Completed funded project

Motivation

Within the framework of the preceding BMBF project "Resource-efficient fibre-coated steel pipes for ultra-high-temperature steam applications", basic concepts and procedures for reinforcing superheated steam pipes with ceramic composite materials (CMC) were developed. It could be proven that the creep deformation of steel hot steam pipes under supercritical conditions is effectively hindered by the ceramic reinforcement. The feasibility of an on-site reinforcement of power plant pipes was demonstrated by a field test in the "Großkraftwerk Mannheim".

Objective

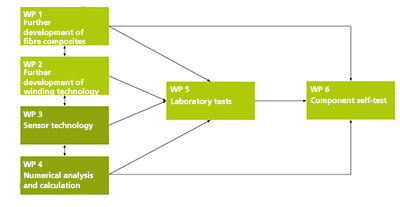

The reinforcement of an entire power plant pipeline comes with challenges such as having to reinforce preexisting pipe geometry (vast length of the pipelines, pipe curvature, variable pipe cross-section, outlets) as well as the quality of the reinforcement. The objective of the joint project is to develop the prerequisites for the technical implementation of CMC reinforcements in the power plant sector.

Results

- Development of application-oriented fibre prepregs for CMC reinforcement of power plant pipes

- Proof of reproducible mechanical prepreg production

- Successful development of a semi-automated CMC reinforcement method for pipes

- Evaluation of different non-destructive on-site testing methods

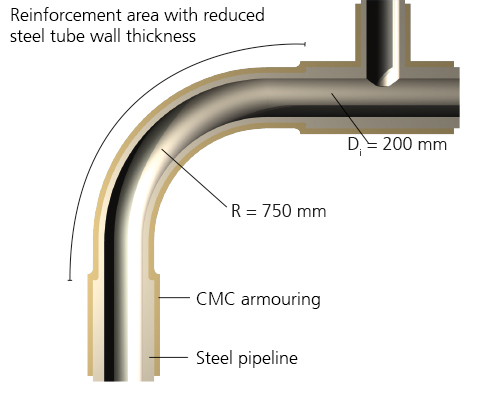

- CMC armouring of a large-format steel pipeline bend in cooperation with the project partners

- Successful application testing of the CMC-reinforced pipe bend in the large-scale power plant in Mannheim (component field test)

- Proof of the effectiveness of the CMC reinforcement in the component field test

Project Data

| Project Duration | 01.10.2015 - 30.09.2021 |

| Sponsor | Bundesministerium für Wirtschaft und Energie, COORETEC-Initiative des 6. Energieforschungsprogramms |

| Funding Amount | 276,000 Euro |

| Project Partners | Fraunhofer-Centre HTL Bilfinger Piping Technologies GmbH Großkraftwerk Mannheim AG Material Testing Institute University of Stuttgart Schunk Kohlenstofftechnik GmbH Technion - Israel Institute of Technology TÜV SÜD Industrie Service GmbH University of Bayreuth (Ceramic Materials Engineering) |

| Project Coordination | Fraunhofer-Centre HTL |

| Project Management at the HTL |

Christian Eckardt |

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth