Completed funded project

Motivation

Ceramic composites (CMC) have high corrosion resistance and damage-tolerant properties, which are largely retained up to very high temperatures. A major obstacle to their application, however, is the lack of standards for quality assurance and the determination of characteristic values, such as the hardness of these materials. The experience gained with regard to the necessary and permissible test conditions for determining the hardness at the surface is not yet sufficient for the preparation of a standard. The project should close this gap and thus enable the development of a standard for hardness testing of ceramic composite materials.

Objective

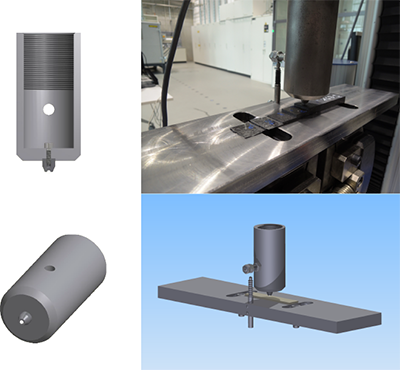

Hardness testing of CMC is challenging due to the heterogeneous structure and high hardness of these materials. Diamond spheres with a diameter of several millimetres have recently become available. In initial tests with such balls the problems described above did not occur, so that hardness testing of CMC now appears to be practicable. The project was therefore intended to develop the basis for a standard for the hardness testing of CMC that would be applicable to all ceramic composite materials.

Results

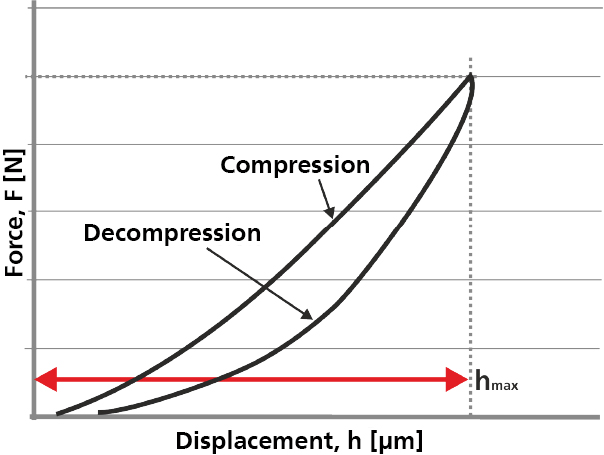

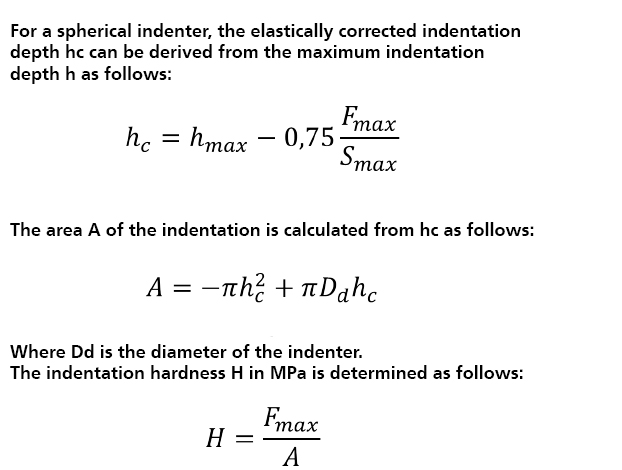

Indentation tests with diamond spheres were carried out on different CMC instruments. Classical measurements of the indenter indentation in CMC were not in a target-oriented manner, so that the focus was on the recorded force-displacement curves. The results formed the basis of an initial test and evaluation specification for determining the hardness of CMC materials. This included the test setup, specified the test specimen as well as the test preparation and execution and showed the test evaluation with determination of the hardness value on the basis of the recorded force-displacement curves. The test and evaluation specification was tested by the project partners in a round robin test.

Project Data

| Project Duration | 01.11.2015 - 31.07.2018 |

| Sponsor | Federal Ministry of Economics and Energy |

| Funding Amount | 164,000 Euro |

| Project Partners | Fraunhofer-Centre HTL Fraunhofer-Institute for Mechanics of Materials IWM German Aerospace Centre |

| Project Coordination | Fraunhofer-Centre HTL |

| Project Management at the HTL |

Dr. Alexander Konschak |

|

|

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth