Completed funded project

Motivation

The field of application of oxidic fibre composite ceramics (O-CMC) is constantly expanding. This material class is established in many special high-temperature applications for which only small quantities are required. Potential applications, such as components for gas turbines, will go beyond the scale of small series production. In future, such components will have to be produced using series production technologies that have not been available to date.

Objective

The project was to develop a prepreg technology suitable for series production, preferably based on established processes from CFRP production, with which O-CMC components can be used for sintering and bonding.

temperatures < 1200 °C can be produced. The requirements for O-CMC materials made of Al2O3 fibres and a matrix system of Al2O3-ZrO2 were bending strength > 200 MPa, interlaminar shear strength > 14 MPa and elongation at break > 0.3 %. The mechanical properties of the O-CMC components manufactured on the basis of the prepreg technology developed were to have a significantly lower scattering and thus higher reproducibility than components currently manufactured by hand.

Results

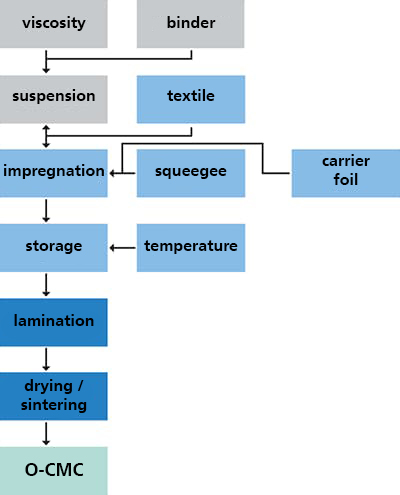

- Development of aqueous ceramic suspensions for the prepreg process

- The properties of the suspension were adapted by varying the binder systems / PVA molar mass and degree of saponification

- The properties of the suspension were adapted by varying the binder systems / PVA molar mass and degree of saponification

- Development of infiltration technology for prepreg production

- Development and construction of a manual prepreg foulard coater plant and installation at the project partner

- Development and construction of a manual prepreg foulard coater plant and installation at the project partner

- Determination of the storage properties of infiltrated prepregs

- Prepregs can be stored for weeks at room temperature or in the refrigerator when shrink-wrapped

- Further processing of prepregs into green bodies

- Panel material made of laminated prepregs shows identical mechanical characteristics of the hand laminated benchmark samples

- Pressing technique, autoclave technique, vacuum bag

- Processing of prepregs with the developed matrix system to O-CMC components requires no autoclave or vacuum bag technology

- Simple shaping and drying in press moulds is sufficient

Project Data

| Project Duration | 05.2014 - 04.2016 |

| Sponsor | Federal Ministry of Economics and Energy Central Innovation Programme for SMEs (ZIM) |

| Funding Amount |

175,000 Euro |

| Project Partner | Fraunhofer-Centre HTL Walter E. C. Pritzkow Spezialkeramik |

| Project Coordination | Fraunhofer-Centre HTL |

| Project Managemant at the HTL | Arne Rüdinger |

|

|

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth