Fraunhofer Center HTL works on developing cost-effective and production-ready textile manufacturing processes for inorganic fibers with its Application Center for Textile Fiber Ceramics TFK. Typical materials include silicon carbide, mullite, basalt, carbon, metal, and glass fibers. Similar to additive manufacturing, the textile processes enable the production of 2D and 3D structures that are close to the final shape and material-efficient. Assembly steps can be saved by integrating different components in a textile preform (see AirFox project). The cellular structures are designed to withstand loads. Among others smart textiles and auxetic structures can be produced. The textile structures enable new lightweight applications, such as in aerospace, heat technology, and automotive industry (see Ceramic Matrix Composites CMCs).

Textile Fiber Processing

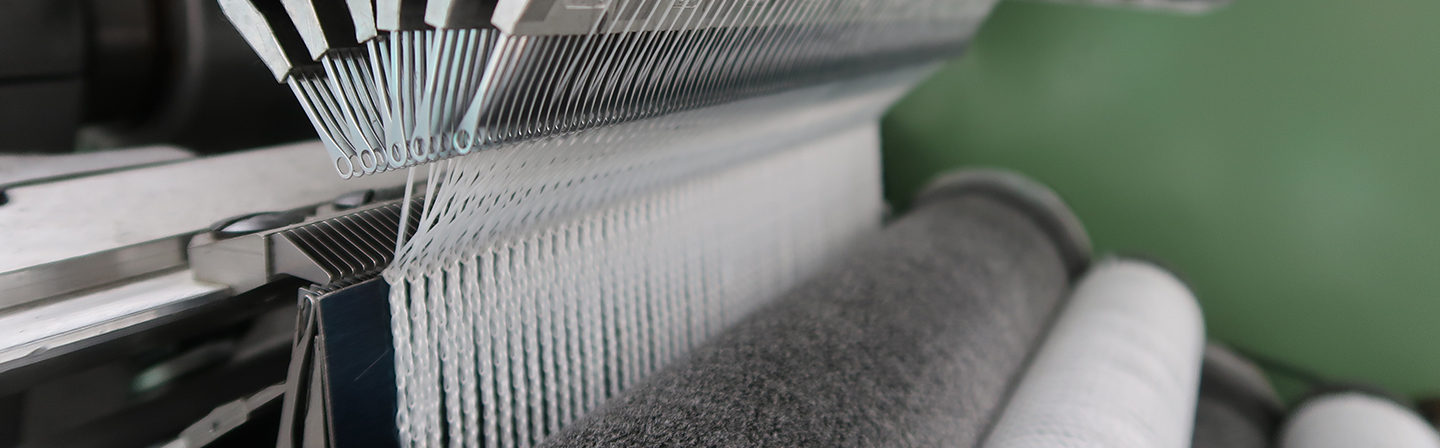

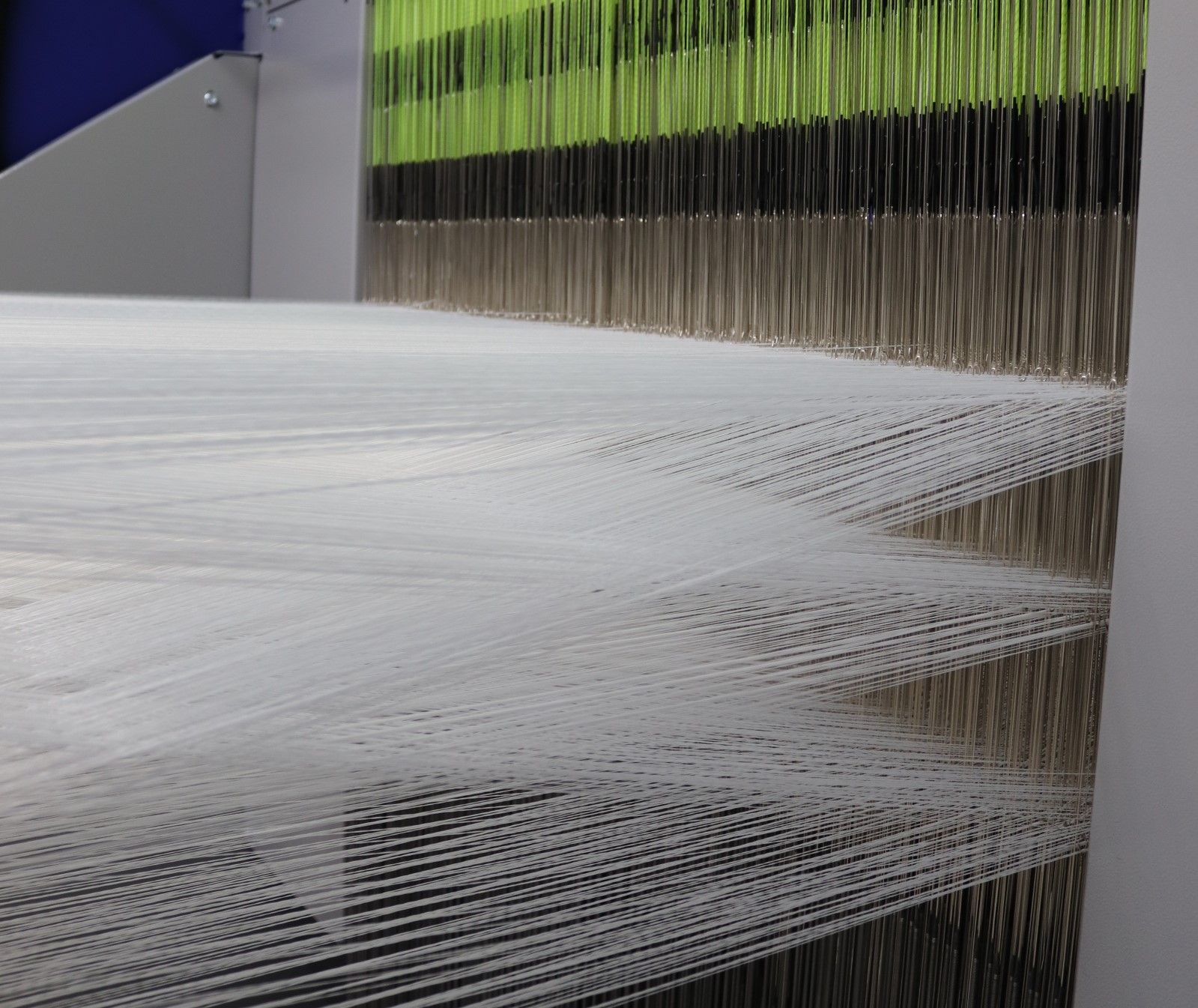

The TFK offers numerous textile processes for weaving, braiding, knitting, warp knitting, and nonwoven production. Highlights include a novel double-gripper weaving machine for spacer fabrics with individual thread control and a variation braider with 24 pneumatic switches. There is also a radial braider with a maximum braiding eye diameter of 800 mm. The maximum width for warp knitting is 1 m. Warp structures are developed for space reflectors, among other applications.

Textile structures made of ceramic reinforcement fibers are an essential part of ceramic matrix composites (CMCs). They contribute to their fracture toughness, impact behavior, corrosion, wear, and thermal shock resistance. This results in a significantly improved lightweight potential at high operating temperatures.

Service Offering:

- Development of textile processing methods for fibers made of ceramics, metals, and glasses

- Modification of fiber surfaces (sizings, coatings)

- Production of textile semi-finished products using weaving, braiding, knitting, warp knitting, and nonwoven processes

- Testing of fibers, textile structures, and composites

Fraunhofer Research Area TECHNICAL TEXTILES

The HTL is a member and contact point in Fraunhofer Research Area TECHNICAL TEXTILES. Fraunhofer Institutes of the Research Area TECHNICAL TEXTILES have joined forces to cover the entire textile value chain from textile machinery, fiber production, preform/semi-finished product production, textile functionalization, smart textiles, process, and product simulation, sustainability - ecological balance, and recycling to fiber composite components.

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth