Currently Funded Project

Motivation

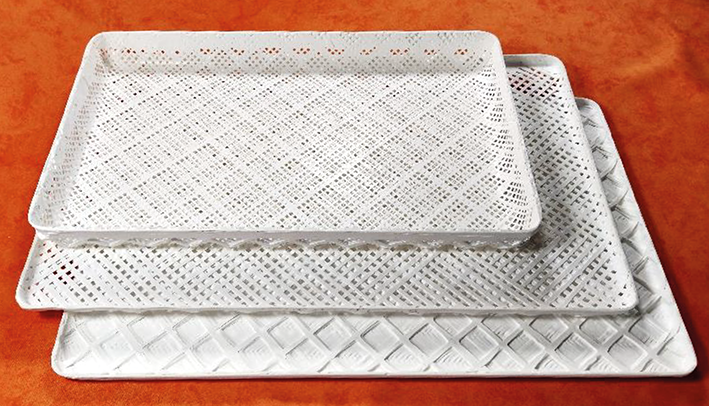

O-CMC (Oxide Ceramic Matrix Composites) are high-strength, creep-, corrosion-, oxidation- and thermal shock-resistant at very high temperatures above 1000 °C and are also insulating. Due to their excellent properties, the use of these new materials in modern heat treatment processes has become increasingly widespread in recent years, displacing conventional materials. However, the reinforcing oxide ceramic long-fiber rovings used in O-CMC are very expensive.

Objectives

The aim of the project is to recycle ceramic roving waste, which is produced during CMC component manufacture in the winding process and is to be returned to component manufacture. Modified material characteristics will result in components that are manufactured in a material- and resource-saving way and are predestined to open up new applications and markets due to their lower costs.

Approach

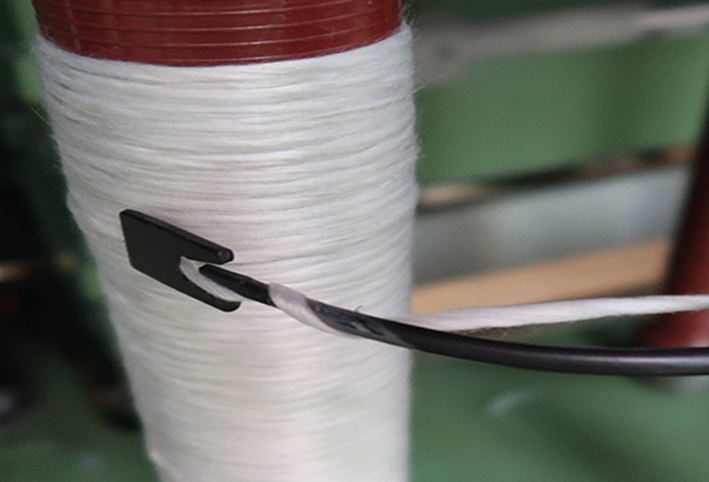

The long fiber offcuts are prepared, cleaned, cut to a defined length, then blended with a carrier fiber and processed into a roving in an adapted yarn production process. The resulting hybrid yarn structure is fed to the winding process as reinforcement material. The material characteristics will also be determined.

- Fiber material: provision, cleaning and cutting of the fiber waste

- Spinning: mixing and yarn production

- O-CMC: winding and component production

Project Data

| Project Duration | 1.9.2022 - 31.8.2025 |

| Sponsor |

Federal Ministry for Economic Affairs and Climate Action |

| Funding Amount TFK | 350,000 Euro |

| Project Partners | Fraunhofer Application Center TFK WPX Faserkeramik GmbH Die Spinnerei Neuhof |

| Project Coordination | Fraunhofer Application Center for Textile Fiber Ceramics TFK |

| Project Management at the TFK | Dr. Andreas Todt |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth