Completed funded project

Motivation

In the field of aviation, weight reduction and energy efficiency are at the top of the list of requirements for R&D programmes. Ceramic fibre composites (CMC) offer the following advantages for use in aircraft gas turbines:

- Density is 2/3 lower than conventional nickel-based alloys.

- The high-temperature resistance is up to 300 K higher than that of metals.

- The oxidation resistance of O-CMC is naturally high.

- The tendency to corrosion in the combustion atmosphere is low.

In the hot section of gas turbines, CMC components therefore enable more efficient and complete combustion and thus increase the potential of the fuels used. The AirfOx project is intended to expand Bavaria's expertise in the production of 3D components made of CMC.

Objective

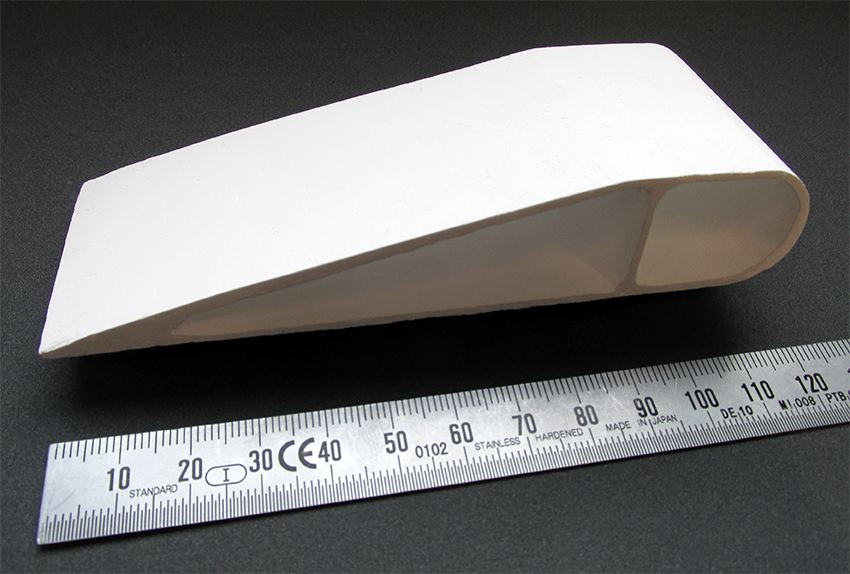

Within the scope of the project, a technology is to be developed with which a near-net-shape 3D preform of engine blades for aircraft gas turbines (airfoils) can be integrally woven from oxidic ceramic fibres and made suitable for series production. This is to be further processed into an energy-efficient high-temperature O-CMC component. The material and component development is supported by multi-scale simulation of the structure-property relationships.

Results

Fibre Production

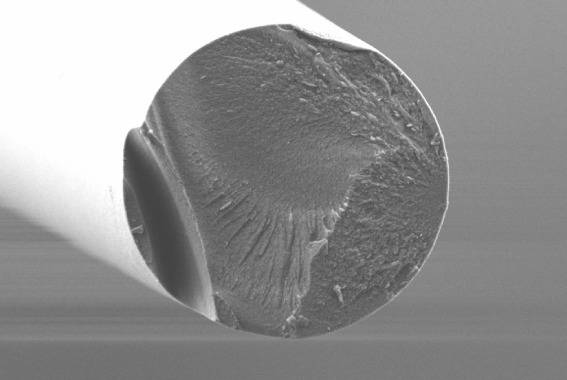

In the course of the project, reinforcing fibres with mullitic or corundum composition were developed for the component design of the Airfoil. For the mullite fibres, which could already be produced with good mechanical properties at the HTL, the focus was on improving the creep behaviour through additives such as ZrO2. For the pure corundum fibres, the feasibility of production on a laboratory scale was demonstrated and an improvement in the mechanical characteristic values was achieved in the subsequent step. The transfer of the results to the fibre pilot plant in Bayreuth will take place after the end of the project.

Preform Development

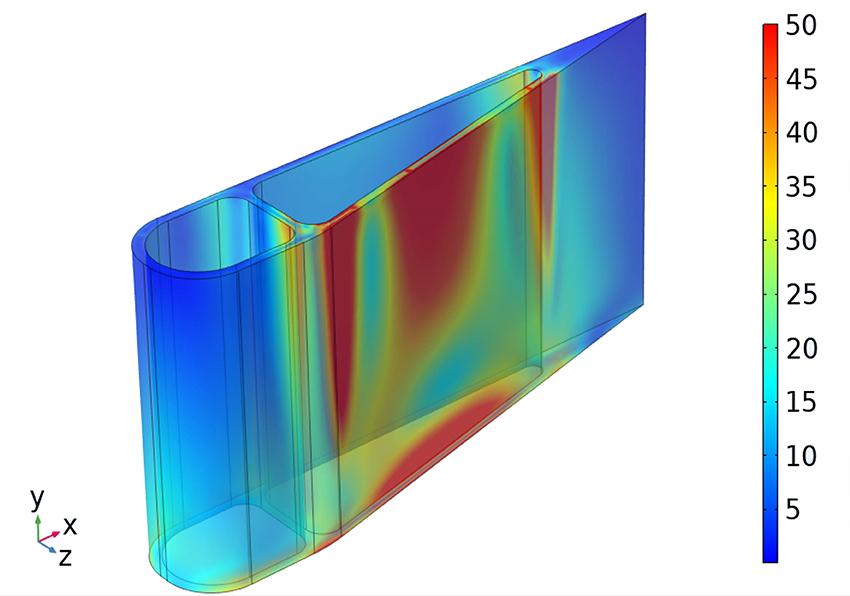

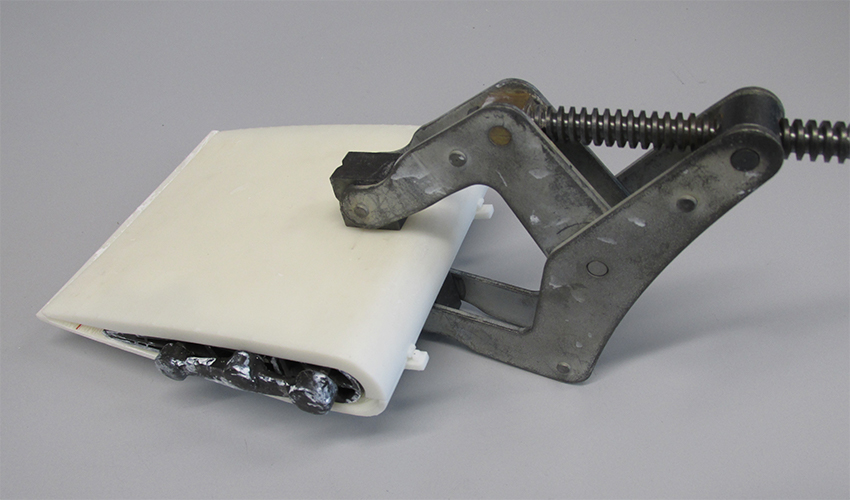

The development of a woven near-net-shape preform for the Airfoil has gone through many development steps. First, the basic feasibility was demonstrated. For this purpose, a suitable weave was developed with the software EAT Weave Composite, which was also used later for the development of the complex multilayer structure of the entire Airfoil. With a highly simplified weave (plain weave in all layers), preliminary tests were first carried out on a semi-automatic laboratory loom. Here, important conclusions could be drawn about the design of the weave with little material input. These findings, together with the findings from the multi-scale simulation carried out in parallel to detect the force curves, were incorporated into the complex weave development. The Airfoil was then first implemented, optimised and parameterised with demonstrator fibres and finally with oxide ceramic fibres on a double rapier weaving machine at the Fraunhofer Application Centre TFK in Münchberg. For this purpose, various adjustments were made to the weaving machine, the creel and machine elements in order to be able to process the demanding, very brittle fibre material.

Production of an Airfoil from O-CMC

For the component production, a suitable infiltration process had to be developed first, with which the 2-3 mm thick walls of the ceramic fibre preform consisting of a multilayer fabric can be completely infiltrated. The process was ultimately designed as a pressure-supported slurry infiltration process with 3 stages in order to achieve optimum results. The Airfoil was then sintered and coated with a glass-ceramic coating.

Project Data

| Project Duration | 01.01.2021 - 30.04.2023 |

| Sponsor | Bavarian State Ministry of Economic Affairs, Regional Development and Energy |

| Funding Amount | 280.000 Euro |

| Project Partners |

Fraunhofer Center for High Temperature Materials and Design HTL / Application Center for Textile Fiber Ceramics TFK |

| Project Coodination | Fraunhofer Application Center TFK |

| Project Management at the HTL | Daniela Albert / Silke Grosch |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth