Completed funded project

Motivation

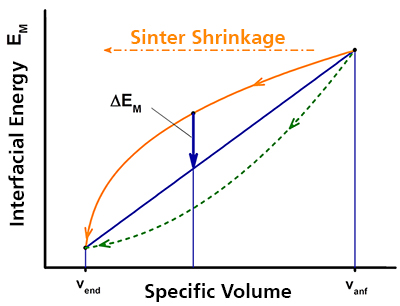

For high-performance ceramic materials, reliability is crucial in many fields of application, such as the automotive sector. Due to thermodynamically driven segregation processes during sintering and the resulting inhomogeneous microstructure, however, the reliability of sintered ceramics often falls far short of the theoretically possible potential. The formation of these inhomogeneities can be prevented if inherently safe sintering conditions are found, in which the interfacial energy of the microstructure decreases at least as fast as its specific volume during compaction.

Objective

In the Isi2Ker project inherently safe sintering processes for aluminium oxide ceramics were to be developed. The homogeneous microstructure that can be achieved with this process should guarantee the reliability of the sintered

ceramics significantly compared to the state of the art. The performance of the process was to be improved for alumina of different purities on the basis of selected components from the product portfolio of the three participating industrial partners.

Results

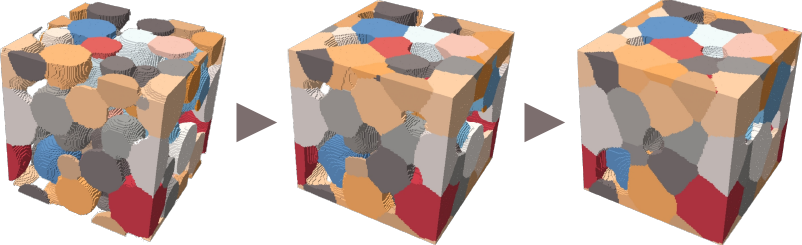

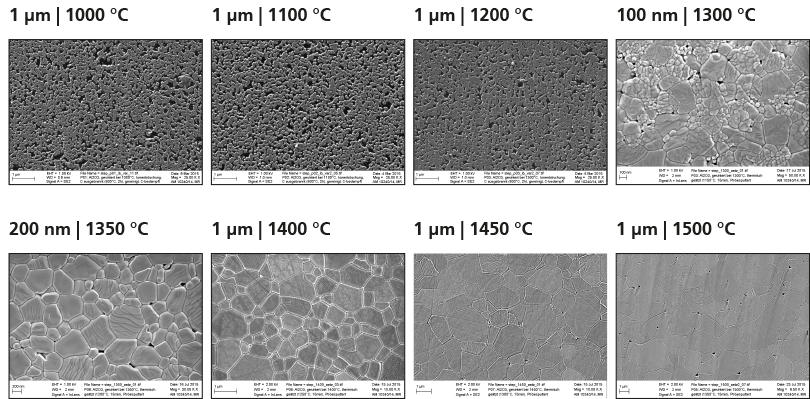

First, the actual state of the structural homogeneities and the resulting strength and reliability in all cases were determined. Then the shaping processes were optimised to ensure the best possible homogeneous microstructure in the green state as a starting point for the sintering process. With the aid of computer simulations and laboratory experiments adapted to these, it was then investigated which conditions during sintering (in particular temperature control and furnace atmosphere) most effectively prevent the formation of inhomogeneities. As a result, by transferring the knowledge gained on shaping processes and sintering conditions to industrial production processes, a significant increase in strength and/or reliability of the alumina components was achieved in all cases. However, it has also been shown that the full potential of strength of concrete products due to the homogeneous microstructure can only be exploited by additional measures such as low-defect grinding and polishing and, if necessary, post-compaction (by hot isostatic pressing).

Project Data

| Project Duration | 01.01.2016 - 31.12.2019 |

| Sponsor |

Bavarian Research Foundation |

| Funding Amount HTL | 409,100 Euro |

| Project Partner | Fraunhofer-Centre HTL CeramTec GmbH Sembach Technical Ceramics GmbH & Co. KG Döbrich & Heckel Steatitwerke GmbH & Co. KG |

| Project Coordination |

Fraunhofer-Centre HTL |

| Project Management at the HTL | Dr. Gerhard Seifert |

|

|

|

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth