Completed funded project

Motivation

Heating dishes by induction makes it possible to keep food warm directly on the plate or other serving vessel in an energy-saving and hygienic way or to heat it up specifically before consumption. This option is increasingly being used in the restaurant and catering sector and in larger facilities such as hospitals or nursing homes. The induction tableware currently available on the market uses only metallic layers for coupling to the electromagnetic field, which must be subsequently applied to the non-conductive porcelain or other ceramic tableware. The very different expansion coefficients of metal and porcelain limit the

so far the applicability of induction cookware.

Objective

The aim of this project was to develop ceramic products that can be heated by electromagnetic induction without the use of metallic components. Instead of the silver layers used to date, which require an additional work step (decorating with a metal layer and decorative firing), purely ceramic materials were to be developed for the inductive heating effect. An important sub-goal was also to better adapt the thermal expansion coefficients of the heating layer and product (e.g. plate). Overall, the purely ceramic materials should not only make induction-heated products more cost-effective (due to cheaper raw materials and higher energy efficiency during production), but also significantly more flexible in terms of functionality and design.

Results

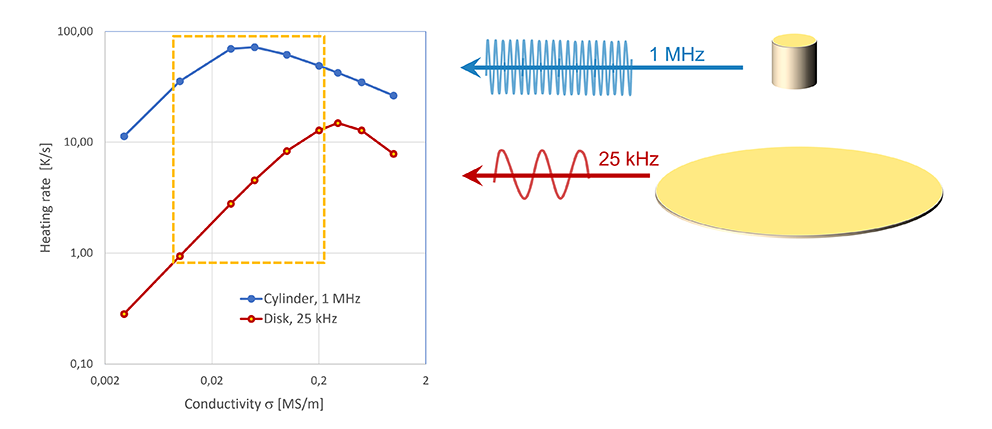

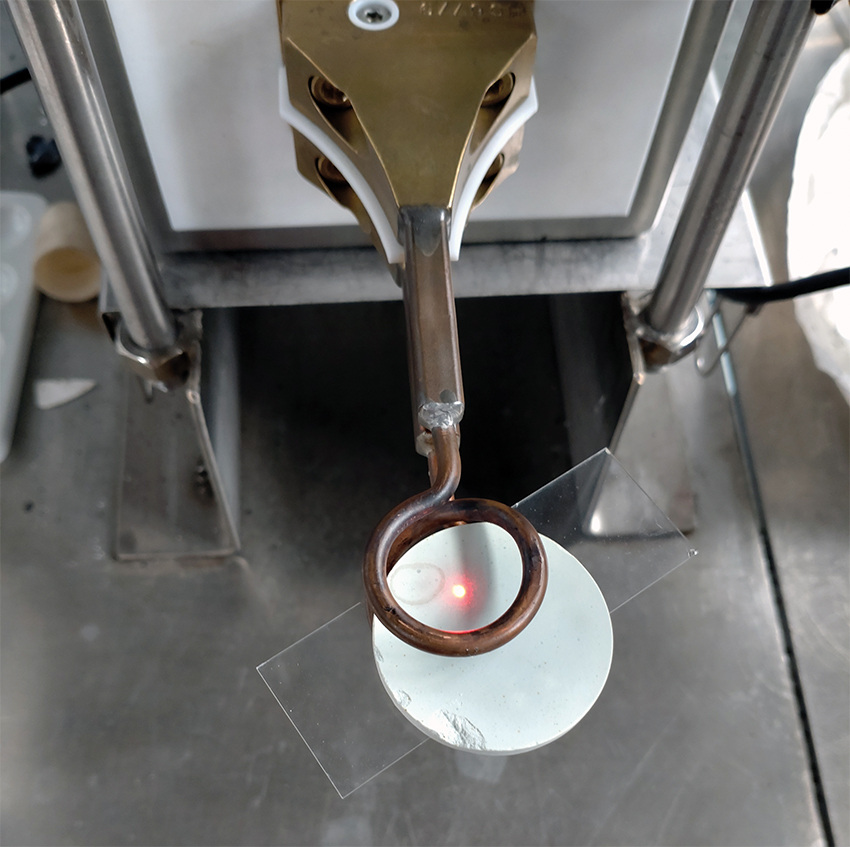

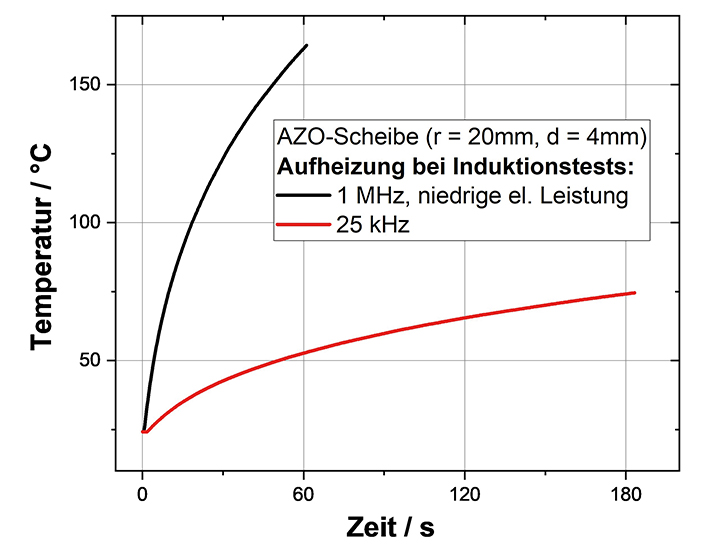

In the project, a purely oxidic, sintered ceramic (material variant of aluminum-doped zinc oxide - AZO) was developed in an interplay of research, experiments and simulations, which can be heated inductively via eddy currents. Thanks to good electrical conductivity and a thermal expansion very similar to porcelain, the material is very suitable as a heating layer for induction cookware. Even at low induction frequencies of 25 kHz, which are also common in private households, heating capacities of 100 W and more can be easily achieved with typical geometries (e.g. 20 cm diameter disc, 1 mm thick). However, a joint firing of porcelain and heating layer is not possible due to strong chemical interaction in the thermal process, i.e. a joining or bonding process is still necessary for real application.

Project Data

| Project Duration | 01.07.2020 - 31.12.2023 |

| Sponsor | Bavarian State Ministry of Economic Affairs, Regional Development and Energy |

| Funding Amount | 250,000 Euro |

| Project Partners | Fraunhofer Center HTL BHS tabletop GmbH |

| Project Coordination | Fraunhofer Center HTL |

| Project Management at the HTL | Dr. Gerhard Seifert |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth