Completed funded project

Motivation

Kiln furniture is indispensable in the manufacture of ceramic products as supports for the components in the kiln. However, kiln furniture - just like the products to be manufactured - has to be heated up, which has a negative effect on energy consumption and thus also on CO2 emissions. Depending on the process, they account for up to 80 % of the kiln load. Energy consumption can be reduced by reducing the mass of the kiln furniture to give it a low heat capacity. A reduction in mass can be realised by a thinner-walled kiln furniture design and/or by increasing the porosity of the materials.

Objective

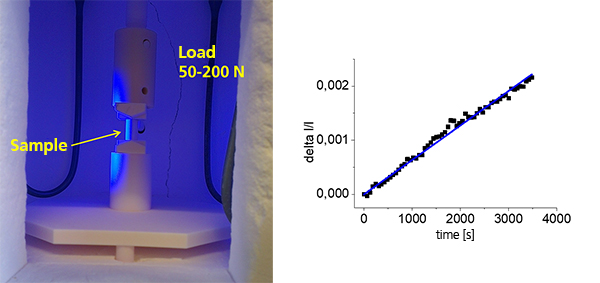

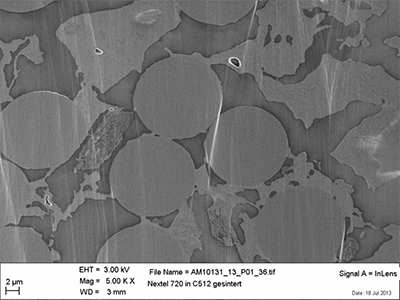

Results

In the context of the project, the approach was pursued to improve the mechanical and thermomechanical properties of the kiln furniture by fibre reinforcement and optimisation of the material microstructure in such a way that the kiln furniture can be equipped with less mass for the same performance. This made it possible to save energy in the kiln processes during the manufacturing of components.

Project Data

| Project Duration | 01.10.2012 - 30.09.2015 |

| Sponsor | Bavarian State Ministry of Economic Affairs, Transport and Technology; "New Materials in Bavaria" programme |

| Funding Amount | 350,000 Euro |

| Project Partners |

Fraunhofer-Centre HTL Rauschert Steinbach GmbH |

| Project Coordination | Rauschert Steinbach GmbH |

| Project Management at the HTL |

Dr. Andreas Nöth |

|

|

|

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth

Fraunhofer ISC, Center for High Temperature Materials and Design HTL, Bayreuth