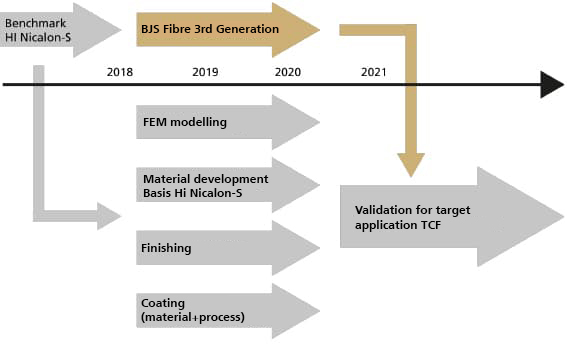

Completed funded project

Motivation

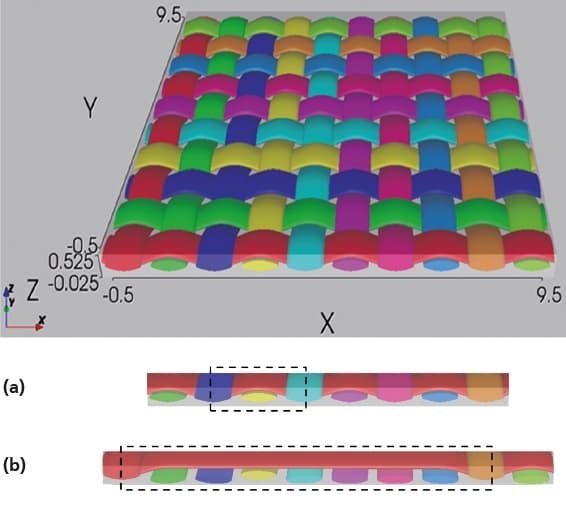

Classic dense canvas fabric structure (a) as well as 8-bond atlas fabric adapted to SiC fibres with fibre-friendly reduction of fibre deflections (b)

New CMC materials can contribute to increasing the efficiency of gas turbines while reducing component weight. Thus, with the help of high-temperature stable and long-term resistant CMC materials, the cycle process can be optimised to higher operating temperatures without the need for additional cooling air. This actively supports the objectives for an environmentally friendly air traffic according to the European R&I strategy Flightpath 2050. The project will contribute to the development of processes for the production of SiC/SiC-CMC. This CMC is expected to increase the temperature range by > 100 K that is currently achievable in metallic construction.

Objective

- Multi-scale, probalistic design method for CMC

- Functional fibre coating

- Development of load-compatible 2.5 D fibre preforms

- Processing of novel SiC fibres

- Homogeneous and dense SiC-matrix by liquid silicification

- Efficient machinig technology for features and functional surfaces

Results

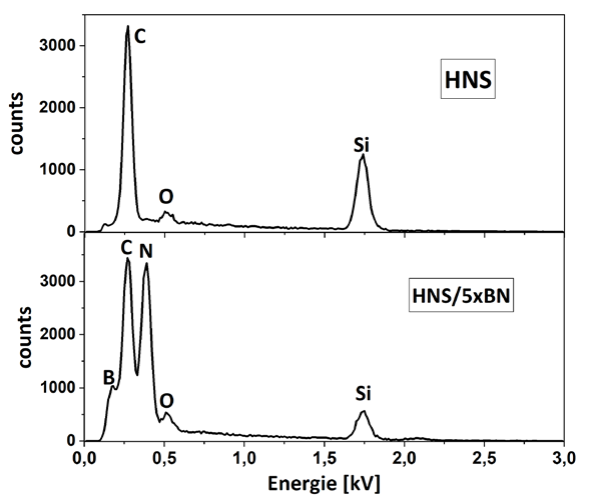

EDX spectra of a non-coated SiC fibre (top) and one coated with 5-fold BN. SiC fibre (bottom). HNS is the abbreviation for the SiC fibre "Hi Nicalon Type S".

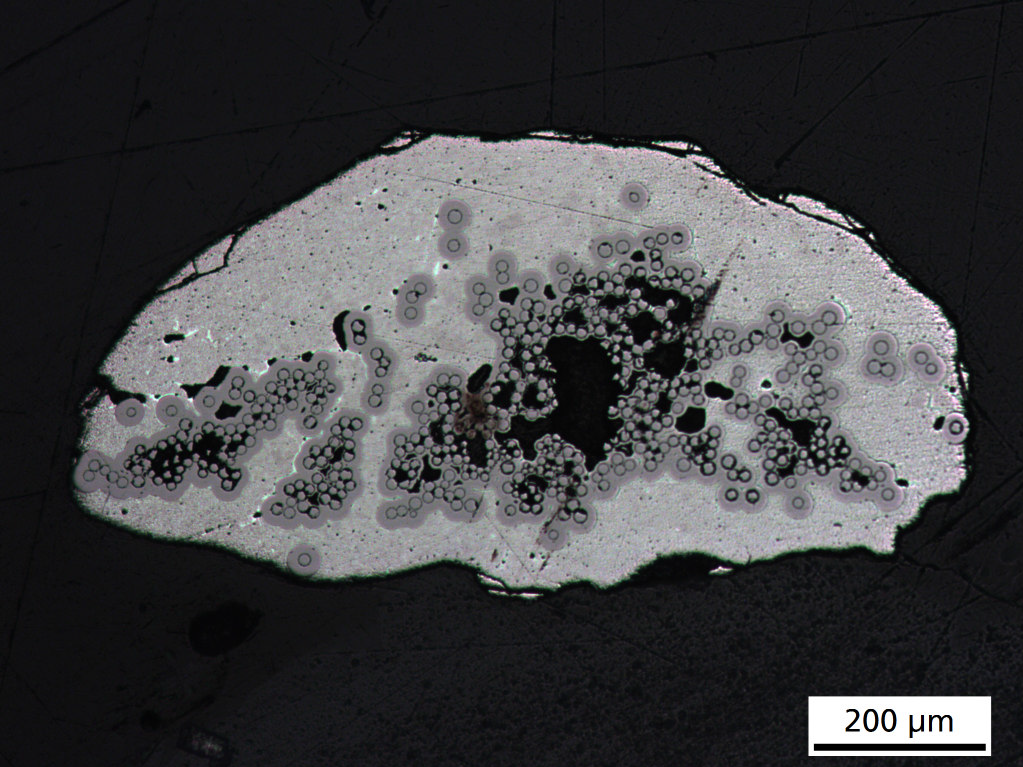

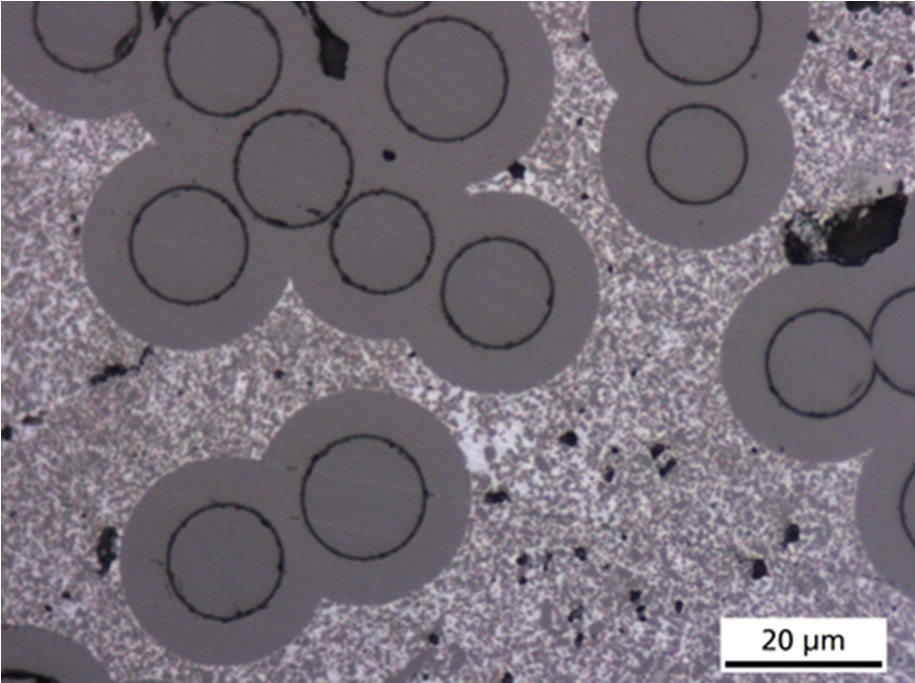

20 cm mini composite MK4 made from series 3 with intact SiC fibre cross-sections, LIMI cross-section with 100x magnification.

Fully preserved SiC fibres embedded in a SiSiC matrix in 200 mm long MK5 series 3 minicomposite. LIMI image, 1000x magnification.

Fibre and component coating

- Wet chemical fibre and component coating: BN/SiC double coating on HN-type S SiC fibres

- BN as crystalline hexagonal modification; free of oxygen, layer thickness 120 nm with 5-fold coating application

- SiC layers over polysilane-polycarbosilane copolymer layer thickness 60 ± 20 nm with 8-fold layer application

Preform and matrix production

- Development of a load-capable 2.5 D fibre preform of type SiC-F3 from modification of a commercial fabric

- Type SiC F3 roving thickness in the silicided preform with approx. 0.11 mm is 27 % smaller, the roving width with approx. 1.27 mm is larger but 25 % larger than the commercial variant -> easier matrix build-up due to shorter infiltration paths

Production of mini-composites

- For the first time, mechanically testable 20 cm long silicided SiC/SiC minicomposites have been successfully produced.

- SiC fibres protected from attack by the silicon melt by intelligent process control and adapted fibre coating during liquid silicification

- the roughness of the minicomposites improved considerably: surfaces of commercially silicided CMC (brake discs) show maximum roughness Rmax of 75µm -> surface of the minicomposites a Rmax value of 6µm

Project Data

| Project Duration | 01.11.2018 - 31.12.2021 |

| Sponsor | Federal Ministry of Education and Research |

| Funding Amount | 200,000 Euro |

| Project Partners | Fraunhofer-Centre HTL Fraunhofer IKTS Fraunhofer IPK Fraunhofer IWM MTU Aero Engines AG Schunk GmbH & Co. KG German Aerospace Centre BJS Ceramics GmbH T-ZfP |

| Project Coordination | MTU Aero Engines AG |

| Project Management at the HTL |

Dr. Alexander Konschak |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth