Fraunhofer Center HTL offers a wide range of mechanical testing procedures at room temperature and at temperatures up to 1500°C for the testing of ceramics and ceramic fiber composites. In addition to standardized testing procedures, the HTL also develops special testing procedures according to customer requirements. Moreover, component testing can be performed with specially designed testing tools. In addition to mechanical testing, the HTL also offers thermal testing with special ThermoOptical Measurement Systems (TOM) developed by the HTL. It is also possible to validate the measurement results using finite element modeling.

Mechanical Testing

Service Offering

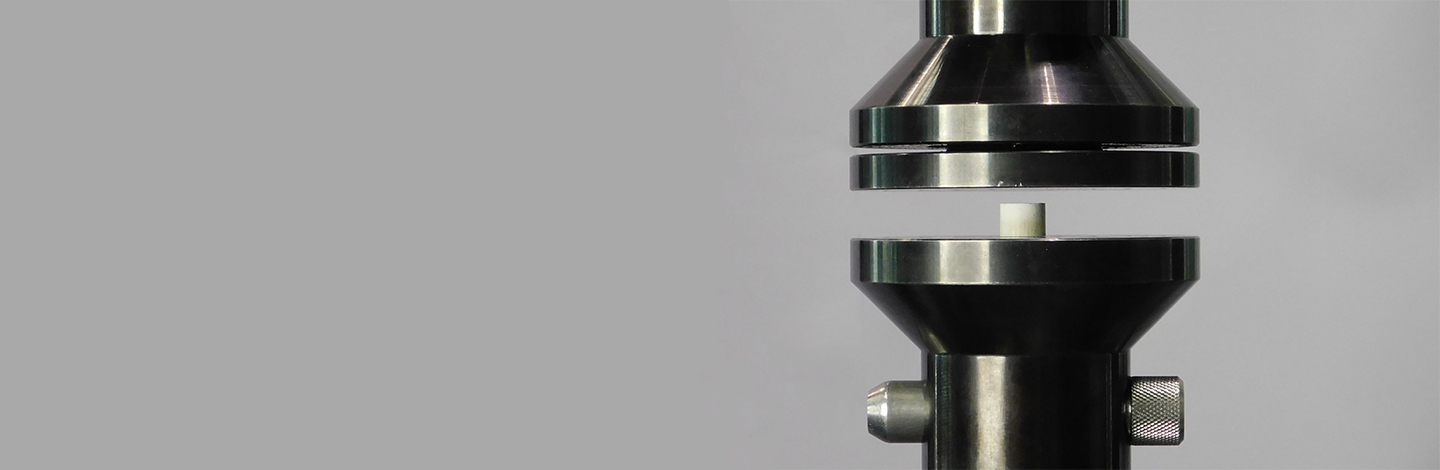

- Tensile testing (various specimen geometries, O-ring test, fiber roving tests, creep tests, etc.) to determine strength, stiffness, fracture strain, proportional limit and Poisson's ratio, e.g. according to DIN EN 658-1, DIN EN 1007-4, DIN EN 1007-5, ASTM C1275

- Tensile testing at temperatures up to 1300°C in air, e.g. according to DIN EN 1893, ASTM C1359

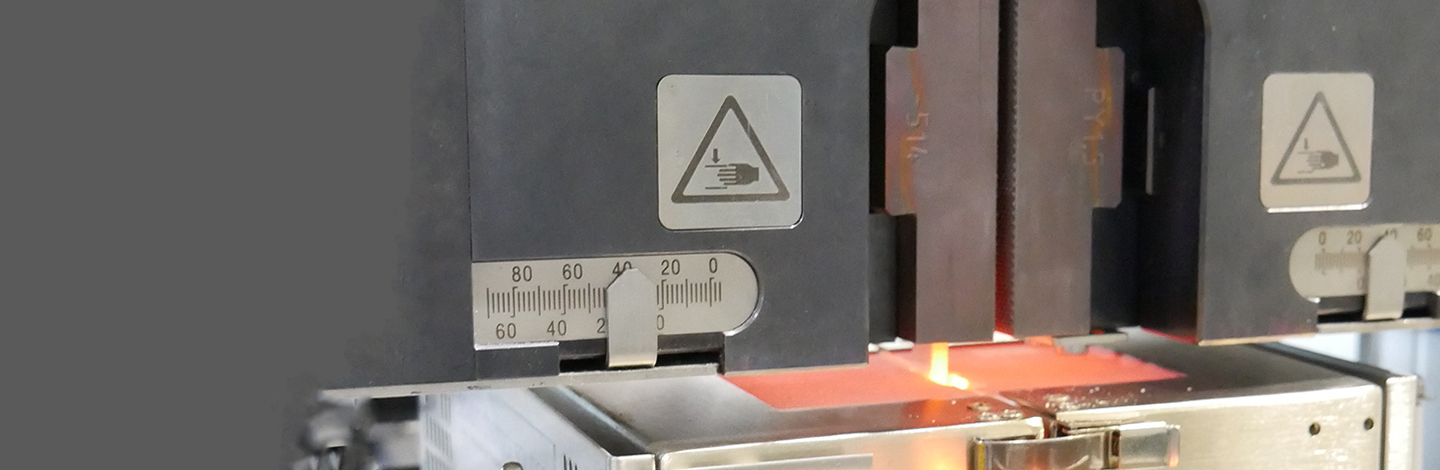

- Determination of bending properties such as strength, stiffness, fracture strain, proportional limit in three- or four-point bending tests, alternatively also as ball-on-ring or ring-on-ring tests, e.g. according to DIN EN 658-3, DIN EN 843-1, ASTM C1161, ASTM C1341

- Determination of bending properties at temperatures up to 1500°C in air, tests under oxygen exclusion with limitations, e.g. according to DIN EN 121789, ASTM C1341

- Compression tests with various specimen geometries (cylinders, flat specimens, C-ring, etc.) to determine compressive strength, stiffness, fracture strain, Poisson's ratio, e.g. according to DIN EN 658-2, DIN EN 843-7, ASTM C1358

- Shear tests in various configurations, such as ILSS, double-notch, Iosipescu or for testing of joining connections, e.g. according to DIN EN 1894, DIN EN 658-5, ASTM C1292

Accredited testing laboratory

The Fraunhofer Center for High Temperature Materials and Design HTL is accredited as a testing laboratory for high-performance ceramics according to DIN EN ISO/IEC 17025-2018 for the following tests:

- Determination of flexural strength according to DIN EN 843-1:2008-08, DIN EN 658-3:2002-11 and ASTM C 1341:2013

- Determination of shear strength according to DIN EN 658-5:2003-03

- Determination of tensile strength according to DIN EN 658-1:1999-01 and ASTM C 1359:2018

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth