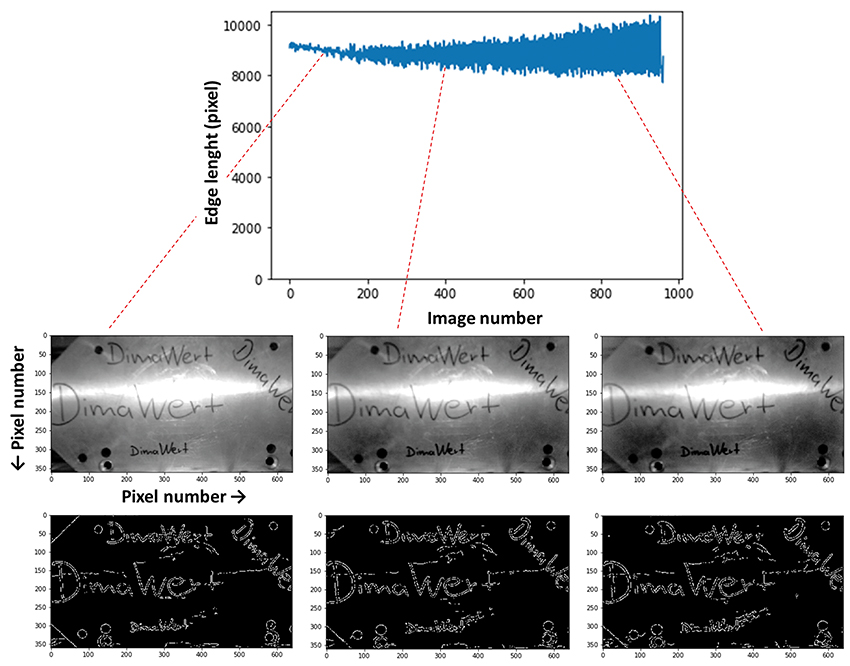

- AI algorithms were developed and tested for image recognition.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth