Completed funded project

Motivation

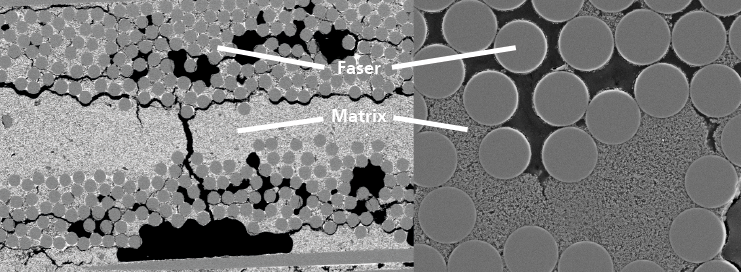

Ceramic Matrix Composites (CMC) are to replace metallic materials in highly stressed parts of gas turbines. The use of CMCs is expected to increase turbine efficiency and reduce weight at the same time. In the future, CMCs can thus make an important contribution to reducing the environmental impact of air traffic. On the basis of developments in the field of oxidic CMC, demonstrators - so-called flower mixers - are being manufactured and tested for specific applications. In addition, the establishment of national testing capacities for CMCs is to be supported, also with a view to subsequent aviation certification of the materials.

Objective

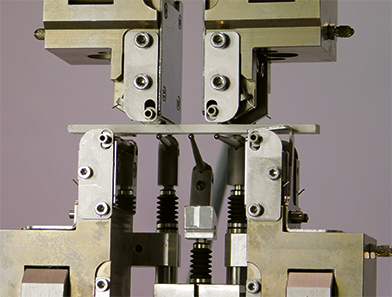

Suspensions for oxide ceramic matrices are to be developed, which can be processed with 2D-fibre fabrics to Ox/Ox-CMC. For this purpose, the rheological properties, the particle sizes and the drying behaviour of the suspensions must be adjusted in such a way that the suspensions can be introduced homogeneously into the fabric without causing damage to the fabric. The HTL will carry out the material characterisation of the CMC and the validation of design elements according to international standards. This will ensure the comparability of the materials and components developed by the project partners during the project. The suitability of the materials for turbine applications will be ensured by material tests according to international aviation-relevant standards.

Results

- Development of an O-CMC material according to the specifications of Rolls-Royce Deutschland Ltd & Co. KG

- Determination of process stability (fiber type, matrix type, fiber volume content, sintering temperature) and its effect on mechanical properties

- Process stability DoE with statistical design of experiments and statistical evaluation

- Manufacturing of two feature samples / one bloom mixer study including mold making, ply-book development, fiber cutting and part finishing

Project Data

| Project Duration | 01.11.2018 - 30.11.2022 |

| Sponsor | Federal Ministry of Education and Research |

| Funding Amount | 371,000 Euro |

| Project Partners | Fraunhofer Center HTL ArianeGroup MTU Aero Engines AG BJS Ceramics GmbH Schunk GmbH & Co. KG German Aerospace Center Rolls-Royce Motor Cars Ltd. |

| Project Coordination | Fraunhofer Center HTL |

| Project Management at the HTL |

Arne Rüdinger, Wolfgang Bernstein |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth