Completed funded project

Motivation

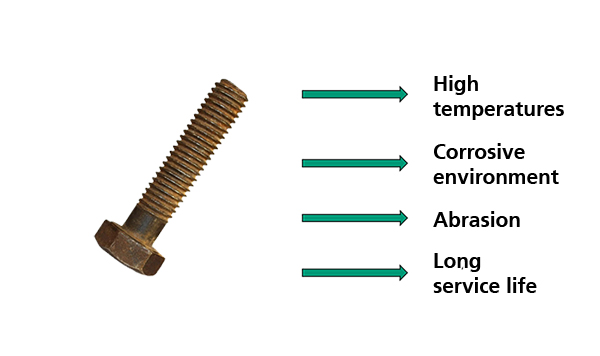

- Use of classic steel screws is limited

- Development of ceramic screws

- Applications: chemical industry, mechanical and plant engineering, aerospace, forming technology, microtechnology, medical technology

- Advantages of ceramics: high temperature stability, corrosion resistance, non-magnetic, low electrical conductivity, abrasion-resistant

- BUT: brittleness, creep at high temperature, high friction coefficients

- Applications: chemical industry, mechanical and plant engineering, aerospace, forming technology, microtechnology, medical technology

Objective

- Zirconia screw connections for use:

- at high temperatures

- in highly corrosive environments

- under high mechanical loads

- for cyclical thermal load (good TCR, low heat capacity)

- can still be removed even after long periods of standing

- at high temperatures

- Post-processing should be avoided

- CNC manufacturing process

- suitable for small and medium series

- processing in green state

- suitable for small and medium series

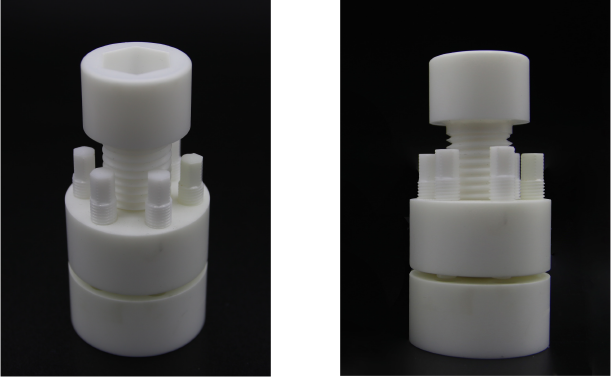

- Superbolt made of ZrO2 ceramic

Results

- Successful material development of MgO partially stabilised ZrO2

- Optimisation of raw material composition, debinding, sintering

- Material properties comparable to reference material (Z 501)

- Optimisation of raw material composition, debinding, sintering

- Design: Finite element analysis for M10 thread

- Development of a design suitable for ceramics that allows a load that is approximately three times higher than a standard DIN thread

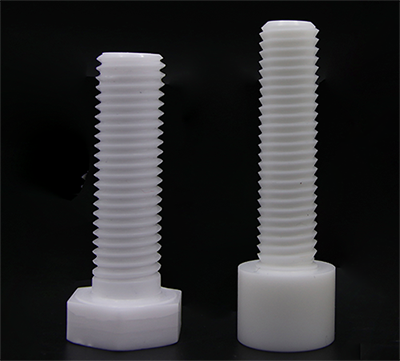

- Prototype production in 3D printing process

- Necessary strength could not be achieved due to manufacturing reasons

- Necessary strength could not be achieved due to manufacturing reasons

- Successful prototype production at project partner BCE using green machining

- 60% higher torsional strength based on ceramic oriented screw design

- Tightening torque for Superbolt (10-14Nm)

- 60% higher torsional strength based on ceramic oriented screw design

Project Data

| Project Duration | 01.06.2014 - 30.11.2016 |

| Sponsor |

Federal Ministry of Economics and Technology (BMWi), Central Innovation Programme for SMEs (ZIM) |

| Funding Amount | 174,500 Euro |

| Project Partners | Fraunhofer-Centre HTL BCE Special Ceramics GmbH |

| Project Coordination | BCE Special Ceramics GmbH |

| Project Management at the HTL |

Marina Stepanyan |

|

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth