Compeleted funded project

Motivation

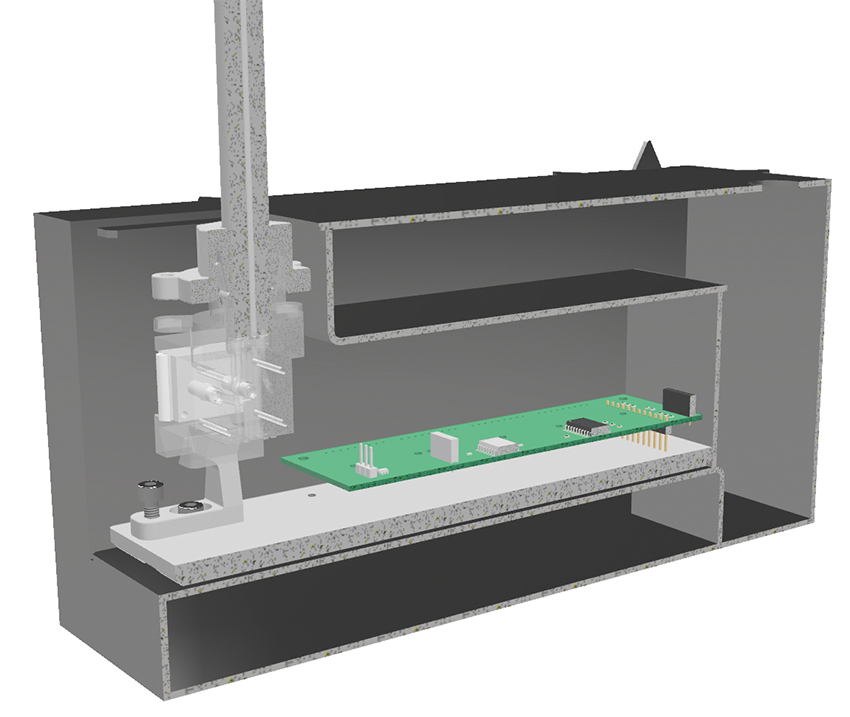

Industrial furnaces are largely a black box because only a small amount of furnace data is recorded at predetermined measuring points during operation. A mobile autonomous sensor module (ASM), which travels through the temperature cycle with the material to be heated, can also be used to obtain a wide range of data. This data is a valuable basis for optimizing heating processes. An experimental prototype for a mobile ASM has already been developed at Fraunhofer Center HTL in previous projects. The electronics for data acquisition and the power supply are located inside the module, whose temperature is limited to 120 °C by a phase change material. The sensor head protrudes into the furnace in order to record temperatures and other furnace data without distortion.

Objective

In this sub-project, the functionality of the ASM was to be further developed for routine use in industrial furnaces and demonstrated using new prototypes.

The following improvements were planned:

- Expansion of the ASM to include optical sensors (see sub-project 5)

- Extension of the sensor functions, e.g. for acoustic detection

- Robust handling of the ASM for use by customers in industry

- Improvement and flexibilization of thermal management in the ASM with regard to longer operating times and more compact modules

- Extension of the application possibilities for heat treatment processes on bulk materials

Results

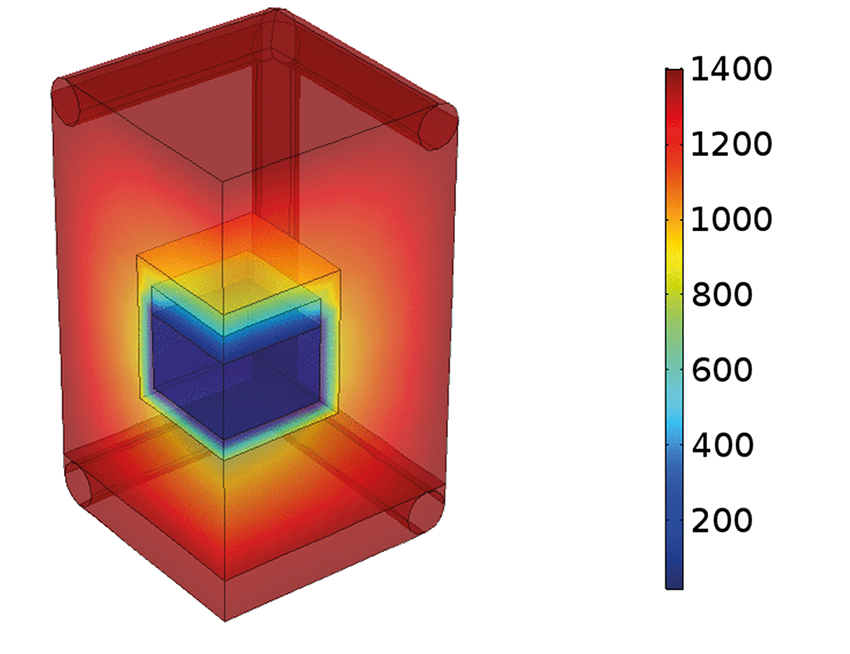

- Creation and validation of a computer model to simulate the heat flows in the ASM

- Development of a methodology for planning and building customer-specific sensor modules with regard to installation space, temperature cycle and furnace atmosphere

- Design of the module for easy replacement of components (design to repair)

- Development of a high-temperature protective coating with low absorption of thermal radiation (low-e coating) and high abrasion resistance

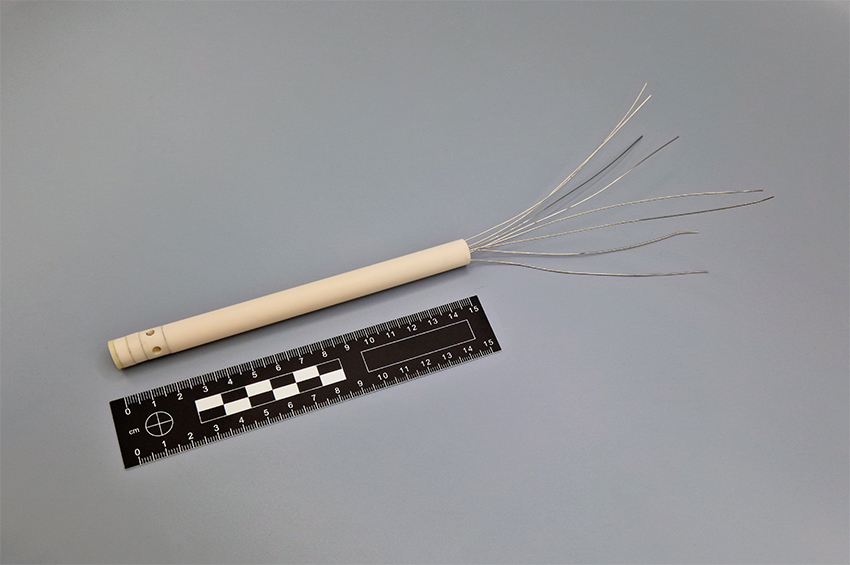

- Development of a robust multifunction sensor for direction-dependent differential temperature and dynamic pressure measurement

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth